Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

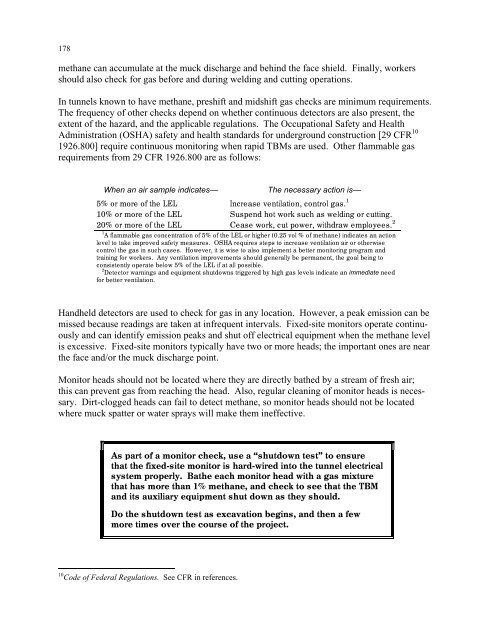

178methane can accumulate at the muck discharge and beh<strong>in</strong>d the face shield. F<strong>in</strong>ally, workersshould also check <strong>for</strong> gas be<strong>for</strong>e and dur<strong>in</strong>g weld<strong>in</strong>g and cutt<strong>in</strong>g operations.In tunnels known to have methane, preshift and midshift gas checks are m<strong>in</strong>imum requirements.The frequency of other checks depend on whether cont<strong>in</strong>uous detectors are also present, theextent of the hazard, and the applicable regulations. The Occupational Safety and HealthAdm<strong>in</strong>istration (OSHA) safety and health standards <strong>for</strong> underground construction [29 CFR 101926.800] require cont<strong>in</strong>uous monitor<strong>in</strong>g when rapid TBMs are used. Other flammable gasrequirements from 29 CFR 1926.800 are as follows:When an air sample <strong>in</strong>dicates—The necessary action is—5% or more of the LEL Increase ventilation, control gas. 110% or more of the LEL Suspend hot work such as weld<strong>in</strong>g or cutt<strong>in</strong>g.20% or more of the LEL Cease work, cut power, withdraw employees. 21A flammable gas concentration of 5% of the LEL or higher (0.25 vol % of methane) <strong>in</strong>dicates an actionlevel to take improved safety measures. OSHA requires steps to <strong>in</strong>crease ventilation air or otherwisecontrol the gas <strong>in</strong> such cases. However, it is wise to also implement a better monitor<strong>in</strong>g program andtra<strong>in</strong><strong>in</strong>g <strong>for</strong> workers. Any ventilation improvements should generally be permanent, the goal be<strong>in</strong>g toconsistently operate below 5% of the LEL if at all possible.2Detector warn<strong>in</strong>gs and equipment shutdowns triggered by high gas levels <strong>in</strong>dicate an immediate need<strong>for</strong> better ventilation.Handheld detectors are used to check <strong>for</strong> gas <strong>in</strong> any location. However, a peak emission can bemissed because read<strong>in</strong>gs are taken at <strong>in</strong>frequent <strong>in</strong>tervals. Fixed-site monitors operate cont<strong>in</strong>uouslyand can identify emission peaks and shut off electrical equipment when the methane levelis excessive. Fixed-site monitors typically have two or more heads; the important ones are nearthe face and/or the muck discharge po<strong>in</strong>t.Monitor heads should not be located where they are directly bathed by a stream of fresh air;this can prevent gas from reach<strong>in</strong>g the head. Also, regular clean<strong>in</strong>g of monitor heads is necessary.Dirt-clogged heads can fail to detect methane, so monitor heads should not be locatedwhere muck spatter or water sprays will make them <strong>in</strong>effective.As part of a monitor check, use a “shutdown test” to ensurethat the fixed-site monitor is hard-wired <strong>in</strong>to the tunnel electricalsystem properly. Bathe each monitor head with a gas mixturethat has more than 1% methane, and check to see that the TBMand its auxiliary equipment shut down as they should.Do the shutdown test as excavation beg<strong>in</strong>s, and then a fewmore times over the course of the project.10 Code of Federal Regulations. See CFR <strong>in</strong> references.