Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

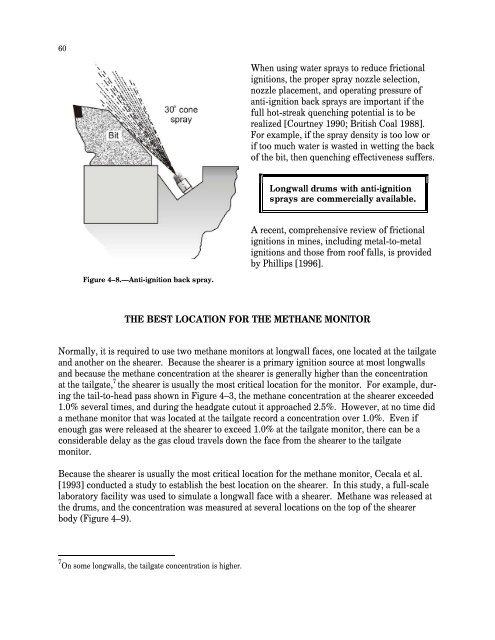

60When us<strong>in</strong>g water sprays to reduce frictionalignitions, the proper spray nozzle selection,nozzle placement, and operat<strong>in</strong>g pressure ofanti-ignition back sprays are important if thefull hot-streak quench<strong>in</strong>g potential is to berealized [Courtney 1990; British Coal 1988].For example, if the spray density is too low orif too much water is wasted <strong>in</strong> wett<strong>in</strong>g the backof the bit, then quench<strong>in</strong>g effectiveness suffers.Longwall drums with anti-ignitionsprays are commercially available.A recent, comprehensive review of frictionalignitions <strong>in</strong> m<strong>in</strong>es, <strong>in</strong>clud<strong>in</strong>g metal-to-metalignitions and those from roof falls, is providedby Phillips [1996].Figure 4–8.—Anti-ignition back spray.THE BEST LOCATION FOR THE METHANE MONITORNormally, it is required to use two methane monitors at longwall faces, one located at the tailgateand another on the shearer. Because the shearer is a primary ignition source at most longwallsand because the methane concentration at the shearer is generally higher than the concentrationat the tailgate, 7 the shearer is usually the most critical location <strong>for</strong> the monitor. For example, dur<strong>in</strong>gthe tail-to-head pass shown <strong>in</strong> Figure 4–3, the methane concentration at the shearer exceeded1.0% several times, and dur<strong>in</strong>g the headgate cutout it approached 2.5%. However, at no time dida methane monitor that was located at the tailgate record a concentration over 1.0%. Even ifenough gas were released at the shearer to exceed 1.0% at the tailgate monitor, there can be aconsiderable delay as the gas cloud travels down the face from the shearer to the tailgatemonitor.Because the shearer is usually the most critical location <strong>for</strong> the methane monitor, Cecala et al.[1993] conducted a study to establish the best location on the shearer. In this study, a full-scalelaboratory facility was used to simulate a longwall face with a shearer. <strong>Methane</strong> was released atthe drums, and the concentration was measured at several locations on the top of the shearerbody (Figure 4–9).7 On some longwalls, the tailgate concentration is higher.