Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

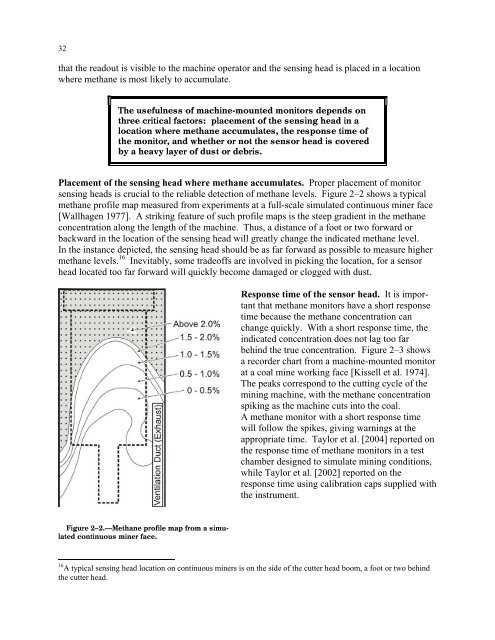

32that the readout is visible to the mach<strong>in</strong>e operator and the sens<strong>in</strong>g head is placed <strong>in</strong> a locationwhere methane is most likely to accumulate.The usefulness of mach<strong>in</strong>e-mounted monitors depends onthree critical factors: placement of the sens<strong>in</strong>g head <strong>in</strong> alocation where methane accumulates, the response time ofthe monitor, and whether or not the sensor head is coveredby a heavy layer of dust or debris.Placement of the sens<strong>in</strong>g head where methane accumulates. Proper placement of monitorsens<strong>in</strong>g heads is crucial to the reliable detection of methane levels. Figure 2–2 shows a typicalmethane profile map measured from experiments at a full-scale simulated cont<strong>in</strong>uous m<strong>in</strong>er face[Wallhagen 1977]. A strik<strong>in</strong>g feature of such profile maps is the steep gradient <strong>in</strong> the methaneconcentration along the length of the mach<strong>in</strong>e. Thus, a distance of a foot or two <strong>for</strong>ward orbackward <strong>in</strong> the location of the sens<strong>in</strong>g head will greatly change the <strong>in</strong>dicated methane level.In the <strong>in</strong>stance depicted, the sens<strong>in</strong>g head should be as far <strong>for</strong>ward as possible to measure highermethane levels. 16 Inevitably, some tradeoffs are <strong>in</strong>volved <strong>in</strong> pick<strong>in</strong>g the location, <strong>for</strong> a sensorhead located too far <strong>for</strong>ward will quickly become damaged or clogged with dust.Response time of the sensor head. It is importantthat methane monitors have a short responsetime because the methane concentration canchange quickly. With a short response time, the<strong>in</strong>dicated concentration does not lag too farbeh<strong>in</strong>d the true concentration. Figure 2–3 showsa recorder chart from a mach<strong>in</strong>e-mounted monitorat a coal m<strong>in</strong>e work<strong>in</strong>g face [Kissell et al. 1974].The peaks correspond to the cutt<strong>in</strong>g cycle of them<strong>in</strong><strong>in</strong>g mach<strong>in</strong>e, with the methane concentrationspik<strong>in</strong>g as the mach<strong>in</strong>e cuts <strong>in</strong>to the coal.A methane monitor with a short response timewill follow the spikes, giv<strong>in</strong>g warn<strong>in</strong>gs at theappropriate time. Taylor et al. [2004] reported onthe response time of methane monitors <strong>in</strong> a testchamber designed to simulate m<strong>in</strong><strong>in</strong>g conditions,while Taylor et al. [2002] reported on theresponse time us<strong>in</strong>g calibration caps supplied withthe <strong>in</strong>strument.Figure 2–2.—<strong>Methane</strong> profile map from a simulatedcont<strong>in</strong>uous m<strong>in</strong>er face.16 A typical sens<strong>in</strong>g head location on cont<strong>in</strong>uous m<strong>in</strong>ers is on the side of the cutter head boom, a foot or two beh<strong>in</strong>dthe cutter head.