Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

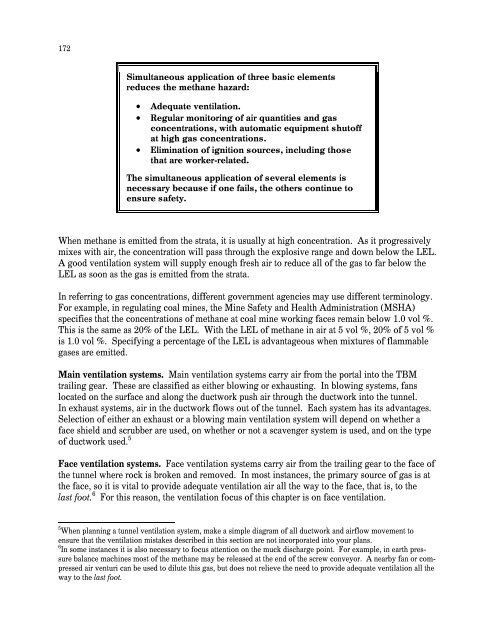

172Simultaneous application of three basic elementsreduces the methane hazard:• Adequate ventilation.• Regular monitor<strong>in</strong>g of air quantities and gasconcentrations, with automatic equipment shutoffat high gas concentrations.• Elim<strong>in</strong>ation of ignition sources, <strong>in</strong>clud<strong>in</strong>g thosethat are worker-related.The simultaneous application of several elements isnecessary because if one fails, the others cont<strong>in</strong>ue toensure safety.When methane is emitted from the strata, it is usually at high concentration. As it progressivelymixes with air, the concentration will pass through the explosive range and down below the LEL.A good ventilation system will supply enough fresh air to reduce all of the gas to far below theLEL as soon as the gas is emitted from the strata.In referr<strong>in</strong>g to gas concentrations, different government agencies may use different term<strong>in</strong>ology.For example, <strong>in</strong> regulat<strong>in</strong>g coal m<strong>in</strong>es, the M<strong>in</strong>e Safety and Health Adm<strong>in</strong>istration (MSHA)specifies that the concentrations of methane at coal m<strong>in</strong>e work<strong>in</strong>g faces rema<strong>in</strong> below 1.0 vol %.This is the same as 20% of the LEL. With the LEL of methane <strong>in</strong> air at 5 vol %, 20% of 5 vol %is 1.0 vol %. Specify<strong>in</strong>g a percentage of the LEL is advantageous when mixtures of flammablegases are emitted.Ma<strong>in</strong> ventilation systems. Ma<strong>in</strong> ventilation systems carry air from the portal <strong>in</strong>to the TBMtrail<strong>in</strong>g gear. These are classified as either blow<strong>in</strong>g or exhaust<strong>in</strong>g. In blow<strong>in</strong>g systems, fanslocated on the surface and along the ductwork push air through the ductwork <strong>in</strong>to the tunnel.In exhaust systems, air <strong>in</strong> the ductwork flows out of the tunnel. Each system has its advantages.Selection of either an exhaust or a blow<strong>in</strong>g ma<strong>in</strong> ventilation system will depend on whether aface shield and scrubber are used, on whether or not a scavenger system is used, and on the typeof ductwork used. 5Face ventilation systems. Face ventilation systems carry air from the trail<strong>in</strong>g gear to the face ofthe tunnel where rock is broken and removed. In most <strong>in</strong>stances, the primary source of gas is atthe face, so it is vital to provide adequate ventilation air all the way to the face, that is, to thelast foot. 6 For this reason, the ventilation focus of this chapter is on face ventilation.5 When plann<strong>in</strong>g a tunnel ventilation system, make a simple diagram of all ductwork and airflow movement toensure that the ventilation mistakes described <strong>in</strong> this section are not <strong>in</strong>corporated <strong>in</strong>to your plans.6 In some <strong>in</strong>stances it is also necessary to focus attention on the muck discharge po<strong>in</strong>t. For example, <strong>in</strong> earth pressurebalance mach<strong>in</strong>es most of the methane may be released at the end of the screw conveyor. A nearby fan or compressedair venturi can be used to dilute this gas, but does not relieve the need to provide adequate ventilation all theway to the last foot.