Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

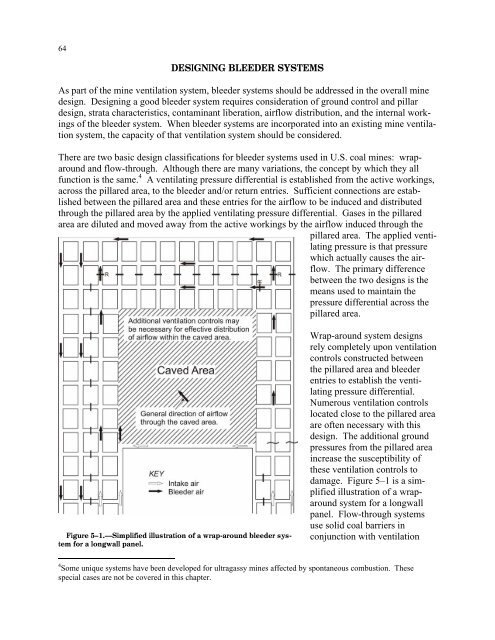

64DESIGNING BLEEDER SYSTEMSAs part of the m<strong>in</strong>e ventilation system, bleeder systems should be addressed <strong>in</strong> the overall m<strong>in</strong>edesign. Design<strong>in</strong>g a good bleeder system requires consideration of ground control and pillardesign, strata characteristics, contam<strong>in</strong>ant liberation, airflow distribution, and the <strong>in</strong>ternal work<strong>in</strong>gsof the bleeder system. When bleeder systems are <strong>in</strong>corporated <strong>in</strong>to an exist<strong>in</strong>g m<strong>in</strong>e ventilationsystem, the capacity of that ventilation system should be considered.There are two basic design classifications <strong>for</strong> bleeder systems used <strong>in</strong> U.S. coal m<strong>in</strong>es: wraparoundand flow-through. Although there are many variations, the concept by which they allfunction is the same. 4 A ventilat<strong>in</strong>g pressure differential is established from the active work<strong>in</strong>gs,across the pillared area, to the bleeder and/or return entries. Sufficient connections are establishedbetween the pillared area and these entries <strong>for</strong> the airflow to be <strong>in</strong>duced and distributedthrough the pillared area by the applied ventilat<strong>in</strong>g pressure differential. Gases <strong>in</strong> the pillaredarea are diluted and moved away from the active work<strong>in</strong>gs by the airflow <strong>in</strong>duced through thepillared area. The applied ventilat<strong>in</strong>gpressure is that pressurewhich actually causes the airflow.The primary differencebetween the two designs is themeans used to ma<strong>in</strong>ta<strong>in</strong> thepressure differential across thepillared area.Figure 5–1.—Simplified illustration of a wrap-around bleeder system<strong>for</strong> a longwall panel.Wrap-around system designsrely completely upon ventilationcontrols constructed betweenthe pillared area and bleederentries to establish the ventilat<strong>in</strong>gpressure differential.Numerous ventilation controlslocated close to the pillared areaare often necessary with thisdesign. The additional groundpressures from the pillared area<strong>in</strong>crease the susceptibility ofthese ventilation controls todamage. Figure 5–1 is a simplifiedillustration of a wraparoundsystem <strong>for</strong> a longwallpanel. Flow-through systemsuse solid coal barriers <strong>in</strong>conjunction with ventilation4 Some unique systems have been developed <strong>for</strong> ultragassy m<strong>in</strong>es affected by spontaneous combustion. Thesespecial cases are not be covered <strong>in</strong> this chapter.