Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

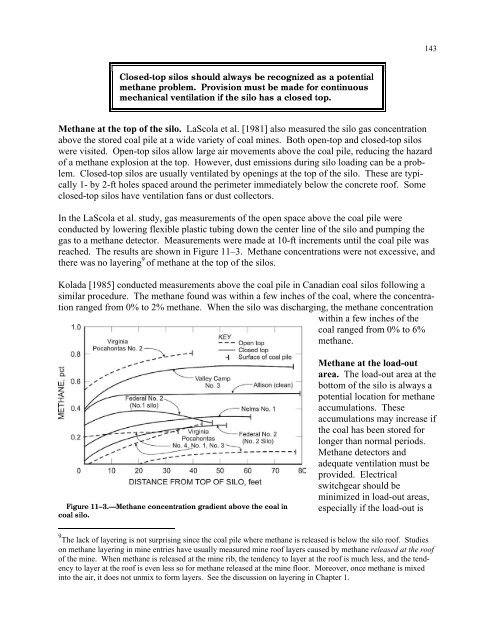

143Closed-top silos should always be recognized as a potentialmethane problem. Provision must be made <strong>for</strong> cont<strong>in</strong>uousmechanical ventilation if the silo has a closed top.<strong>Methane</strong> at the top of the silo. LaScola et al. [1981] also measured the silo gas concentrationabove the stored coal pile at a wide variety of coal m<strong>in</strong>es. Both open-top and closed-top siloswere visited. Open-top silos allow large air movements above the coal pile, reduc<strong>in</strong>g the hazardof a methane explosion at the top. However, dust emissions dur<strong>in</strong>g silo load<strong>in</strong>g can be a problem.Closed-top silos are usually ventilated by open<strong>in</strong>gs at the top of the silo. These are typically1- by 2-ft holes spaced around the perimeter immediately below the concrete roof. Someclosed-top silos have ventilation fans or dust collectors.In the LaScola et al. study, gas measurements of the open space above the coal pile wereconducted by lower<strong>in</strong>g flexible plastic tub<strong>in</strong>g down the center l<strong>in</strong>e of the silo and pump<strong>in</strong>g thegas to a methane detector. Measurements were made at 10-ft <strong>in</strong>crements until the coal pile wasreached. The results are shown <strong>in</strong> Figure 11–3. <strong>Methane</strong> concentrations were not excessive, andthere was no layer<strong>in</strong>g 9 of methane at the top of the silos.Kolada [1985] conducted measurements above the coal pile <strong>in</strong> Canadian coal silos follow<strong>in</strong>g asimilar procedure. The methane found was with<strong>in</strong> a few <strong>in</strong>ches of the coal, where the concentrationranged from 0% to 2% methane. When the silo was discharg<strong>in</strong>g, the methane concentrationwith<strong>in</strong> a few <strong>in</strong>ches of thecoal ranged from 0% to 6%methane.Figure 11–3.—<strong>Methane</strong> concentration gradient above the coal <strong>in</strong>coal silo.<strong>Methane</strong> at the load-outarea. The load-out area at thebottom of the silo is always apotential location <strong>for</strong> methaneaccumulations. Theseaccumulations may <strong>in</strong>crease ifthe coal has been stored <strong>for</strong>longer than normal periods.<strong>Methane</strong> detectors andadequate ventilation must beprovided. Electricalswitchgear should bem<strong>in</strong>imized <strong>in</strong> load-out areas,especially if the load-out is9 The lack of layer<strong>in</strong>g is not surpris<strong>in</strong>g s<strong>in</strong>ce the coal pile where methane is released is below the silo roof. Studieson methane layer<strong>in</strong>g <strong>in</strong> m<strong>in</strong>e entries have usually measured m<strong>in</strong>e roof layers caused by methane released at the roofof the m<strong>in</strong>e. When methane is released at the m<strong>in</strong>e rib, the tendency to layer at the roof is much less, and the tendencyto layer at the roof is even less so <strong>for</strong> methane released at the m<strong>in</strong>e floor. Moreover, once methane is mixed<strong>in</strong>to the air, it does not unmix to <strong>for</strong>m layers. See the discussion on layer<strong>in</strong>g <strong>in</strong> Chapter 1.