Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

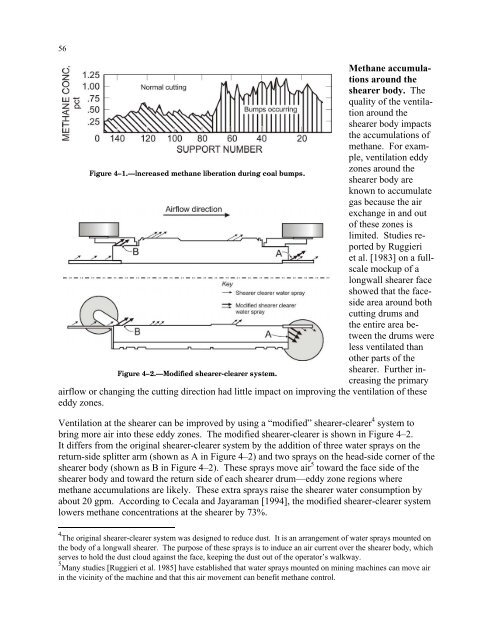

56<strong>Methane</strong> accumulationsaround theshearer body. Thequality of the ventilationaround theshearer body impactsthe accumulations ofmethane. For example,ventilation eddyzones around theFigure 4–1.—Increased methane liberation dur<strong>in</strong>g coal bumps.shearer body areknown to accumulategas because the airexchange <strong>in</strong> and outof these zones islimited. Studies reportedby Ruggieriet al. [1983] on a fullscalemockup of alongwall shearer faceshowed that the facesidearea around bothcutt<strong>in</strong>g drums andthe entire area betweenthe drums wereless ventilated thanother parts of theshearer. Further <strong>in</strong>creas<strong>in</strong>gthe primaryFigure 4–2.—Modified shearer-clearer system.airflow or chang<strong>in</strong>g the cutt<strong>in</strong>g direction had little impact on improv<strong>in</strong>g the ventilation of theseeddy zones.Ventilation at the shearer can be improved by us<strong>in</strong>g a “modified” shearer-clearer 4 system tobr<strong>in</strong>g more air <strong>in</strong>to these eddy zones. The modified shearer-clearer is shown <strong>in</strong> Figure 4–2.It differs from the orig<strong>in</strong>al shearer-clearer system by the addition of three water sprays on thereturn-side splitter arm (shown as A <strong>in</strong> Figure 4–2) and two sprays on the head-side corner of theshearer body (shown as B <strong>in</strong> Figure 4–2). These sprays move air 5 toward the face side of theshearer body and toward the return side of each shearer drum—eddy zone regions wheremethane accumulations are likely. These extra sprays raise the shearer water consumption byabout 20 gpm. Accord<strong>in</strong>g to Cecala and Jayaraman [1994], the modified shearer-clearer systemlowers methane concentrations at the shearer by 73%.4 The orig<strong>in</strong>al shearer-clearer system was designed to reduce dust. It is an arrangement of water sprays mounted onthe body of a longwall shearer. The purpose of these sprays is to <strong>in</strong>duce an air current over the shearer body, whichserves to hold the dust cloud aga<strong>in</strong>st the face, keep<strong>in</strong>g the dust out of the operator’s walkway.5 Many studies [Ruggieri et al. 1985] have established that water sprays mounted on m<strong>in</strong><strong>in</strong>g mach<strong>in</strong>es can move air<strong>in</strong> the vic<strong>in</strong>ity of the mach<strong>in</strong>e and that this air movement can benefit methane control.