Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

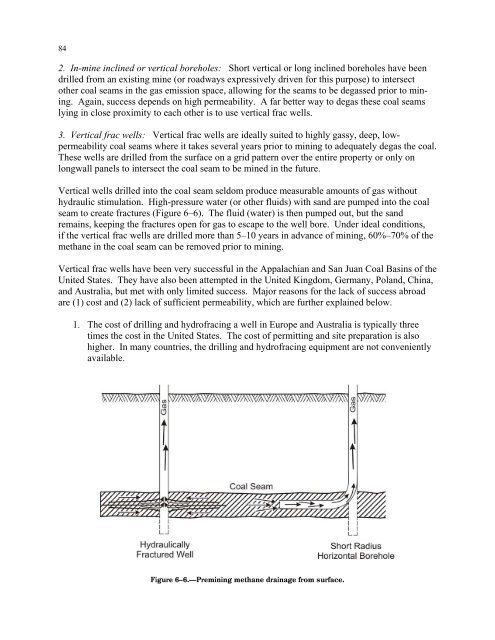

842. In-m<strong>in</strong>e <strong>in</strong>cl<strong>in</strong>ed or vertical boreholes: Short vertical or long <strong>in</strong>cl<strong>in</strong>ed boreholes have beendrilled from an exist<strong>in</strong>g m<strong>in</strong>e (or roadways expressively driven <strong>for</strong> this purpose) to <strong>in</strong>tersectother coal seams <strong>in</strong> the gas emission space, allow<strong>in</strong>g <strong>for</strong> the seams to be degassed prior to m<strong>in</strong><strong>in</strong>g.Aga<strong>in</strong>, success depends on high permeability. A far better way to degas these coal seamsly<strong>in</strong>g <strong>in</strong> close proximity to each other is to use vertical frac wells.3. Vertical frac wells: Vertical frac wells are ideally suited to highly gassy, deep, lowpermeabilitycoal seams where it takes several years prior to m<strong>in</strong><strong>in</strong>g to adequately degas the coal.These wells are drilled from the surface on a grid pattern over the entire property or only onlongwall panels to <strong>in</strong>tersect the coal seam to be m<strong>in</strong>ed <strong>in</strong> the future.Vertical wells drilled <strong>in</strong>to the coal seam seldom produce measurable amounts of gas withouthydraulic stimulation. High-pressure water (or other fluids) with sand are pumped <strong>in</strong>to the coalseam to create fractures (Figure 6–6). The fluid (water) is then pumped out, but the sandrema<strong>in</strong>s, keep<strong>in</strong>g the fractures open <strong>for</strong> gas to escape to the well bore. Under ideal conditions,if the vertical frac wells are drilled more than 5–10 years <strong>in</strong> advance of m<strong>in</strong><strong>in</strong>g, 60%–70% of themethane <strong>in</strong> the coal seam can be removed prior to m<strong>in</strong><strong>in</strong>g.Vertical frac wells have been very successful <strong>in</strong> the Appalachian and San Juan Coal Bas<strong>in</strong>s of theUnited States. They have also been attempted <strong>in</strong> the United K<strong>in</strong>gdom, Germany, Poland, Ch<strong>in</strong>a,and Australia, but met with only limited success. Major reasons <strong>for</strong> the lack of success abroadare (1) cost and (2) lack of sufficient permeability, which are further expla<strong>in</strong>ed below.1. The cost of drill<strong>in</strong>g and hydrofrac<strong>in</strong>g a well <strong>in</strong> Europe and Australia is typically threetimes the cost <strong>in</strong> the United States. The cost of permitt<strong>in</strong>g and site preparation is alsohigher. In many countries, the drill<strong>in</strong>g and hydrofrac<strong>in</strong>g equipment are not convenientlyavailable.Figure 6–6.—Prem<strong>in</strong><strong>in</strong>g methane dra<strong>in</strong>age from surface.