77CHAPTER 6.—COAL SEAM DEGASIFICATIONBy Pramod C. Thakur, Ph.D. 1In This Chapter Orig<strong>in</strong>s of coalbed methane Reservoir properties of coal seams Thresholds <strong>for</strong> coal seam degasification <strong>Methane</strong> emissions <strong>in</strong> m<strong>in</strong>es <strong>Methane</strong> dra<strong>in</strong>age techniques How to transport gas safely <strong>in</strong> m<strong>in</strong>e pipel<strong>in</strong>esand Economics of coal seam degasificationRecommended publications on coal seam degasificationare Gas <strong>Control</strong> <strong>in</strong> Underground Coal M<strong>in</strong><strong>in</strong>g [Creedy et al.1997], Coalbed <strong>Methane</strong> Extraction [Davidson et al. 1995],and <strong>Methane</strong> <strong>Control</strong> <strong>for</strong> Underground Coal M<strong>in</strong>es[Diamond 1994].ORIGINS OF COALBED METHANE AND RESERVOIR PROPERTIESOF COAL SEAMSOrig<strong>in</strong>s of coalbed methane. Coal seams <strong>for</strong>m over millions of years by the biochemical decayand metamorphic trans<strong>for</strong>mation of plant materials. This coalification process produces largequantities of byproduct gases, such as methane and carbon dioxide. The amount of thesebyproducts <strong>in</strong>creases with the rank of coal. It is the highest <strong>for</strong> anthracite, where <strong>for</strong> every ton ofcoal nearly 1,900 lb of water, 2,420 lb (20,000 ft 3 ) of carbon dioxide, and 1,186 lb (27,000 ft 3 ) ofmethane are produced [Hargraves 1973]. Most of these gases escape to the atmosphere dur<strong>in</strong>gthe coalification process, but a small fraction is reta<strong>in</strong>ed <strong>in</strong> the coal. The amount of gas reta<strong>in</strong>ed<strong>in</strong> the coal depends on a number of factors, such as the rank of coal, the depth of burial, the typeof rock <strong>in</strong> the immediate roof and floor, local geologic anomalies, and the tectonic pressures andtemperatures prevalent at that time. The gases are conta<strong>in</strong>ed under pressure and ma<strong>in</strong>ly adsorbedon the surface of the coal matrix, but a small fraction of gases is also present <strong>in</strong> the fracture networkof the coal. <strong>Methane</strong> is the major component of gases <strong>in</strong> coal, compris<strong>in</strong>g 80%–90% ormore of the total gas volume. The balance is made up of ethane, propane, butane, carbondioxide, hydrogen, oxygen, and argon.1 Manager, Coal Seam Degasification, CONSOL Energy, Inc., Morgantown, WV.

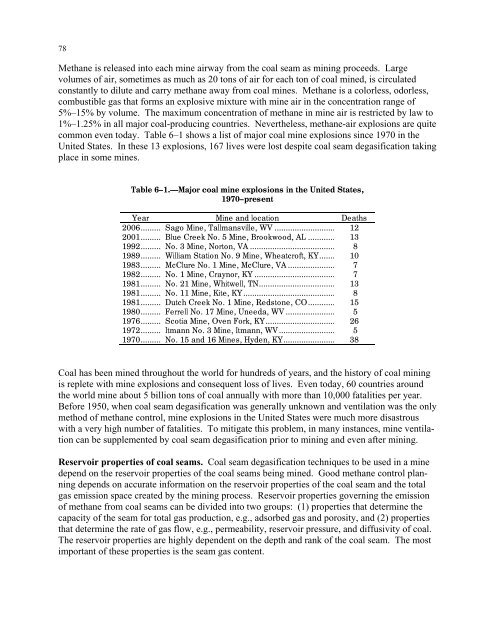

78<strong>Methane</strong> is released <strong>in</strong>to each m<strong>in</strong>e airway from the coal seam as m<strong>in</strong><strong>in</strong>g proceeds. Largevolumes of air, sometimes as much as 20 tons of air <strong>for</strong> each ton of coal m<strong>in</strong>ed, is circulatedconstantly to dilute and carry methane away from coal m<strong>in</strong>es. <strong>Methane</strong> is a colorless, odorless,combustible gas that <strong>for</strong>ms an explosive mixture with m<strong>in</strong>e air <strong>in</strong> the concentration range of5%–15% by volume. The maximum concentration of methane <strong>in</strong> m<strong>in</strong>e air is restricted by law to1%–1.25% <strong>in</strong> all major coal-produc<strong>in</strong>g countries. Nevertheless, methane-air explosions are quitecommon even today. Table 6–1 shows a list of major coal m<strong>in</strong>e explosions s<strong>in</strong>ce 1970 <strong>in</strong> theUnited States. In these 13 explosions, 167 lives were lost despite coal seam degasification tak<strong>in</strong>gplace <strong>in</strong> some m<strong>in</strong>es.Table 6–1.—Major coal m<strong>in</strong>e explosions <strong>in</strong> the United States,1970–presentYear M<strong>in</strong>e and location Deaths2006......... Sago M<strong>in</strong>e, Tallmansville, WV ........................... 122001......... Blue Creek No. 5 M<strong>in</strong>e, Brookwood, AL ............ 131992......... No. 3 M<strong>in</strong>e, Norton, VA ...................................... 81989......... William Station No. 9 M<strong>in</strong>e, Wheatcroft, KY....... 101983......... McClure No. 1 M<strong>in</strong>e, McClure, VA ..................... 71982......... No. 1 M<strong>in</strong>e, Craynor, KY .................................... 71981......... No. 21 M<strong>in</strong>e, Whitwell, TN.................................. 131981......... No. 11 M<strong>in</strong>e, Kite, KY......................................... 81981......... Dutch Creek No. 1 M<strong>in</strong>e, Redstone, CO............ 151980......... Ferrell No. 17 M<strong>in</strong>e, Uneeda, WV ...................... 51976......... Scotia M<strong>in</strong>e, Oven Fork, KY............................... 261972......... Itmann No. 3 M<strong>in</strong>e, Itmann, WV ......................... 51970......... No. 15 and 16 M<strong>in</strong>es, Hyden, KY....................... 38Coal has been m<strong>in</strong>ed throughout the world <strong>for</strong> hundreds of years, and the history of coal m<strong>in</strong><strong>in</strong>gis replete with m<strong>in</strong>e explosions and consequent loss of lives. Even today, 60 countries aroundthe world m<strong>in</strong>e about 5 billion tons of coal annually with more than 10,000 fatalities per year.Be<strong>for</strong>e 1950, when coal seam degasification was generally unknown and ventilation was the onlymethod of methane control, m<strong>in</strong>e explosions <strong>in</strong> the United States were much more disastrouswith a very high number of fatalities. To mitigate this problem, <strong>in</strong> many <strong>in</strong>stances, m<strong>in</strong>e ventilationcan be supplemented by coal seam degasification prior to m<strong>in</strong><strong>in</strong>g and even after m<strong>in</strong><strong>in</strong>g.Reservoir properties of coal seams. Coal seam degasification techniques to be used <strong>in</strong> a m<strong>in</strong>edepend on the reservoir properties of the coal seams be<strong>in</strong>g m<strong>in</strong>ed. Good methane control plann<strong>in</strong>gdepends on accurate <strong>in</strong><strong>for</strong>mation on the reservoir properties of the coal seam and the totalgas emission space created by the m<strong>in</strong><strong>in</strong>g process. Reservoir properties govern<strong>in</strong>g the emissionof methane from coal seams can be divided <strong>in</strong>to two groups: (1) properties that determ<strong>in</strong>e thecapacity of the seam <strong>for</strong> total gas production, e.g., adsorbed gas and porosity, and (2) propertiesthat determ<strong>in</strong>e the rate of gas flow, e.g., permeability, reservoir pressure, and diffusivity of coal.The reservoir properties are highly dependent on the depth and rank of the coal seam. The mostimportant of these properties is the seam gas content.

- Page 1 and 2:

TMIC 9486Information Circular/2006H

- Page 3 and 4:

ORDERING INFORMATIONCopies of Natio

- Page 5 and 6:

ILLUSTRATIONS—ContinuedPage4-6. U

- Page 8:

HANDBOOK FOR METHANE CONTROL IN MIN

- Page 11 and 12:

4Below 5%, called the lower explosi

- Page 13 and 14:

6reduced pressure, except at very l

- Page 15 and 16:

8Static electricity. Protection aga

- Page 17 and 18:

10Figure 1-4.—Estimated methane c

- Page 19 and 20:

12LAYERING OF METHANE AT THE MINE R

- Page 21 and 22:

14good eyesight. 24methane level.Ot

- Page 23 and 24:

16a material balance indicated that

- Page 25 and 26:

18As an example, assume that themet

- Page 27 and 28:

20Figure 1-10.—Relative frequency

- Page 29 and 30:

22Davies AW, Isaac AK, Cook PM [200

- Page 31 and 32: 24Margerson SNA, Robinson H, Wilkin

- Page 33 and 34: CHAPTER 2.—SAMPLING FOR METHANE I

- Page 35 and 36: 29USING PORTABLE METHANE DETECTORST

- Page 37 and 38: Out-of-range gas concentrations in

- Page 39 and 40: Figure 2-3.—Recorder chart from a

- Page 41 and 42: 35Industrial Scientific Corp. [2004

- Page 43 and 44: 38peaks, not the overallmethane lev

- Page 45 and 46: 40hung on J-hook assemblies, which

- Page 47 and 48: 42Methane dilution effectiveness.Th

- Page 49 and 50: 44found that effective scrubber ope

- Page 51 and 52: 46When the scrubber exhaust is not

- Page 53 and 54: 48Methane monitors are usually moun

- Page 55 and 56: 50to use radial bits instead of con

- Page 57 and 58: 52Mott ML, Chuhta EJ [1991]. Face v

- Page 59 and 60: 54Service, Centers for Disease Cont

- Page 61 and 62: 56Methane accumulationsaround thesh

- Page 63 and 64: 58corner and by 43% at supportNo. 4

- Page 65 and 66: 60When using water sprays to reduce

- Page 67 and 68: 62Cecala AB, Zimmer JA, Thimons ED

- Page 69 and 70: 64DESIGNING BLEEDER SYSTEMSAs part

- Page 71 and 72: 66Caved area characteristics. The c

- Page 73 and 74: 68then move this gas into the activ

- Page 75 and 76: 70perform tests to determine whethe

- Page 77 and 78: 72A major purpose of the bleeder sy

- Page 79 and 80: 74• Inlets to the pillared area n

- Page 81: 76REFERENCESCFR. Code of federal re

- Page 85 and 86: 80Figure 6-1.—Gas content of coal

- Page 87 and 88: 82Figure 6-3.—Simplified illustra

- Page 89 and 90: 842. In-mine inclined or vertical b

- Page 91 and 92: 861. Packed cavity method and its v

- Page 93 and 94: 88Table 6-3.—Methane capture rati

- Page 95 and 96: 90Early experiences with this metho

- Page 97 and 98: 9211. At the surface installation (

- Page 99 and 100: 94• Estimated cost for moderately

- Page 101 and 102: 96Thakur PC [1981]. Methane control

- Page 103 and 104: 98Anomalous, unanticipated methane

- Page 105 and 106: 100Vertical methane drainage boreho

- Page 107 and 108: 102Figure 7-2 shows a mine entry ap

- Page 109 and 110: 104obvious solution to this problem

- Page 111 and 112: 106Figure 7-8.—Hypothetical gas c

- Page 113 and 114: 108Lama and Bodziony [1998] compile

- Page 115 and 116: 110In-mine methane drainage systems

- Page 117 and 118: 112Iannacchione AT, Ulery JP, Hyman

- Page 119 and 120: 114More sophisticated reservoir eng

- Page 121 and 122: 116coal lithotype on gas content is

- Page 123 and 124: 118FORECASTING REMAINING GAS-IN-PLA

- Page 125 and 126: 120⎛ y⎞⎜⎛⎞ ⎛ ⎞= ⎜

- Page 127 and 128: 122emissions. The geometry and size

- Page 129 and 130: 124Reservoir models require a subst

- Page 131 and 132: 126King GR, Ertekin T [1989a]. A su

- Page 133 and 134:

128an area of 314 ft 2 would requir

- Page 135 and 136:

130In the case of the abovementione

- Page 137 and 138:

132FILLING SHAFTS AT CLOSED MINESFi

- Page 139 and 140:

134Hinderfeld G [1995]. Ventilation

- Page 141 and 142:

136To calculate the effectiveinert,

- Page 143 and 144:

138exhaust. The remaining diesel ex

- Page 145 and 146:

140required only 4 min. As a result

- Page 147 and 148:

142Figure 11-1.—Desorption test a

- Page 149 and 150:

144enclosed in a tunnel-like struct

- Page 151 and 152:

146Kolada RJ [1985]. Investigation

- Page 153 and 154:

148air in a 6-ft by 9-ft by 6.5-ft

- Page 155 and 156:

150represents flammable mixtures. F

- Page 157 and 158:

152• In Eastern Europe, petroleum

- Page 159 and 160:

154Category II applies to domal sal

- Page 161 and 162:

1562. Monitoring for gas and taking

- Page 163 and 164:

158These mines typically have large

- Page 165 and 166:

160Dave Graham is the safety and he

- Page 167 and 168:

162Figure 13-2.—Examples of metha

- Page 169 and 170:

164REFERENCESAndrews JN [1987]. Nob

- Page 171 and 172:

166APPENDIX A.—ONTARIO OCCUPATION

- Page 174 and 175:

169CHAPTER 14.—PREVENTING METHANE

- Page 176 and 177:

Ways to confirm the presence of gas

- Page 178 and 179:

173The tunnel face is usually venti

- Page 180 and 181:

175Figure 14-5.—TBM ventilation s

- Page 182 and 183:

face. While one of these elements a

- Page 184 and 185:

179ELIMINATING IGNITION SOURCESElec

- Page 186 and 187:

181INDEXAAbnormally gassy faces....

- Page 188 and 189:

183NNatural ventilation, coal silos

- Page 190 and 191:

Delivering on the Nation’s Promis