Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

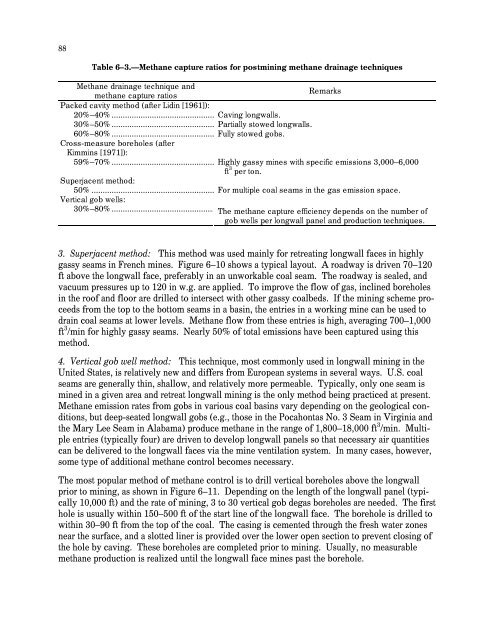

88Table 6–3.—<strong>Methane</strong> capture ratios <strong>for</strong> postm<strong>in</strong><strong>in</strong>g methane dra<strong>in</strong>age techniques<strong>Methane</strong> dra<strong>in</strong>age technique andRemarksmethane capture ratiosPacked cavity method (after Lid<strong>in</strong> [1961]):20%–40% .............................................. Cav<strong>in</strong>g longwalls.30%–50% .............................................. Partially stowed longwalls.60%–80% .............................................. Fully stowed gobs.Cross-measure boreholes (afterKimm<strong>in</strong>s [1971]):59%–70% .............................................. Highly gassy m<strong>in</strong>es with specific emissions 3,000–6,000ft 3 per ton.Superjacent method:50% ....................................................... For multiple coal seams <strong>in</strong> the gas emission space.Vertical gob wells:30%–80% .............................................. The methane capture efficiency depends on the number ofgob wells per longwall panel and production techniques.3. Superjacent method: This method was used ma<strong>in</strong>ly <strong>for</strong> retreat<strong>in</strong>g longwall faces <strong>in</strong> highlygassy seams <strong>in</strong> French m<strong>in</strong>es. Figure 6–10 shows a typical layout. A roadway is driven 70–120ft above the longwall face, preferably <strong>in</strong> an unworkable coal seam. The roadway is sealed, andvacuum pressures up to 120 <strong>in</strong> w.g. are applied. To improve the flow of gas, <strong>in</strong>cl<strong>in</strong>ed boreholes<strong>in</strong> the roof and floor are drilled to <strong>in</strong>tersect with other gassy coalbeds. If the m<strong>in</strong><strong>in</strong>g scheme proceedsfrom the top to the bottom seams <strong>in</strong> a bas<strong>in</strong>, the entries <strong>in</strong> a work<strong>in</strong>g m<strong>in</strong>e can be used todra<strong>in</strong> coal seams at lower levels. <strong>Methane</strong> flow from these entries is high, averag<strong>in</strong>g 700–1,000ft 3 /m<strong>in</strong> <strong>for</strong> highly gassy seams. Nearly 50% of total emissions have been captured us<strong>in</strong>g thismethod.4. Vertical gob well method: This technique, most commonly used <strong>in</strong> longwall m<strong>in</strong><strong>in</strong>g <strong>in</strong> theUnited States, is relatively new and differs from European systems <strong>in</strong> several ways. U.S. coalseams are generally th<strong>in</strong>, shallow, and relatively more permeable. Typically, only one seam ism<strong>in</strong>ed <strong>in</strong> a given area and retreat longwall m<strong>in</strong><strong>in</strong>g is the only method be<strong>in</strong>g practiced at present.<strong>Methane</strong> emission rates from gobs <strong>in</strong> various coal bas<strong>in</strong>s vary depend<strong>in</strong>g on the geological conditions,but deep-seated longwall gobs (e.g., those <strong>in</strong> the Pocahontas No. 3 Seam <strong>in</strong> Virg<strong>in</strong>ia andthe Mary Lee Seam <strong>in</strong> Alabama) produce methane <strong>in</strong> the range of 1,800–18,000 ft 3 /m<strong>in</strong>. Multipleentries (typically four) are driven to develop longwall panels so that necessary air quantitiescan be delivered to the longwall faces via the m<strong>in</strong>e ventilation system. In many cases, however,some type of additional methane control becomes necessary.The most popular method of methane control is to drill vertical boreholes above the longwallprior to m<strong>in</strong><strong>in</strong>g, as shown <strong>in</strong> Figure 6–11. Depend<strong>in</strong>g on the length of the longwall panel (typically10,000 ft) and the rate of m<strong>in</strong><strong>in</strong>g, 3 to 30 vertical gob degas boreholes are needed. The firsthole is usually with<strong>in</strong> 150–500 ft of the start l<strong>in</strong>e of the longwall face. The borehole is drilled towith<strong>in</strong> 30–90 ft from the top of the coal. The cas<strong>in</strong>g is cemented through the fresh water zonesnear the surface, and a slotted l<strong>in</strong>er is provided over the lower open section to prevent clos<strong>in</strong>g ofthe hole by cav<strong>in</strong>g. These boreholes are completed prior to m<strong>in</strong><strong>in</strong>g. Usually, no measurablemethane production is realized until the longwall face m<strong>in</strong>es past the borehole.