Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

Handbook for Methane Control in Mining - AMMSA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

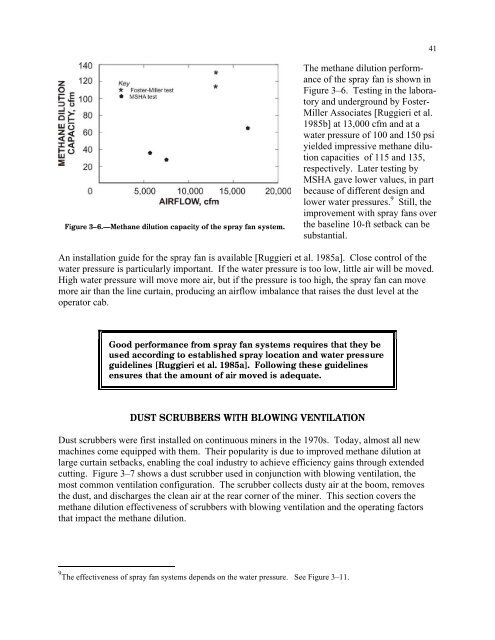

41Figure 3–6.—<strong>Methane</strong> dilution capacity of the spray fan system.The methane dilution per<strong>for</strong>manceof the spray fan is shown <strong>in</strong>Figure 3–6. Test<strong>in</strong>g <strong>in</strong> the laboratoryand underground by Foster-Miller Associates [Ruggieri et al.1985b] at 13,000 cfm and at awater pressure of 100 and 150 psiyielded impressive methane dilutioncapacities of 115 and 135,respectively. Later test<strong>in</strong>g byMSHA gave lower values, <strong>in</strong> partbecause of different design andlower water pressures. 9 Still, theimprovement with spray fans overthe basel<strong>in</strong>e 10-ft setback can besubstantial.An <strong>in</strong>stallation guide <strong>for</strong> the spray fan is available [Ruggieri et al. 1985a]. Close control of thewater pressure is particularly important. If the water pressure is too low, little air will be moved.High water pressure will move more air, but if the pressure is too high, the spray fan can movemore air than the l<strong>in</strong>e curta<strong>in</strong>, produc<strong>in</strong>g an airflow imbalance that raises the dust level at theoperator cab.Good per<strong>for</strong>mance from spray fan systems requires that they beused accord<strong>in</strong>g to established spray location and water pressureguidel<strong>in</strong>es [Ruggieri et al. 1985a]. Follow<strong>in</strong>g these guidel<strong>in</strong>esensures that the amount of air moved is adequate.DUST SCRUBBERS WITH BLOWING VENTILATIONDust scrubbers were first <strong>in</strong>stalled on cont<strong>in</strong>uous m<strong>in</strong>ers <strong>in</strong> the 1970s. Today, almost all newmach<strong>in</strong>es come equipped with them. Their popularity is due to improved methane dilution atlarge curta<strong>in</strong> setbacks, enabl<strong>in</strong>g the coal <strong>in</strong>dustry to achieve efficiency ga<strong>in</strong>s through extendedcutt<strong>in</strong>g. Figure 3–7 shows a dust scrubber used <strong>in</strong> conjunction with blow<strong>in</strong>g ventilation, themost common ventilation configuration. The scrubber collects dusty air at the boom, removesthe dust, and discharges the clean air at the rear corner of the m<strong>in</strong>er. This section covers themethane dilution effectiveness of scrubbers with blow<strong>in</strong>g ventilation and the operat<strong>in</strong>g factorsthat impact the methane dilution.9 The effectiveness of spray fan systems depends on the water pressure. See Figure 3–11.