2007 Interactive Registration Document - Renault

2007 Interactive Registration Document - Renault

2007 Interactive Registration Document - Renault

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

03 ENVIRONMENTAL<br />

SUSTAINABLE DEVELOPMENT<br />

PERFORMANCE<br />

n<br />

n<br />

the automatic gearbox housings are stiffer in order to limit resonance, while<br />

the converter spring has been upgraded to avoid boom at high levels of<br />

engine torque;<br />

the structural response to vibration was improved by adding a rod – similar<br />

to that found on an aircraft wing – to the frame cross-member.<br />

3.2.2.4 WASTE<br />

MANUFACTURING<br />

Since 1995 regular progress has been made in reducing waste volume,<br />

characterizing the types of waste produced and enhancing the reliability of<br />

treatment and recycling processes.<br />

One of the main events in <strong>2007</strong> was the renewal of the contract with waste<br />

management specialist Veolia Propreté Industries Service, at 16 sites in<br />

France. The aim of this contract is to maintain the safety and continuity<br />

of the waste management chain over the long term, from production to<br />

treatment.<br />

In Spain, waste management services have been grouped together, for<br />

improved synergies between the sites of Vallodolid and Palencia, and better<br />

productivity across all Spanish sites.<br />

In Morocco, a global waste management contract was signed in<br />

October <strong>2007</strong>.<br />

Reducing waste volumes ✦<br />

A progress plan has been set up to cut the amount of residual waste sent for<br />

incineration without energy recovery, or sent to landfi ll. To achieve this aim,<br />

the Group is taking action at source (reduction, design, sorting).<br />

The increase in ordinary industrial waste per vehicle produced is mainly due<br />

to the inclusion of new international sites, including Dacia in Romania, RSM in<br />

South Korea, and SOFASA in Colombia. Ordinary waste per vehicle has been<br />

declining since 2002 due to training in sorting at-source and the re-use of<br />

materials.<br />

Partnerships with paint suppliers have made it possible to reduce ordinary waste<br />

such as putty and paint resides. But these reductions have not entirely offset the<br />

increase in hazardous waste caused by the move to water-based paints.<br />

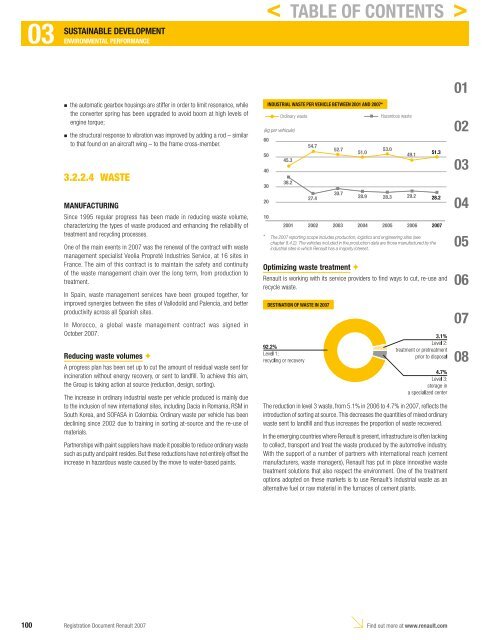

INDUSTRIAL WASTE PER VEHICLE BETWEEN 2001 AND <strong>2007</strong>*<br />

100 <strong>Registration</strong> <strong>Document</strong> <strong>Renault</strong> <strong>2007</strong><br />

Find out more at www.renault.com<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

< TABLE OF CONTENTS ><br />

(kg per vehicule)<br />

Ordinary waste Hazardous waste<br />

45.3<br />

38.2<br />

2001<br />

54.7<br />

27.4<br />

2002<br />

52.7<br />

30.7<br />

2003<br />

51.0<br />

28.9<br />

2004<br />

53.0<br />

28.3<br />

2005<br />

49.1<br />

29.2<br />

2006<br />

* The <strong>2007</strong> reporting scope includes production, logistics and engineering sites (see<br />

c hapter 8.4.2). The vehicles included in the production data are those manufactured by the<br />

industrial sites in which <strong>Renault</strong> has a majority interest.<br />

51.3<br />

28.2<br />

<strong>2007</strong><br />

Optimizing waste treatment ✦<br />

<strong>Renault</strong> is working with its service providers to fi nd ways to cut, re-use and<br />

recycle waste.<br />

DESTINATION OF WASTE IN <strong>2007</strong><br />

The reduction in level 3 waste, from 5.1% in 2006 to 4.7% in <strong>2007</strong>, refl ects the<br />

introduction of sorting at source. This decreases the quantities of mixed ordinary<br />

waste sent to landfi ll and thus increases the proportion of waste recovered.<br />

In the emerging countries where <strong>Renault</strong> is present, infrastructure is often lacking<br />

to collect, transport and treat the waste produced by the automotive industry.<br />

With the support of a number of partners with international reach (cement<br />

manufacturers, waste managers), <strong>Renault</strong> has put in place innovative waste<br />

treatment solutions that also respect the environment. One of the treatment<br />

options adopted on these markets is to use <strong>Renault</strong>’s industrial waste as an<br />

alternative fuel or raw material in the furnaces of cement plants.<br />

01<br />

02<br />

03<br />

04<br />

05<br />

06<br />

07<br />

08