2007 Interactive Registration Document - Renault

2007 Interactive Registration Document - Renault

2007 Interactive Registration Document - Renault

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

03 ENVIRONMENTAL<br />

SUSTAINABLE DEVELOPMENT<br />

PERFORMANCE<br />

3.2.2.1 ENERGY RESOURCES AND CO 2<br />

EMISSIONS<br />

MANUFACTURING<br />

Logistics ✦<br />

Environmental indicators are being progressively integrated in the purchasing<br />

process to see how improvements can be made in the supply and distribution<br />

chain. This includes taking into account the regulatory pollutant emission levels<br />

for vehicles on the road. Greenhouse gas emissions have been lowered by<br />

reducing the amount of fuel used for transportation by optimizing routes, training<br />

personnel in eco-driving, and so on. However, <strong>Renault</strong> wants to collect better<br />

quantitative data by assembling an array of indicators for the various physical<br />

fl ows.<br />

Following the initial measurements of CO 2 emissions declared for 2006,<br />

the logistics department set up a dedicated team to analyze the logistics<br />

performance of <strong>Renault</strong> and its tier-one suppliers. Based on a questionnaire<br />

designed to gather pertinent information, the analysis aims to identify potential<br />

sources of progress that could be turned into action plans for tier-one and tiertwo<br />

suppliers, such as grouping road transport.<br />

The “EPE protocol”, a tool designed to measure the carbon balance, was used to<br />

study and approve changes to transport resources. “Truck+ship” was replaced<br />

by “train+ship” for transporting engines from Valladolid (Spain) to Bursa (Turkey),<br />

or “barge+ship” for parts shipped from the Grand-Couronne site (France) to<br />

assembly plants outside Europe.<br />

Following initiatives to increase the density of transport resources between tierone<br />

suppliers and <strong>Renault</strong> in <strong>2007</strong>, the truck fi ll rate rose from 69% to 74% in<br />

Europe, and the fi ll rate of sea containers from 59 m 3 to 62 m 3 worldwide.<br />

At end-<strong>2007</strong>, <strong>Renault</strong> decided to appoint an environmental manager to<br />

implement global management of the logistics function.<br />

Energy consumption ✦<br />

The action plan originally set in train in 2002 after the inclusion of several new<br />

industrial plants, such as Pitesti (Romania), in the reporting scope has now been<br />

extended. This has resulted in a 12.4% reduction in energy consumption per<br />

vehicle between 2002 and <strong>2007</strong>. This plan comprises two main strands:<br />

Energy saving initiatives<br />

These initiatives rely on rigorous, standardized management of non-production<br />

time and on the convergence of best practices in facility design and control.<br />

This involves:<br />

n<br />

n<br />

n<br />

developing new energy-saving regulation systems;<br />

lighting and heating smaller areas selectively, depending on periods of activity,<br />

or using speed regulation systems for processes with sharply fl uctuating<br />

energy demand;<br />

reducing demand for compressed air, especially during machining<br />

operations;<br />

searching continually for less energy-hungry products, such as lowtemperature<br />

treatment baths and paints that are less sensitive to temperature<br />

and humidity conditions;<br />

developing energy recovery techniques such as recycling calories from<br />

discharged air in paint shops;<br />

boosting boiler output during renewal campaigns;<br />

capturing atmospheric pollutants as close as possible to source in order to<br />

reduce air renewal rates in buildings.<br />

Using renewable energies<br />

The fi rst phase is a detailed study on the timeliness of using renewable energies<br />

(wind, solar thermal and solar photovoltaics, biomass, geothermal and fuel cells)<br />

and their integration in the production process based on study results. The<br />

second phase involves implementation at the most favorable sites:<br />

the fi rst pilot applications of solar thermal energy were set up in <strong>2007</strong> at<br />

the sites of Palencia and Valladolid Motores (Spain) and Cacia (Portugal).<br />

These installations, designed to produce hot water, will make it possible to<br />

shut down thermal power plants in summer, saving around 3,000 MWh and<br />

avoiding some 600 tons of CO 2 every year;<br />

the decision-making process is under way for projects using biomass and<br />

wind power.<br />

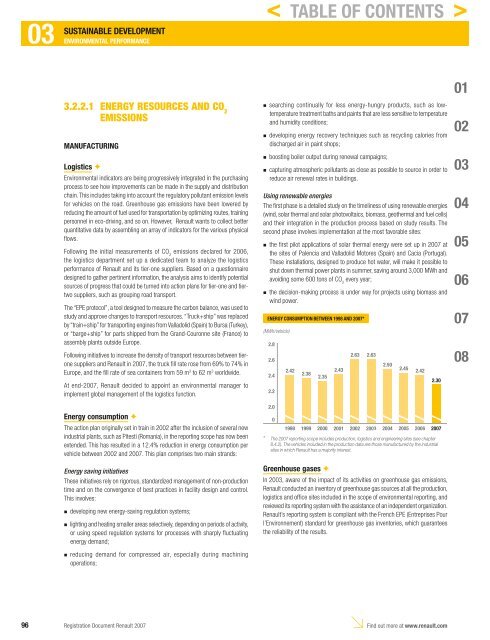

ENERGY CONSUMPTION BETWEEN 1998 AND <strong>2007</strong>*<br />

* The <strong>2007</strong> reporting scope includes production, logistics and engineering sites (see c hapter<br />

8.4.2). The vehicles included in the production data are those manufactured by the industrial<br />

sites in which <strong>Renault</strong> has a majority interest.<br />

Greenhouse gases ✦<br />

In 2003, aware of the impact of its activities on greenhouse gas emissions,<br />

<strong>Renault</strong> conducted an inventory of greenhouse gas sources at all the production,<br />

logistics and offi ce sites included in the scope of environmental reporting, and<br />

reviewed its reporting system with the assistance of an independent organization.<br />

<strong>Renault</strong>’s reporting system is compliant with the French EPE (Entreprises Pour<br />

l’Environnement) standard for greenhouse gas inventories, which guarantees<br />

the reliability of the results.<br />

96 <strong>Registration</strong> <strong>Document</strong> <strong>Renault</strong> <strong>2007</strong><br />

Find out more at www.renault.com<br />

n<br />

n<br />

n<br />

n<br />

n<br />

n<br />

< TABLE OF CONTENTS ><br />

01<br />

02<br />

03<br />

04<br />

05<br />

06<br />

07<br />

08