2007 Interactive Registration Document - Renault

2007 Interactive Registration Document - Renault

2007 Interactive Registration Document - Renault

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

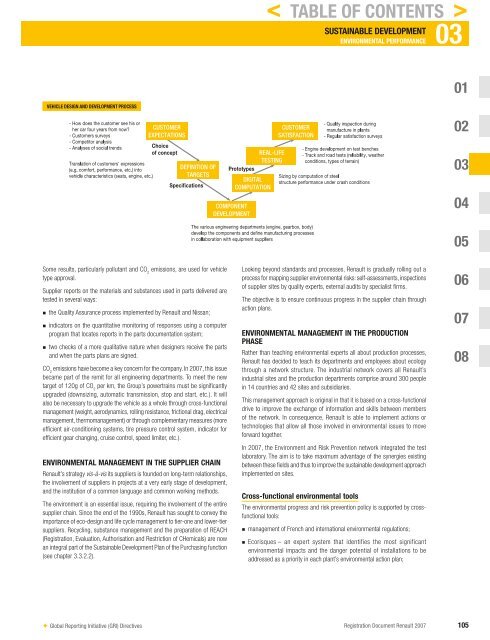

VEHICLE DESIGN AND DEVELOPMENT PROCESS<br />

Some results, particularly pollutant and CO 2 emissions, are used for vehicle<br />

type approval.<br />

Supplier reports on the materials and substances used in parts delivered are<br />

tested in several ways:<br />

n<br />

n<br />

n<br />

the Quality Assurance process implemented by <strong>Renault</strong> and Nissan;<br />

indicators on the quantitative monitoring of responses using a computer<br />

program that locates reports in the parts documentation system;<br />

two checks of a more qualitative nature when designers receive the parts<br />

and when the parts plans are signed.<br />

CO 2 emissions have become a key concern for the company. In <strong>2007</strong>, this issue<br />

became part of the remit for all engineering departments. To meet the new<br />

target of 120g of CO 2 per km, the Group’s powertrains must be signifi cantly<br />

upgraded (downsizing, automatic transmission, stop and start, etc.). It will<br />

also be necessary to upgrade the vehicle as a whole through cross-functional<br />

management (weight, aerodynamics, rolling resistance, frictional drag, electrical<br />

management, thermomanagement) or through complementary measures (more<br />

effi cient air-conditioning systems, tire pressure control system, indicator for<br />

effi cient gear changing, cruise control, speed limiter, etc.).<br />

ENVIRONMENTAL MANAGEMENT IN THE SUPPLIER CHAIN<br />

<strong>Renault</strong>’s strategy vis-à-vis its suppliers is founded on long-term relationships,<br />

the involvement of suppliers in projects at a very early stage of development,<br />

and the institution of a common language and common working methods.<br />

The environment is an essential issue, requiring the involvement of the entire<br />

supplier chain. Since the end of the 1990s, <strong>Renault</strong> has sought to convey the<br />

importance of eco-design and life cycle management to tier-one and lower-tier<br />

suppliers. Recycling, substance management and the preparation of REACH<br />

(<strong>Registration</strong>, Evaluation, Authorisation and Restriction of CHemicals) are now<br />

an integral part of the Sustainable Development Plan of the Purchasing function<br />

(see c hapter 3.3.2.2).<br />

✦ Global Reporting Initiative (GRI) Directives<br />

SUSTAINABLE DEVELOPMENT 03<br />

ENVIRONMENTAL PERFORMANCE<br />

Looking beyond standards and processes, <strong>Renault</strong> is gradually rolling out a<br />

process for mapping supplier environmental risks: self-assessments, inspections<br />

of supplier sites by quality experts, external audits by specialist fi rms.<br />

The objective is to ensure continuous progress in the supplier chain through<br />

action plans.<br />

ENVIRONMENTAL MANAGEMENT IN THE PRODUCTION<br />

PHASE<br />

Rather than teaching environmental experts all about production processes,<br />

<strong>Renault</strong> has decided to teach its departments and employees about ecology<br />

through a network structure. The industrial network covers all <strong>Renault</strong>’s<br />

industrial sites and the production departments comprise around 300 people<br />

in 14 countries and 42 sites and subsidiaries.<br />

This management approach is original in that it is based on a cross-functional<br />

drive to improve the exchange of information and skills between members<br />

of the network. In consequence, <strong>Renault</strong> is able to implement actions or<br />

technologies that allow all those involved in environmental issues to move<br />

forward together.<br />

In <strong>2007</strong>, the Environment and Risk Prevention network integrated the test<br />

laboratory. The aim is to take maximum advantage of the synergies existing<br />

between these fi elds and thus to improve the sustainable development approach<br />

implemented on sites.<br />

Cross-functional environmental tools<br />

The environmental progress and risk prevention policy is supported by crossfunctional<br />

tools:<br />

n<br />

n<br />

< TABLE OF CONTENTS ><br />

management of French and international environmental regulations;<br />

Ecorisques – an expert system that identifies the most significant<br />

environmental impacts and the danger potential of installations to be<br />

addressed as a priority in each plant’s environmental action plan;<br />

01<br />

02<br />

03<br />

04<br />

05<br />

06<br />

07<br />

08<br />

<strong>Registration</strong> <strong>Document</strong> <strong>Renault</strong> <strong>2007</strong> 105