1938 Cadillac V16 - GM Heritage Center

1938 Cadillac V16 - GM Heritage Center

1938 Cadillac V16 - GM Heritage Center

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Cadillac</strong>-LaSalle Preliminary Service Information 9<br />

Engine<br />

38-50 38-60 & 6$ 38-75<br />

Bore and stroke 3¾ x 4½" 3½ x 4½" 3½ x 4½"<br />

Piston displacement 322 cu. in. 346 cu. in. 346 cu. in.<br />

Taxable H. P 36.45 39.20 39.20<br />

Compression ratio 6.25 to 1 6.25 to 1 6.70 to 1<br />

V-8 Engines<br />

The 38-series V-8 engines incorporate a number<br />

of refinements but are otherwise unchanged from<br />

the corresponding previous series. There have<br />

been no changes in engine sizes, but the power<br />

output of the 38-75 engine only has been increased<br />

by raising the compression ratio from 6.25 to<br />

6.70. The 38-75 engine will therefore require the<br />

use of ethylized or other high octane fuel.<br />

This change in compression ratio does not<br />

seriously affect parts stock requirements, as the<br />

higher ratio on 38-75 is secured by using the same<br />

cylinder head as used on 38-50 engines. The<br />

markings on production cylinder heads must be<br />

understood, however, to avoid confusion. They<br />

are as follows:<br />

Right-hand cylinder heads on both 38-50 and<br />

38-75 engines are marked *322-625 and 346-680,<br />

whereas left-hand cylinder heads on 38-50 arc<br />

marked 322-625 and on 38-75 are marked 346-680.<br />

Cylinder heads supplied by the Parts Division,<br />

however, will be marked with both ratios regardless<br />

of whether they are right or left hand heads.<br />

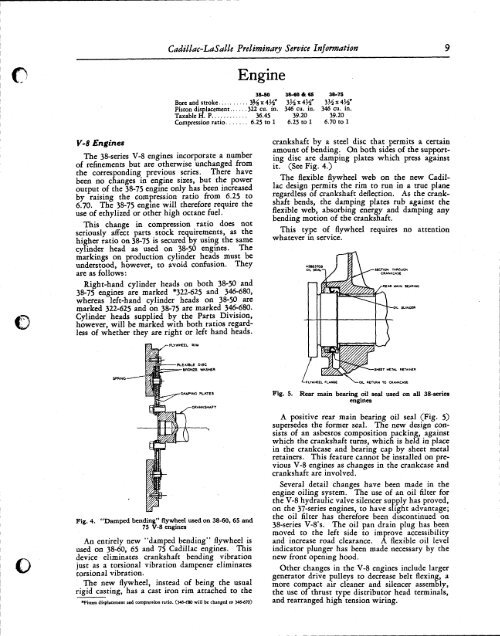

crankshaft by a steel disc that permits a certain<br />

amount of bending. On both sides of the supporting<br />

disc are damping plates which press against<br />

it. (See Fig. 4.)<br />

The flexible flywheel web on the new <strong>Cadillac</strong><br />

design permits the rim to run in a true plane<br />

regardless of crankshaft deflection. As the crankshaft<br />

bends, the damping plates rub against the<br />

flexible web, absorbing energy and damping any<br />

bending motion of the crankshaft.<br />

This type of flywheel requires no attention<br />

whatever in service.<br />

Fig. 5.<br />

Rear main bearing oil seal used on all 38-series<br />

engines<br />

Fig. 4. "Damped bending" flywheel used on 38-60, 65 and<br />

75 V-8 engines<br />

An entirely new "damped bending" flywheel is<br />

used on 38-60, 65 and 75 <strong>Cadillac</strong> engines. This<br />

device eliminates crankshaft bending vibration<br />

just as a torsional vibration dampener eliminates<br />

torsional vibration.<br />

The new flywheel, instead of being the usual<br />

rigid casting, has a cast iron rim attached to the<br />

•Piston displacement and compression ratio. (346-C80 will be changed to 346-670)<br />

A positive rear main bearing oil seal (Fig. 5)<br />

supersedes the former seal. The new design consists<br />

of an asbestos composition packing, against<br />

which the crankshaft turns, which is held in place<br />

in the crankcase and bearing cap by sheet metal<br />

retainers. This feature cannot be installed on previous<br />

V-8 engines as changes in the crankcase and<br />

crankshaft are involved.<br />

Several detail changes have been made in the<br />

engine oiling system. The use of an oil filter for<br />

the V-8 hydraulic valve silencer supply has proved,<br />

on the 37-series engines, to have slight advantage;<br />

the oil filter has therefore been discontinued on<br />

38-series V-8's. The oil pan drain plug has been<br />

moved to the left side to improve accessibility<br />

and increase road clearance. A flexible oil level<br />

indicator plunger has been made necessary by the<br />

new front opening hood.<br />

Other changes in the V-8 engines include larger<br />

generator drive pulleys to decrease belt flexing, a<br />

more compact air cleaner and silencer assembly,<br />

the use of thrust type distributor head terminals,<br />

and rearranged high tension wiring.