- Page 1 and 2:

.iijHjHHHHHI O The 135° V-type Six

- Page 3 and 4:

Advantages of Sixteen Cylinders Six

- Page 5 and 6:

size and increasing fuel economy. T

- Page 7 and 8:

placing these short engines well in

- Page 10 and 11:

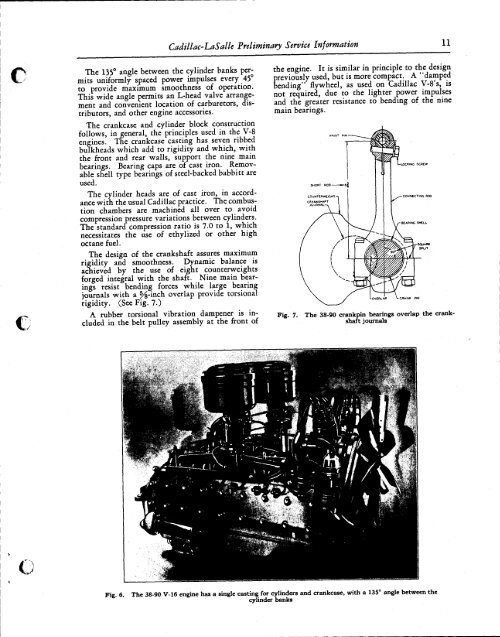

The nine main bearings assure resis

- Page 12 and 13:

LUBRICATION SYSTEM 1 Engine lubrica

- Page 14 and 15:

conical spring at the bottom of eac

- Page 16 and 17:

cylinders of a bank draw from the s

- Page 18 and 19:

more of the radiator is covered by

- Page 20 and 21:

clutch. No spring dampeners are req

- Page 22 and 23:

This has been accomplished by using

- Page 24 and 25:

- In cars using the conventional fr

- Page 26 and 27:

are used for durability. Drums are

- Page 29 and 30:

Copyright 1937 by GENERAL MOTORS SA

- Page 31 and 32:

Right Gasoline The Cadillac V-16 en

- Page 33 and 34:

nstruments and Ltontrols Comfort an

- Page 35 and 36:

Lighting Controls the hand control

- Page 37 and 38:

Starting the Engine Automatic featu

- Page 39 and 40:

Authorized Service Stations Tire an

- Page 41 and 42:

Starting the Car Stopping the Car S

- Page 43 and 44:

Mountain Driving Touring In going u

- Page 45 and 46:

Gasoline Economy Tire Life The numb

- Page 47 and 48:

the owner must estimate the lowest

- Page 49 and 50:

Lubrication Schedule Every 1000 mil

- Page 51 and 52:

new plugs if the old plugs are badl

- Page 53 and 54:

Whenever anti-freeze is to be insta

- Page 55 and 56:

Electrical Storage Battery—The St

- Page 57:

LUBRICATION Check engine oil level

- Page 60 and 61:

CADILLAC- LA DATA SALLE BOOK SEPTEM

- Page 62 and 63:

INDEX TO CONTENTS—Continued Safet

- Page 64 and 65:

A N D L A SALLES FOR 1938 the Great

- Page 66 and 67:

V- EIGHT Cadillac Built The front c

- Page 68 and 69:

T H E N E W SIXTY SPECIAL First to

- Page 70 and 71:

V-EIGHT Roomier and More Luxurious

- Page 72 and 73:

FLEETWOOD New* Proof That The Fine

- Page 74 and 75:

SIXTEEN Standard of the World The r

- Page 76 and 77:

Pistons are likewise graded into 30

- Page 78 and 79:

GENERAL MOTORS CORPORATION Bulwark

- Page 80 and 81:

The unsurpassed degree of Cadillac'

- Page 82 and 83:

and three large bearings of the V-8

- Page 84 and 85:

much shorter and more compact. Give

- Page 86 and 87:

about half the corresponding distan

- Page 88 and 89:

lubrication is assured, regardless

- Page 90 and 91:

^^^^^^^^^^^^^ ••ill The La Sall

- Page 92 and 93:

and LaSalle, provide their exceedin

- Page 94 and 95:

and a rebound cushion. The compress

- Page 96 and 97:

which increases its power output to

- Page 98 and 99:

is essential to prevent piston-to-b

- Page 100 and 101:

automobile. For further Cadillac re

- Page 102 and 103:

Zero Clearance • — S 0 -HJ»?==

- Page 104 and 105:

F U E L SYSTEM Fuel Pump Fuel is fe

- Page 106 and 107:

simple and positive in operation an

- Page 108 and 109:

order, and the other supplies those

- Page 110 and 111:

expansion chamber in the exhaust pi

- Page 112 and 113:

keeps the battery at its peak load

- Page 114 and 115:

power Parking Lights. Headlamp beam

- Page 116 and 117:

Thermostatically controlled radiato

- Page 118 and 119:

Additional piping, common in other

- Page 120 and 121:

LUBRICATION Engine Lubrication SYST

- Page 122 and 123:

portant Cadillac feature is not fou

- Page 124 and 125:

The clutch throwout bearing has a s

- Page 126 and 127:

New, More Durable Transmission Engi

- Page 128 and 129:

The New LaSalle Chassis

- Page 130 and 131:

Front X-members are riveted to the

- Page 133 and 134:

within the car as it is driven over

- Page 135 and 136:

LaSalle and Cadillac Sixty, while t

- Page 137 and 138:

outside the frame side bar because

- Page 139 and 140:

Double Ride Stabilizers Ride stabil

- Page 141 and 142:

Springs are rigidly attached at the

- Page 143 and 144:

ing surface of cast iron moulded to

- Page 145 and 146:

On some cars the hand brake acts up

- Page 147 and 148:

The differential housing is cylindr

- Page 149 and 150:

L A SALLE P E R F O R M A N C E The

- Page 151 and 152:

Higher, wider fender catwalks also

- Page 153 and 154:

exposed chrome plated hinges and a

- Page 155 and 156:

in a new neutral shade which matche

- Page 157 and 158:

down the tonneau side. The padded p

- Page 159:

The center panel is an expensive mo

- Page 163 and 164:

INSULATION LaSalle's Steel Body is

- Page 165 and 166:

Running boards are separated from t

- Page 167 and 168:

PI < 5 m D LASALLE Interior Dimensi

- Page 169 and 170:

CADILLAC SIXTY A P P E A R A N C E

- Page 171 and 172:

On each panel are three groups of l

- Page 173 and 174:

The Sixty has the new smooth instru

- Page 175 and 176:

of these is the construction and mo

- Page 177 and 178:

into an area heretofore restricted.

- Page 179 and 180:

thickly padded center arm rest has

- Page 181 and 182:

C A D I L L A C SIXTY INTERIOR DIME

- Page 183 and 184:

EXTERIOR APPEARANCE Front View: The

- Page 185 and 186:

streamlined ends, in each of which

- Page 187 and 188:

have high, protruding transmission

- Page 189 and 190:

00 CADILLAC CUSTOM V-8 Interior Dim

- Page 191 and 192:

tion with Fleetwood, thus complemen

- Page 193 and 194:

cumbersomeness so typical of other

- Page 195 and 196:

Running boards are separated from t

- Page 197 and 198:

Looking outward from the new Fleetw

- Page 200 and 201:

CADILLAC FLEETWOOD 5-PASSENGER SEDA

- Page 202 and 203:

CADILLAC FLEETWOOD 5-PASSENGER TOWN

- Page 204:

CADILLAC FLEETWOOD 5-PASSENGER SEDA

- Page 208:

CADILLAC FLEETWOOD 7-PASSENGER IMPE

- Page 211 and 212:

220f—

- Page 213 and 214:

FRONT SEAT MOVES 4" FROM REAR POSIT

- Page 215 and 216:

fRONT SEAT MOVES 4" FROM REAR POSIT

- Page 218 and 219:

CADILLAC FLEETWOOD CONVERTIBLE COUP

- Page 220:

CADILLAC FLEETWOOD CONVERTIBLE SEDA

- Page 223 and 224:

CADILLAC SIXTEEN Establishes a New

- Page 225 and 226:

SIXTEEN EXTERIOR STYLING The new Ca

- Page 227 and 228:

CADILLAC SIXTEEN INTERIORS Fleetwoo

- Page 229 and 230:

Garnish mouldings and paneling are

- Page 231 and 232:

CADILLAC 5-PASSENGER STYLE NO. 9019

- Page 233:

CADILLAC SIXTEEN 5-PASSENGER TOWN S

- Page 237:

CADILLAC SIXTEEN 7-PASSENGER SEDAN

- Page 241:

CADILLAC SIXTEEN 5-PASSENGER FORMAL

- Page 244 and 245:

FRONT SEAT MOVES 4" FROM REAR POSIT

- Page 247 and 248:

CADILLAC SIXTEEN 5-PASSENGER COUPE

- Page 249:

CADILLAC SIXTEEN CONVERTIBLE COUPE

- Page 253:

CADILLAC SIXTEEN TOWN CAR STYLE NO.

- Page 256 and 257:

Advantages of Sixteen Cylinders Six

- Page 258 and 259:

size and increasing fuel economy. T

- Page 260 and 261:

placing these short engines well in

- Page 262 and 263:

v Engine Mounting The engine is sup

- Page 264 and 265:

X necting rods. Two grooves inside

- Page 266 and 267:

with the previously mentioned main

- Page 268 and 269:

frame crossmember to the left hand

- Page 270 and 271: N From each pump water is forced di

- Page 272 and 273: the generator and its driving wheel

- Page 274 and 275: SIXTEEN CHASSIS To complement its s

- Page 276 and 277: proves roadability by reducing roll

- Page 278 and 279: Three point manual adjustment is pr

- Page 280 and 281: welded into position to increase ho

- Page 282 and 283: SERVICE AS A SALES AID The high sta

- Page 284 and 285: NEW SERVICE CONTRACT The Cadillac-L

- Page 286 and 287: CADILLAC-LaSALLE Exclusive Accessor

- Page 288 and 289: CADILLAC STANDARD RADIO The 1938 mo

- Page 290 and 291: ADVERSE WEATHER LIGHTS Cadillac Fog

- Page 292 and 293: REAR COMPARTMENT HOT WATER HEATER T

- Page 294 and 295: SEAT COVERS Cadillac Sea-Breeze Sea

- Page 296 and 297: MAJOR POINTS OF COMPARISON-Confd Ca

- Page 298 and 299: DETAILED SPECIFICATIONS ENGINE LaSa

- Page 300 and 301: DETAILED SPECIFICATIONS-Cont'd TIMI

- Page 302 and 303: FUEL—Cont'd Carburetor type Up or

- Page 304 and 305: GENERATOR—Cont'd Generator normal

- Page 306 and 307: REAR AXLE—-Cont'd LaSalle Minimum

- Page 308 and 309: DETAILED SPECIFICATIONS-ContV* BRAK

- Page 310 and 311: DETAILED SPECIFICATIONS-Confd BEARI

- Page 312 and 313: Copyright 1937 by GENERAL MOTORS SA

- Page 314 and 315: The 38-series Cadillac-LaSalle cars

- Page 316 and 317: 6 Cadillac-LaSalle Preliminary Serv

- Page 318 and 319: 8 Cadillac-LaSaile Preliminary Serv

- Page 322 and 323: 12 Cadillac-LaSalle Preliminary Ser

- Page 324 and 325: 14 Cadillac-LaSalle Preliminary Ser

- Page 326 and 327: 16 Cadillac-LaSalle Preliminary Ser

- Page 328 and 329: 18 Cadillac-LaSalle Preliminary Ser

- Page 330 and 331: 20 Cadillac-LaSalle Preliminary Ser

- Page 332 and 333: 22 Cadillac-LaSalle Preliminary Ser

- Page 334 and 335: 24 Cadillac-LaSaile Preliminary Ser

- Page 336 and 337: ? 3 IM Salt* v-8 (38-81) 1M* Styiti

- Page 338 and 339: COLOR COMBINATIONS (Continued) x Co

- Page 340 and 341: COLOR COMBINATION FOR 1938 SERIES C

- Page 342 and 343: B 4-0000 Series 38-50, 60, 60», 65

- Page 344 and 345: Series B6.000 38-50,60, 60$, 65, 7

- Page 346 and 347: B 4.0000 38-50, 60, 60s, 65, 75, 90

- Page 348: 38-9059. 38-9067. PART NO. Genuine