1938 Cadillac V16 - GM Heritage Center

1938 Cadillac V16 - GM Heritage Center

1938 Cadillac V16 - GM Heritage Center

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Cadillac</strong>-LaSalle Preliminary Service Information 15<br />

C<br />

Carburetion and Manifolding.—Gasoline<br />

is drawn forward from the 26 gallon tank through<br />

a single pipe placed in a cool position outside of<br />

the right hand frame sidebar. This pipe branches<br />

near the front of the engine, with one lead passing<br />

directly to the right hand fuel pump and the other<br />

one crossing in front of the frame front crossmember<br />

and then back to the left hand fuel pump.<br />

Heater for<br />

Automatic<br />

Choke<br />

Automatic Choke<br />

Thermostat —<br />

C<br />

The two fuel pumps are of the familiar linkdriven<br />

flexible diaphragm type. The link drives<br />

project inward and engage push rods operated by<br />

eccentrics on the distributor drive shafts, as shown<br />

in Fig. 13. Gasoline filters are an integral part of<br />

the pumps.<br />

A pipe leads from the right hand fuel pump to<br />

the right hand carburetor, and from the left hand<br />

pump to the left hand carburetor, but these lines<br />

are interconnected so that either pump may supply<br />

both carburetors.<br />

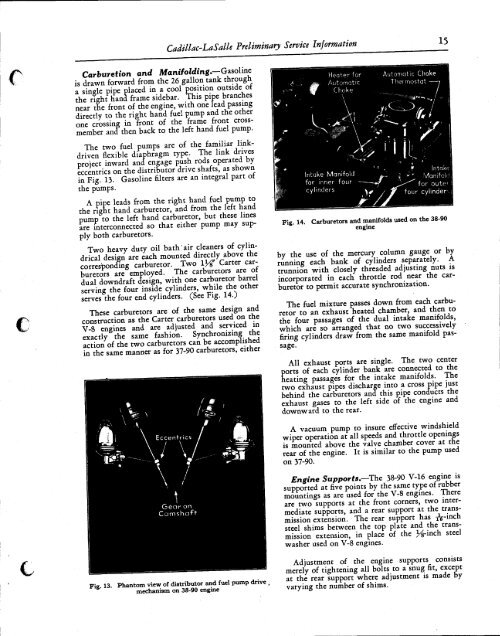

Two heavy duty oil bath "air cleaners of cylindrical<br />

design are each mounted directly above the<br />

corresponding carburetor. Two \Y£ Carter carburetors<br />

are employed. The carburetors are of<br />

dual downdraft design, with one carburetor barrel<br />

serving the four inside cylinders, while the other<br />

serves the four end cylinders. (See Fig. 14.)<br />

These carburetors are of the same design and<br />

construction as the Carter carburetors used on the<br />

V-8 engines and are adjusted and serviced in<br />

exactly the same fashion. Synchronizing the<br />

action of the two carburetors can be accomplished<br />

in the same manner as for 37-90 carburetors, either<br />

Intake Manifold<br />

for inner four<br />

cylinders<br />

» Intake<br />

»" * Manifold<br />

for outer '<br />

four cylinder-,<br />

Fig. 14. Carburetors and manifolds used on the 38-90<br />

engine<br />

by the use of the mercury column gauge or by<br />

running each bank of cylinders separately. A<br />

trunnion with closely threaded adjusting nuts is<br />

incorporated in each throttle rod near the carburetor<br />

to permit accurate synchronization.<br />

The fuel mixture passes down from each carburetor<br />

to an exhaust heated chamber, and then to<br />

the four passages of the dual intake manifolds,<br />

which are so arranged that no two successively<br />

firing cylinders draw from the same manifold passage.<br />

All exhaust ports are single. The two center<br />

Eorts of each cylinder bank are connected to the<br />

eating passages for the intake manifolds. The<br />

two exhaust pipes discharge into a cross pipe just<br />

behind the carburetors and this pipe conducts the<br />

exhaust gases to the left side of the engine and<br />

downward to the rear.<br />

Eccentrics<br />

\ /<br />

Gear on<br />

Camshaft-<br />

^51<br />

A vacuum pump to insure effective windshield<br />

wiper operation at all speeds and throttle openings<br />

is mounted above the valve chamber cover at the<br />

rear of the engine. It is similar to the pump used<br />

on 37-90.<br />

Engine Supports.—The 38-90 V-16 engine is<br />

supported at five points by the same type of rubber<br />

mountings as are used for the V-8 engines. There<br />

are two supports at the front corners, two intermediate<br />

supports, and a rear support at the transmission<br />

extension. The rear support has rV"i 0cn<br />

steel shims between the top plate and the transmission<br />

extension, in place of the )^-inch steel<br />

washer used on V-8 engines.<br />

Fie 13<br />

Phantom view of distributor and fuel pump drive<br />

mechanism on 38-90 engine<br />

Adjustment of the engine supports consists<br />

merely of tightening all bolts to a snug fit, except<br />

at the rear support where adjustment is made by<br />

varying the number of shims.