1938 Cadillac V16 - GM Heritage Center

1938 Cadillac V16 - GM Heritage Center

1938 Cadillac V16 - GM Heritage Center

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

12<br />

<strong>Cadillac</strong>-LaSalle Preliminary Service Information<br />

With the exception of piston pin removal,<br />

service operations are unchanged from previous<br />

practice. Bearing clearance limits are the same as<br />

for V-8 bearings, and the replacement operations<br />

are the same. Piston fitting is performed in the<br />

same manner and with the same feeler gauges as<br />

used for 37-85 and 90. Cylinder reconditioning is<br />

performed in accordance with the instructions for<br />

the V-8 en-block cylinders. Valve service operations<br />

are the same as for V-8, except that it is<br />

necessary to remove the valves before the valve<br />

lifters can be removed.<br />

Piston pins are removed by taking out the locking<br />

screw, then spreading the split end of the<br />

connecting rod with Tool No. J-1167, and tapping<br />

the pin out of piston and rod with a brass drift.<br />

To reinstall a piston pin, first spread the rod with<br />

Tool No. J-H67, then assemble pin in piston and<br />

rod in the correct position, as shown in Fig. 8.<br />

Tap the pin into place and turn the locking screw<br />

part way in before removing the spreading tool.<br />

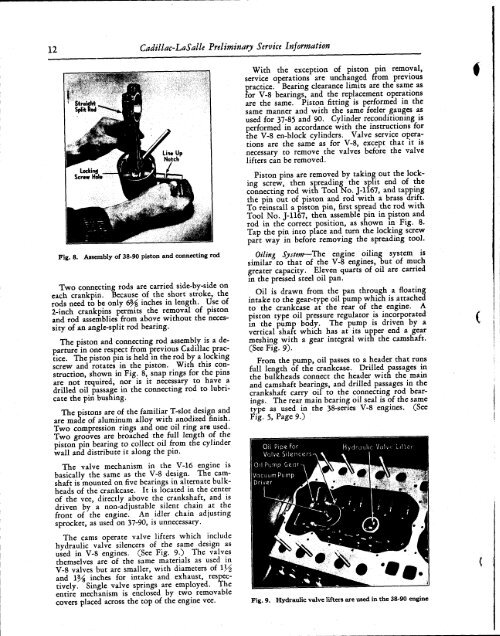

Fig. 8. Assembly of 38-90 piston and connecting rod<br />

Two connecting rods are carried side-by-side on<br />

each crankpin. Because of the short stroke, the<br />

rods need to be only 6% inches in length. Use of<br />

2-inch crankpins permits the removal of piston<br />

and rod assemblies from above without the necessity<br />

of an angle-split rod bearing.<br />

The piston and connecting rod assembly is a departure<br />

in one respect from previous <strong>Cadillac</strong> practice.<br />

The piston pin is held in the rod by a locking<br />

screw and rotates in the piston. With this construction,<br />

shown in Fig. 8, snap rings for the pins<br />

are not required, nor is it necessary to have a<br />

drilled oil passage in the connecting rod to lubricate<br />

the pin bushing.<br />

Thc pistons are of the familiar T-slot design and<br />

are made of aluminum alloy with anodized finish.<br />

Two compression rings and one oil ring are used.<br />

Two grooves are broached the full length of the<br />

piston pin bearing to collect oil from the cylinder<br />

wall and distribute it along the pin.<br />

The valve mechanism in the V-16 engine is<br />

basically the same as the V-8 design. The camshaft<br />

is mounted on five bearings in alternate bulkheads<br />

of the crankcase. It is located in the center<br />

of the vee, directly above the crankshaft, and is<br />

driven by a non-adjustable silent chain at the<br />

front of the engine. An idler chain adjusting<br />

sprocket, as used on 37-90, is unnecessary.<br />

The cams operate valve lifters which include<br />

hydraulic valve silencers of the same design as<br />

used in V-8 engines. (See Fig. 9.) The valves<br />

themselves are of the same materials as used in<br />

V-8 valves but are smaller, with diameters of<br />

and 1¾ inches for intake and exhaust, respectively.<br />

Single valve springs are employed. The<br />

entire mechanism is enclosed by two removable<br />

covers placed across the top of the engine vee.<br />

Oiling System—The engine oiling system is<br />

similar to that of the V-8 engines, but of much<br />

greater capacity. Eleven quarts of oil are carried<br />

in the pressed steel oil pan.<br />

Oil is drawn from the pan through a floating<br />

intake to the gear-type oil pump which is attached<br />

to the crankcase at the rear of the engine. A<br />

piston type oil pressure regulator is incorporated<br />

in the pump body. The pump is driven by a<br />

vertical shaft which has at its upper end a gear<br />

meshing with a gear integral witn the camshaft.<br />

(See Fig. 9).<br />

From the pump, oil passes to a header that runs<br />

full length of the crankcase. Drilled passages in<br />

the bulkheads connect the header with the main<br />

and camshaft bearings, and drilled passages in the<br />

crankshaft carry oil to the connecting rod bearings.<br />

The rear main bearing oil seal is of the same<br />

type as used in the 38-series V-8 engines. (See<br />

Fig. 5, Page 9.)<br />

Fig. 9. Hydraulic valve lifters are used in the 38-90 engine