- Page 1 and 2:

KIRTLAND AIR FORCE BASE ALBUQUERQUE

- Page 3 and 4:

DOCUMENT CERTIFICATION REPORT DOCUM

- Page 5 and 6:

DOCUMENT CERTIFICATION THIS PAGE IN

- Page 7 and 8:

CONTENTS 3.3.7 Groundwater and LNAP

- Page 9 and 10:

FIGURES FIGURES 2-1 Site Location M

- Page 11 and 12:

ACRONYMS AND ABBREVIATIONS ACRONYMS

- Page 13 and 14:

THIS PAGE INTENTIONALLY LEFT BLANK

- Page 15 and 16:

SECTION 1 1.1 Objectives and Scope

- Page 17 and 18:

SECTION 2 2.1 Site Description 2. B

- Page 19 and 20:

SECTION 2 • From roughly 86 ft bg

- Page 21 and 22:

SECTION 2 2.4.2 Investigative Resul

- Page 23 and 24:

SECTION 2 previous sampling results

- Page 25 and 26:

SECTION 2 the soils. Only that part

- Page 27 and 28:

SECTION 2 gpd. Investigating and re

- Page 29 and 30:

SECTION 3 3.2 Quality Assurance/Qua

- Page 31 and 32:

SECTION 3 being both an electrical

- Page 33 and 34:

SECTION 3 3.3.4 Groundwater Monitor

- Page 35 and 36:

SECTION 3 piezometers. Groundwater

- Page 37 and 38:

SECTION 4 association meetings are

- Page 39 and 40:

REFERENCES US Environmental Protect

- Page 41 and 42:

TABLES Table 2-1. Hydrostratigraphi

- Page 43 and 44:

TABLES Table 3-2 Proposed Installat

- Page 45 and 46:

TABLES Installation ID Installation

- Page 47 and 48:

TABLES Installation ID Installation

- Page 49 and 50:

TABLES Installation ID Installation

- Page 51 and 52:

Figures

- Page 53 and 54:

SAN METEO SAN PEDRO 1540886 1541386

- Page 55 and 56:

Source: CH2M HILL 2009 Figure 2-4

- Page 57 and 58:

Source: CH2M HILL 2009 Figure 2-6

- Page 59 and 60:

CONCEPTUAL SITE MODEL Figure 2-8 So

- Page 61 and 62:

SAN METEO SAN PEDRO 1540672 1541172

- Page 63 and 64:

Figure 3‐3 Typical Soil Vapor Mon

- Page 65 and 66:

Appendix A NMED Guidance: NMED TPH

- Page 67 and 68:

A TPH screening guideline was calcu

- Page 69 and 70:

potential indoor air impacts from s

- Page 71 and 72:

Appendix B Project Schedule

- Page 73 and 74:

Appendix C Preliminary Report Outli

- Page 75 and 76:

Appendix D Base-Wide Plans for Inve

- Page 78 and 79:

BASE-WIDE PLAN CONTENTS Section Pag

- Page 80 and 81:

BASE-WIDE PLAN FIGURES Section Page

- Page 82 and 83:

BASE-WIDE PLAN ACRONYMS AFB AFCEE C

- Page 84 and 85:

BASE-WIDE PLAN 1. INTRODUCTION Kirt

- Page 86 and 87:

BASE-WIDE PLAN 2. PROJECT MANAGEMEN

- Page 88 and 89:

BASE-WIDE PLAN Waste Management Pro

- Page 90 and 91:

BASE-WIDE PLAN 3. BASELINE ENVIRONM

- Page 92 and 93:

BASE-WIDE PLAN Figure 3-1. Kirtland

- Page 94 and 95:

BASE-WIDE PLAN Table 3-1. History o

- Page 96 and 97:

BASE-WIDE PLAN Figure 3-2. Location

- Page 98 and 99:

BASE-WIDE PLAN Figure 3-3. Geologic

- Page 100 and 101:

BASE-WIDE PLAN 3.1.3 Hydrogeology D

- Page 102 and 103:

BASE-WIDE PLAN the high nitrate lev

- Page 104 and 105:

BASE-WIDE PLAN Figure 3-4. Extent o

- Page 106 and 107:

BASE-WIDE PLAN REFERENCES Allen, H.

- Page 108 and 109:

APPENDIX A APPENDIX A Field Samplin

- Page 110 and 111:

APPENDIX A CONTENTS Section Page Ta

- Page 112 and 113:

APPENDIX A TABLES Table Page Table

- Page 114 and 115:

APPENDIX A ACRONYMS °C degrees Cel

- Page 116 and 117:

APPENDIX A 1. INTRODUCTION This Bas

- Page 118 and 119:

APPENDIX A 2. FIELD SAMPLING OBJECT

- Page 120 and 121:

APPENDIX A 3. DESIGN OF DATA COLLEC

- Page 122 and 123:

APPENDIX A Table 3-1. Activities As

- Page 124 and 125:

APPENDIX A probability. This techni

- Page 126 and 127:

APPENDIX A 4. SAMPLING EQUIPMENT AN

- Page 128 and 129:

APPENDIX A 4.3.3 Ambient Field Blan

- Page 130 and 131:

APPENDIX A 5. SAMPLE HANDLING AND A

- Page 132 and 133:

APPENDIX A 6. FIELD QA/QC PROGRAM T

- Page 134 and 135:

APPENDIX A 7. SITE MANAGEMENT AND R

- Page 136 and 137:

APPENDIX A The identity of each sam

- Page 138 and 139:

APPENDIX A REFERENCES EPA 1986. RCR

- Page 140 and 141:

APPENDIX B APPENDIX B Standard Oper

- Page 142 and 143:

APPENDIX B CONTENTS Section Page Ta

- Page 144 and 145:

APPENDIX B CONTENTS (Continued) Sec

- Page 146 and 147:

APPENDIX B TABLES Table B4.1-1. Qui

- Page 148 and 149:

APPENDIX B FIGURES Figure B1.1-1. T

- Page 150 and 151:

APPENDIX B ACRONYMS °C degrees Cel

- Page 152 and 153:

APPENDIX B SOP B1.1 Borehole and Sa

- Page 154 and 155:

APPENDIX B Gravely soils are identi

- Page 156 and 157:

APPENDIX B Stratification Stratific

- Page 158 and 159:

APPENDIX B Hardness The hardness of

- Page 160 and 161:

APPENDIX B Igneous rock classificat

- Page 162 and 163:

APPENDIX B Figure B1.1-1. Typical B

- Page 164 and 165:

APPENDIX B Figure B1.1-1. Typical B

- Page 166 and 167:

APPENDIX B Figure B1.1-2. The Unifi

- Page 168 and 169:

APPENDIX B SOP B1.2 Borehole Geophy

- Page 170 and 171:

APPENDIX B Waveforms obtained at ea

- Page 172 and 173:

APPENDIX B The borehole induction s

- Page 174 and 175:

APPENDIX B SOP B1.3 Monitoring Well

- Page 176 and 177:

APPENDIX B finished wells shall als

- Page 178 and 179:

APPENDIX B Figure B1.3-1. Overburde

- Page 180 and 181:

APPENDIX B Figure B1.3-2. Overburde

- Page 182 and 183:

APPENDIX B Figure B1.3-3. Double Ca

- Page 184 and 185:

APPENDIX B Figure B1.3-4. Double Ca

- Page 186 and 187:

APPENDIX B SOP B1.4 Monitoring Well

- Page 188 and 189:

APPENDIX B Chemical application The

- Page 190 and 191:

APPENDIX B Figure B1.4-1. Well Deve

- Page 192 and 193:

APPENDIX B Figure B1.4-1. Well Deve

- Page 194 and 195:

APPENDIX B SOP B1.5 Monitoring Well

- Page 196 and 197:

APPENDIX B Figure B1.5-1. Well Aban

- Page 198 and 199:

APPENDIX B SOP B1.6 Temporary Well-

- Page 200 and 201:

APPENDIX B SOP B1.7 Soil Gas Invest

- Page 202 and 203:

APPENDIX B If instrument blanks ind

- Page 204 and 205:

APPENDIX B SOP B1.8 Surficial Geoph

- Page 206 and 207:

APPENDIX B Relevant notes, remarks

- Page 208 and 209:

APPENDIX B Magnetic Surveys useful

- Page 210 and 211:

APPENDIX B SOP B1.9 Land Surveys A

- Page 212 and 213:

APPENDIX B SOP B1.10 Meteorological

- Page 214 and 215:

APPENDIX B SOP B1.11 Equipment Deco

- Page 216 and 217:

APPENDIX B Personal Protective Equi

- Page 218 and 219:

APPENDIX B SOP B2.1 Sediment Sampli

- Page 220 and 221:

APPENDIX B SOP B2.2 Surface Soil Sa

- Page 222 and 223:

APPENDIX B SOP B2.3 Subsurface Soil

- Page 224 and 225:

APPENDIX B Wear appropriate PPE as

- Page 226 and 227:

APPENDIX B the Classification of Ro

- Page 228 and 229: APPENDIX B Using soil removed from

- Page 230 and 231: APPENDIX B Collect and manage all w

- Page 232 and 233: APPENDIX B SOP B2.4 Test Pit Sampli

- Page 234 and 235: APPENDIX B SOP B2.5 Sample Homogeni

- Page 236 and 237: APPENDIX B SOP B3.1 Photoionization

- Page 238 and 239: APPENDIX B SOP B3.2 Methods for Usi

- Page 240 and 241: APPENDIX B The rate of migration th

- Page 242 and 243: APPENDIX B easily be penetrated wit

- Page 244 and 245: APPENDIX B the identification or qu

- Page 246 and 247: APPENDIX B SOP B3.3 Headspace Scree

- Page 248 and 249: APPENDIX B SOP B4.1 Monitoring Well

- Page 250 and 251: APPENDIX B the drawdown shall not e

- Page 252 and 253: APPENDIX B Sample Collection Once r

- Page 254 and 255: APPENDIX B Figure B4.1-1. Well Purg

- Page 256 and 257: APPENDIX B Table B4.1-1. Quick Conv

- Page 258 and 259: APPENDIX B SOP B4.2 Potable Water S

- Page 260 and 261: APPENDIX B SOP B4.3 Surface Water S

- Page 262 and 263: APPENDIX B SOP B4.4 Field Filtratio

- Page 264 and 265: APPENDIX B SOP B5.1 pH The followin

- Page 266 and 267: APPENDIX B SOP B5.2 Specific Conduc

- Page 268 and 269: APPENDIX B SOP B5.3 Water Temperatu

- Page 270 and 271: APPENDIX B SOP B5.4 Dissolved Oxyge

- Page 272 and 273: APPENDIX B SOP B5.5 Oxidation-Reduc

- Page 274 and 275: APPENDIX B SOP B5.6 Water Levels Wa

- Page 276 and 277: APPENDIX B Figure B5.6-1. Groundwat

- Page 280 and 281: APPENDIX B Packer Testing Procedure

- Page 282 and 283: APPENDIX B All measurements and obs

- Page 284 and 285: APPENDIX B Figure B5.7-1a. Aquifer

- Page 286 and 287: APPENDIX B Figure B5.7-1b. Aquifer

- Page 288 and 289: APPENDIX B Figure B5.7-2. Pump Test

- Page 290 and 291: APPENDIX B SOP B6.1 Drum Sampling F

- Page 292 and 293: APPENDIX B SOP B6.2 Tank Sampling F

- Page 294 and 295: APPENDIX B SOP B6.3 Wipe Sampling T

- Page 296 and 297: APPENDIX B SOP B6.4 Concrete Sampli

- Page 298 and 299: APPENDIX B SOP B6.5 Air Sampling/Ai

- Page 300 and 301: APPENDIX B SOP B7.1 Approved Backgr

- Page 302 and 303: APPENDIX B Table B7.1-1. Approved B

- Page 304 and 305: APPENDIX B Table B7.1-1. Approved B

- Page 306 and 307: APPENDIX B Table B7.1-2. Approved B

- Page 308 and 309: APPENDIX B Table B7.1-3. Approved B

- Page 310 and 311: APPENDIX B Table B7.1-4. Approved B

- Page 312 and 313: APPENDIX B Table B7.1-5. Approved B

- Page 314 and 315: APPENDIX B SOP B7.2 Use of NMED Soi

- Page 316 and 317: APPENDIX B Table B7.2-1. NMED Soil

- Page 318 and 319: APPENDIX B Table B7.2-1. NMED Soil

- Page 320 and 321: APPENDIX B SOP B7.3 Radioactively-C

- Page 322 and 323: APPENDIX B Material used by the Air

- Page 324 and 325: APPENDIX C APPENDIX C Quality Assur

- Page 326 and 327: APPENDIX C CONTENTS Section Page Ta

- Page 328 and 329:

APPENDIX C CONTENTS (Concluded) Sec

- Page 330 and 331:

APPENDIX C TABLES Table Page Table

- Page 332 and 333:

APPENDIX C ACRONYMS AFB AFCEE ASTM

- Page 334 and 335:

APPENDIX C 1. INTRODUCTION This Bas

- Page 336 and 337:

APPENDIX C 2. PROJECT DESCRIPTION 2

- Page 338 and 339:

APPENDIX C 3. PROJECT ORGANIZATION

- Page 340 and 341:

APPENDIX C 2.7 Safety Professional

- Page 342 and 343:

APPENDIX C 4. QUALITY ASSURANCE OBJ

- Page 344 and 345:

APPENDIX C 4.1.4 Accuracy Accuracy

- Page 346 and 347:

APPENDIX C procedures that may resu

- Page 348 and 349:

APPENDIX C 5. FIELD INVESTIGATION P

- Page 350 and 351:

APPENDIX C Table 5-1. Sample Requir

- Page 352 and 353:

APPENDIX C Table 5-2. Sample Requir

- Page 354 and 355:

APPENDIX C 6. SAMPLE CUSTODY AND RE

- Page 356 and 357:

COMP GRAB PRESERVATIVE PRESERVATIVE

- Page 358 and 359:

APPENDIX C sections. The data packa

- Page 360 and 361:

APPENDIX C 7. CALIBRATION PROCEDURE

- Page 362 and 363:

APPENDIX C Geophysical surveying eq

- Page 364 and 365:

APPENDIX C 8. ANALYTICAL PROCEDURES

- Page 366 and 367:

APPENDIX C 9. INTERNAL QUALITY CONT

- Page 368 and 369:

APPENDIX C basis and at a frequency

- Page 370 and 371:

APPENDIX C 10. DATA VALIDATION, RED

- Page 372 and 373:

APPENDIX C Numerical value and unit

- Page 374 and 375:

APPENDIX C 11. PERFORMANCE AND SYST

- Page 376 and 377:

APPENDIX C 12. PREVENTIVE MAINTENAN

- Page 378 and 379:

APPENDIX C 13. DATA ASSESSMENT The

- Page 380 and 381:

APPENDIX C An independent team (ind

- Page 382 and 383:

APPENDIX C 14. CORRECTIVE ACTION Co

- Page 384 and 385:

APPENDIX C Figure 14-1. Nonconforma

- Page 386 and 387:

APPENDIX C 2.44 Data Validation and

- Page 388 and 389:

APPENDIX C 15. QUALITY ASSURANCE RE

- Page 390 and 391:

APPENDIX C Discussion of qualified

- Page 392 and 393:

APPENDIX C REFERENCES Air Force Cen

- Page 394 and 395:

APPENDIX D APPENDIX D Data Manageme

- Page 396 and 397:

APPENDIX D CONTENTS Contents Page T

- Page 398 and 399:

APPENDIX D TABLES Tables Page Table

- Page 400 and 401:

APPENDIX D ACRONYMS AFB AFCEE ASTM

- Page 402 and 403:

APPENDIX D 1. INTRODUCTION 1.1 Purp

- Page 404 and 405:

APPENDIX D 2. DATA QUALITY OBJECTIV

- Page 406 and 407:

APPENDIX D 3. PARTICIPANTS AND RESP

- Page 408 and 409:

APPENDIX D Table 3-1. Participants

- Page 410 and 411:

APPENDIX D 4. DATA MANAGEMENT SYSTE

- Page 412 and 413:

APPENDIX D The purpose of data revi

- Page 414 and 415:

APPENDIX D Compound identification

- Page 416 and 417:

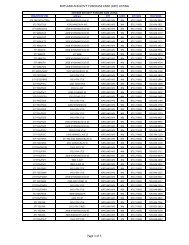

APPENDIX D Sample ID Sample Depth (

- Page 418 and 419:

APPENDIX D LDI SLXI WCI GWD SAMP CA

- Page 420 and 421:

APPENDIX D REFERENCES AFCEE 1993. H

- Page 422 and 423:

APPENDIX E APPENDIX E Waste Managem

- Page 424 and 425:

APPENDIX E CONTENTS Section Page Ta

- Page 426 and 427:

APPENDIX E TABLES Table Page Table

- Page 428 and 429:

APPENDIX E ACRONYMS AFB AOC ACM ARA

- Page 430 and 431:

APPENDIX E 1. INTRODUCTION This doc

- Page 432 and 433:

APPENDIX E Not excluded from regula

- Page 434 and 435:

APPENDIX E ― Maintain or construc

- Page 436 and 437:

APPENDIX E 2. REGULATORY REQUIREMEN

- Page 438 and 439:

APPENDIX E EPA Hazardous Waste Code

- Page 440 and 441:

APPENDIX E 3. WASTE MANAGEMENT CONT

- Page 442 and 443:

APPENDIX E Special wastes (PCS and

- Page 444 and 445:

APPENDIX E hazardous waste will imm

- Page 446 and 447:

APPENDIX E Figure 3-1. Typical Haza

- Page 448 and 449:

APPENDIX E 4. SUMMARY OF EXPECTED I

- Page 450 and 451:

APPENDIX E Table 4-1. Waste Managem

- Page 452 and 453:

APPENDIX E Table 4-1. Waste Managem

- Page 454 and 455:

APPENDIX E Table 4-1. Waste Managem

- Page 456 and 457:

APPENDIX E which allows waste to be

- Page 458 and 459:

APPENDIX E 5. HAZARDOUS WASTE GENER

- Page 460 and 461:

APPENDIX E 5.2.4.3 Radioactive Wast

- Page 462 and 463:

APPENDIX E 5.3.4.1 Special Waste Al

- Page 464 and 465:

APPENDIX E ― Waste profile sheets

- Page 466 and 467:

APPENDIX E copies of manifests from

- Page 468 and 469:

APPENDIX E REFERENCES USAF 1996. Ra

- Page 470 and 471:

APPENDIX F APPENDIX F Base-wide Hea

- Page 472 and 473:

APPENDIX F CONTENTS Table Page Acro

- Page 474 and 475:

APPENDIX F CONTENTS (Concluded) Sec

- Page 476 and 477:

APPENDIX F ACRONYMS ACGIH AFB AHA A

- Page 478 and 479:

APPENDIX F 1. INTRODUCTION 1.1 Purp

- Page 480 and 481:

APPENDIX F 2. PROJECT ORGANIZATION

- Page 482 and 483:

APPENDIX F Ensure that Contractor e

- Page 484 and 485:

APPENDIX F Provide updated document

- Page 486 and 487:

APPENDIX F 3. SITE HISTORY AND DESC

- Page 488 and 489:

APPENDIX F 4. POTENTIAL HAZARDS The

- Page 490 and 491:

APPENDIX F symptoms of heat stress,

- Page 492 and 493:

APPENDIX F irrational or stuporous

- Page 494 and 495:

APPENDIX F pounds. Objects heavier

- Page 496 and 497:

APPENDIX F All circuit breaker pane

- Page 498 and 499:

APPENDIX F SHSS will identify these

- Page 500 and 501:

APPENDIX F When using a hammer wear

- Page 502 and 503:

APPENDIX F All unattended boreholes

- Page 504 and 505:

APPENDIX F Minimize shock loading o

- Page 506 and 507:

APPENDIX F Apply an adequate amount

- Page 508 and 509:

APPENDIX F All personnel involved i

- Page 510 and 511:

APPENDIX F To avoid battery explosi

- Page 512 and 513:

APPENDIX F distances that heavier e

- Page 514 and 515:

APPENDIX F as discussed here refer

- Page 516 and 517:

APPENDIX F 5. ACTIVITY HAZARD ANALY

- Page 518 and 519:

APPENDIX F 6. PERSONAL PROTECTIVE E

- Page 520 and 521:

APPENDIX F Coveralls (outer), chemi

- Page 522 and 523:

APPENDIX F 7. AIR, NOISE, AND OTHER

- Page 524 and 525:

APPENDIX F 8. SITE CONTROL The PM,

- Page 526 and 527:

APPENDIX F 8.2.3 Equipment Decontam

- Page 528 and 529:

APPENDIX F 9. MEDICAL SURVEILLANCE

- Page 530 and 531:

APPENDIX F 10. SAFETY CONSIDERATION

- Page 532 and 533:

APPENDIX F 10.2.2 Housekeeping Clea

- Page 534 and 535:

APPENDIX F Shut off and bleed down

- Page 536 and 537:

APPENDIX F Protect your hands and f

- Page 538 and 539:

APPENDIX F 10.2.16 Electricity Keep

- Page 540 and 541:

APPENDIX F 11. DISPOSAL PROCEDURES

- Page 542 and 543:

APPENDIX F 12. EMERGENCY RESPONSE P

- Page 544 and 545:

APPENDIX F 12.5.3 Medical Emergency

- Page 546 and 547:

APPENDIX F safe environment. In the

- Page 548 and 549:

APPENDIX F Each SHSP may specify ad

- Page 550 and 551:

APPENDIX F 13. TRAINING In accordan

- Page 552 and 553:

APPENDIX F 14. LOGS, REPORTS, AND R

- Page 554 and 555:

APPENDIX F 15. FIELD PERSONNEL REVI

- Page 556 and 557:

APPENDIX F 16. REFERENCES Occupatio

- Page 558 and 559:

APPENDIX G APPENDIX G Construction

- Page 560 and 561:

APPENDIX G CONTENTS Section Page 1.

- Page 562 and 563:

APPENDIX G 1. INTRODUCTION TO CONST

- Page 564 and 565:

APPENDIX H APPENDIX H Permitting Pl

- Page 566 and 567:

APPENDIX H CONTENTS Section Page 1.

- Page 568 and 569:

APPENDIX H 1. PERMIT CONSIDERATIONS

- Page 570 and 571:

APPENDIX H Permit Type Agency Conta

- Page 572 and 573:

APPENDIX H Permit Type Agency Conta

- Page 574 and 575:

APPENDIX I APPENDIX I Community Rel

- Page 576 and 577:

APPENDIX J APPENDIX J Land Use Plan

- Page 578 and 579:

APPENDIX J APPENDIX K Document Cont