ONE ROOF

ONE ROOF

ONE ROOF

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

meters of concrete and 142,000 square meters of<br />

glass, among other materials.<br />

Further advancement of virtual construction<br />

Our company HOCHTIEF ViCon was formed in 2007<br />

out of a former focus of our R&D activities, virtual construction.<br />

The company is successfully concentrating<br />

on the growth market for virtual design and construction<br />

(ViCon)*, also known as Building Information Modeling<br />

(BIM). HOCHTIEF’s divisions are now using this<br />

state-of-the-art design process in numerous projects.<br />

In total, our US subsidiary Turner** has constructed<br />

more than 180 buildings using BIM. For instance, this<br />

process is enabling Turner to complete the Middle Tennessee<br />

Medical Center project in Murfreesboro approximately<br />

three months ahead of schedule. For the first<br />

time, HOCHTIEF ViCon is applying this method to one<br />

of its infrastructure projects, the Lusail City urban development<br />

project in Qatar. The 3D planning method is<br />

being used in designing and constructing the primary<br />

infrastructure, including roads, railway lines, and pipes<br />

for gas and drinking water. With the help of 3D collision<br />

tests conducted while designing the building’s technical<br />

systems, we succeeded in identifying and eliminating<br />

a number of problems in advance.<br />

John James Audubon Bridge<br />

The HOCHTIEF subsidiary Flatiron is building the longest<br />

cable-stayed bridge in the United States, crossing<br />

the Mississippi River, north of New Orleans. Completion<br />

is scheduled for 2011. Our company faces a particular<br />

challenge: Construction needs to be done during<br />

the constant changing stages of the river and its<br />

strong currents. For the construction of the footings for<br />

the main towers, which are supported on large diameter<br />

drilled shafts, Flatiron elected to use a prefabricated<br />

cofferdam system***, weighing 2,300 metric tons,<br />

❘ Information for our Shareholders ❘ ❘ Management Report ❘ ❘ Financial Statements and Notes ❘<br />

which could be erected independent of the unpredictable<br />

river elevations. Once erected, it was lowered,<br />

supported off the temporary extended drilled shafts,<br />

into the river.<br />

Historical structure’s features reconstructed<br />

Having already restored the neo-baroque Charlottenburg<br />

gate in Berlin, HOCHTIEF has now recreated two candelabra<br />

in front of the monument which had been destroyed.<br />

The ornamentation on the two approximately 22-meter<br />

candelabra was originally made of tuff, which does not<br />

weather well. It was reconstructed by HOCHTIEF using<br />

imitation tuff made from specially developed concrete.<br />

Every project powered by R&D<br />

The projects described here are perfect examples of<br />

how multi-faceted our Group’s research and development<br />

activities are. Technological or process innovations<br />

feature in every HOCHTIEF project. A major role is<br />

played in many innovations by HOCHTIEF Consult, an<br />

ideas factory that ranks among Germany’s largest engineering<br />

consultants.<br />

Close cooperation with scientists<br />

HOCHTIEF also gains R&D benefits from partnerships<br />

with universities, scientists and industry associations.<br />

In addition, HOCHTIEF‘s doctoral program allows selected<br />

employees to obtain a doctorate. The doctoral<br />

students represent an interface between the Group<br />

and the university concerned, further deepening our<br />

already close cooperation with institutes of higher edu-<br />

cation. Through our active membership of the Euro-<br />

pean Construction Technology Platform, we help to<br />

maintain excellence in the European construction industry.<br />

HOCHTIEF is also a member of ENCORD, the<br />

European Network of Construction Companies for<br />

Research and Development.<br />

History brought back to life: We<br />

reconstructed the two candelabra<br />

at the Charlottenburg gate<br />

using a newly developed type<br />

of concrete. Antique postcards<br />

guided the construction process<br />

(photo at left).<br />

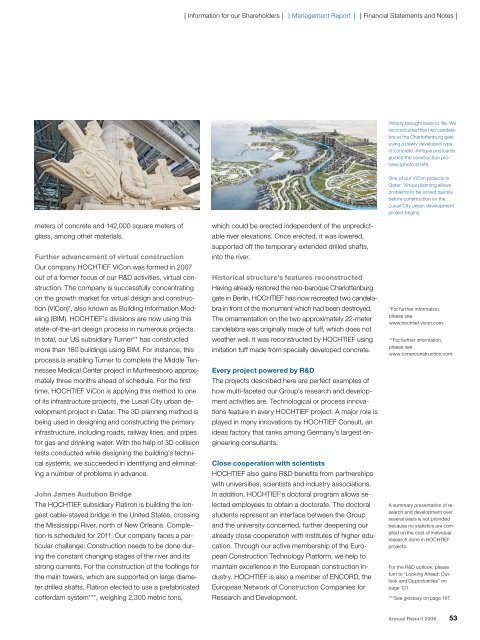

One of our ViCon projects in<br />

Qatar: Virtual planning allows<br />

problems to be solved quickly<br />

before construction on the<br />

Lusail City urban development<br />

project begins.<br />

*For further information,<br />

please see<br />

www.hochtief-vicon.com.<br />

**For further information,<br />

please see<br />

www.turnerconstruction.com.<br />

A summary presentation of research<br />

and development over<br />

several years is not provided<br />

because no statistics are compiled<br />

on the cost of individual<br />

research done in HOCHTIEF<br />

projects.<br />

For the R&D outlook, please<br />

turn to “Looking Ahead: Outlook<br />

and Opportunities” on<br />

page 121.<br />

***See glossary on page 197.<br />

Annual Report 2009 53