- Page 1:

Technical Manual:Conduits throughEm

- Page 5 and 6:

PrefaceTens of thousands of conduit

- Page 7 and 8:

Prefacecondition. The hazard classi

- Page 9:

PrefaceLakeLine MagazineMaryland Da

- Page 16:

Conduits through Embankment Dams11.

- Page 19 and 20:

Contents23 Precast concrete pipe be

- Page 21 and 22:

Contents81 On first filling, a high

- Page 23 and 24:

Contents117 This conduit was severe

- Page 25 and 26:

Contents158 An example of a histori

- Page 27 and 28:

ContentsFigures in the AppendicesNo

- Page 29 and 30:

ContentsB-33 Aerial view of Como Da

- Page 31 and 32:

ContentsB-81 Cross section of Wiste

- Page 33 and 34:

ContentsMASW, multichannel analysis

- Page 35 and 36:

Symbolsc, cohesionE', modulus of so

- Page 37 and 38:

ContentsD 3350D 4221D 4253D 4254D 4

- Page 39 and 40:

IntroductionConduits convey water f

- Page 41 and 42:

IntroductionFigure 3.—A 15-inch d

- Page 43 and 44:

Introductionunstable. When seepage

- Page 45 and 46:

IntroductionAn embankment dam with

- Page 47 and 48:

A vortex may form at the location w

- Page 49 and 50:

IntroductionWater from the reservoi

- Page 51 and 52:

IntroductionFlowing water from the

- Page 53 and 54:

IntroductionThe process of dislodgi

- Page 55 and 56:

Introductionbe observable at the su

- Page 57 and 58:

IntroductionFigure 11.—Example of

- Page 59 and 60:

Introductionwhere conduits were ass

- Page 61 and 62:

Introduction• Conduits within lev

- Page 63 and 64:

IntroductionFigure 12.—An example

- Page 65 and 66:

Introductionmore recent practiced h

- Page 67 and 68:

IntroductionThe “best practices

- Page 69 and 70:

Chapter 1GeneralConduits have been

- Page 71 and 72:

Chapter 1—GeneralFigure 14.—Ant

- Page 73 and 74:

Chapter 1—GeneralFigure 17.—Fai

- Page 75 and 76:

Chapter 1—Generalmeans the condui

- Page 77 and 78:

Chapter 1—Generalfacilitate futur

- Page 79 and 80:

Chapter 2Conduit MaterialsVarious m

- Page 81 and 82:

Chapter 2—Conduit MaterialsFigure

- Page 83 and 84:

Chapter 2—Conduit MaterialsFigure

- Page 85 and 86:

Chapter 2—Conduit Materials• Co

- Page 87 and 88:

Chapter 2—Conduit MaterialsFigure

- Page 89 and 90:

Chapter 2—Conduit MaterialsSteel

- Page 91 and 92:

Chapter 2—Conduit Materials2.3.2

- Page 93 and 94:

Chapter 2—Conduit MaterialsFigure

- Page 95 and 96:

Chapter 3Hydraulic Design of Condui

- Page 97 and 98:

Chapter 3—Hydraulic Design of Con

- Page 99 and 100:

Chapter 3—Hydraulic Design of Con

- Page 101 and 102:

Chapter 3—Hydraulic Design of Con

- Page 103 and 104:

Chapter 3—Hydraulic Design of Con

- Page 105 and 106:

Chapter 3—Hydraulic Design of Con

- Page 107 and 108:

Chapter 3—Hydraulic Design of Con

- Page 109 and 110:

Chapter 3—Hydraulic Design of Con

- Page 111 and 112:

Chapter 3—Hydraulic Design of Con

- Page 113 and 114:

Chapter 4Structural Design of Condu

- Page 115 and 116:

Chapter 4—Structural Design of Co

- Page 117 and 118:

Chapter 4—Structural Design of Co

- Page 119 and 120:

Chapter 4—Structural Design of Co

- Page 121 and 122:

Chapter 4—Structural Design of Co

- Page 123 and 124:

Chapter 4—Structural Design of Co

- Page 125 and 126:

Chapter 4—Structural Design of Co

- Page 127 and 128:

Chapter 4—Structural Design of Co

- Page 129 and 130:

Chapter 4—Structural Design of Co

- Page 131 and 132:

Chapter 4—Structural Design of Co

- Page 133 and 134:

Chapter 4—Structural Design of Co

- Page 135 and 136:

Chapter 4—Structural Design of Co

- Page 137 and 138:

Chapter 4—Structural Design of Co

- Page 139 and 140:

Chapter 4—Structural Design of Co

- Page 141 and 142:

Chapter 4—Structural Design of Co

- Page 143 and 144:

Chapter 4—Structural Design of Co

- Page 145 and 146:

Chapter 4—Structural Design of Co

- Page 147 and 148:

Chapter 4—Structural Design of Co

- Page 149 and 150:

Chapter 4—Structural Design of Co

- Page 151 and 152:

Chapter 5Foundation and Embankment

- Page 153 and 154:

Chapter 5—Foundation and Embankme

- Page 155 and 156:

Chapter 5—Foundation and Embankme

- Page 157 and 158:

Chapter 5—Foundation and Embankme

- Page 159 and 160:

Chapter 5—Foundation and Embankme

- Page 161 and 162:

Chapter 5—Foundation and Embankme

- Page 163 and 164:

Chapter 5—Foundation and Embankme

- Page 165 and 166:

Chapter 5—Foundation and Embankme

- Page 167 and 168:

Chapter 5—Foundation and Embankme

- Page 169 and 170:

Chapter 6Filter ZonesZones of desig

- Page 171 and 172:

Chapter 6—Filter Zonesseepage or

- Page 173 and 174:

Chapter 6—Filter ZonesFigure 87.

- Page 175 and 176:

Chapter 6—Filter ZonesFigure 89.

- Page 177 and 178:

Chapter 6—Filter ZonesFigure 90.

- Page 179 and 180:

Chapter 6—Filter Zones3. Upstream

- Page 181 and 182:

Chapter 6—Filter Zonesbedrock sur

- Page 183 and 184:

Chapter 6—Filter Zoneszones, and

- Page 185 and 186:

Chapter 6—Filter Zonesfiltering t

- Page 187 and 188:

Chapter 6—Filter Zonessoil. This

- Page 189 and 190:

Chapter 6—Filter Zones6.8 Specifi

- Page 191 and 192:

Chapter 6—Filter ZonesVarious deg

- Page 193 and 194:

Chapter 6—Filter Zones• For pre

- Page 195 and 196:

Chapter 7Potential Failure Modes As

- Page 197 and 198:

Chapter 7—Potential Failure Modes

- Page 199 and 200:

Chapter 7—Potential Failure Modes

- Page 201 and 202:

Chapter 7—Potential Failure Modes

- Page 203 and 204:

Chapter 7—Potential Failure Modes

- Page 205 and 206:

Chapter 7—Potential Failure Modes

- Page 207 and 208:

Chapter 7—Potential Failure Modes

- Page 209 and 210:

Chapter 7—Potential Failure Modes

- Page 211 and 212:

Chapter 7—Potential Failure Modes

- Page 213 and 214:

Chapter 7—Potential Failure Modes

- Page 215 and 216:

Chapter 8Potential Defects Associat

- Page 217 and 218:

Chapter 8—Potential Defects Assoc

- Page 219 and 220:

Chapter 8—Potential Defects Assoc

- Page 221 and 222:

Chapter 8—Potential Defects Assoc

- Page 223 and 224:

Chapter 8—Potential Defects Assoc

- Page 225 and 226:

Chapter 8—Potential Defects Assoc

- Page 227 and 228:

Chapter 8—Potential Defects Assoc

- Page 229 and 230:

Chapter 8—Potential Defects Assoc

- Page 231 and 232:

Chapter 9Inspection and Assessment

- Page 233 and 234:

Chapter 9—Inspection and Assessme

- Page 235 and 236:

Chapter 9—Inspection and Assessme

- Page 237 and 238:

Chapter 9—Inspection and Assessme

- Page 239 and 240:

Chapter 9—Inspection and Assessme

- Page 241 and 242:

Chapter 9—Inspection and Assessme

- Page 243 and 244:

Chapter 9—Inspection and Assessme

- Page 245 and 246:

Chapter 9—Inspection and Assessme

- Page 247 and 248:

Chapter 9—Inspection and Assessme

- Page 249 and 250:

Chapter 9—Inspection and Assessme

- Page 251 and 252:

Chapter 9—Inspection and Assessme

- Page 253 and 254:

Chapter 9—Inspection and Assessme

- Page 255 and 256:

Chapter 9—Inspection and Assessme

- Page 257 and 258:

Chapter 9—Inspection and Assessme

- Page 259 and 260:

Chapter 9—Inspection and Assessme

- Page 261 and 262:

Chapter 9—Inspection and Assessme

- Page 263 and 264:

Chapter 9—Inspection and Assessme

- Page 265 and 266:

Chapter 9—Inspection and Assessme

- Page 267 and 268:

Chapter 9—Inspection and Assessme

- Page 269 and 270:

Chapter 9—Inspection and Assessme

- Page 271 and 272:

Chapter 9—Inspection and Assessme

- Page 273 and 274:

Chapter 9—Inspection and Assessme

- Page 275 and 276:

Chapter 9—Inspection and Assessme

- Page 277 and 278:

Chapter 9—Inspection and Assessme

- Page 279 and 280:

Chapter 9—Inspection and Assessme

- Page 281 and 282:

Chapter 9—Inspection and Assessme

- Page 283 and 284:

Chapter 10Evaluation by Geophysical

- Page 285 and 286:

Chapter 10—Evaluation by Geophysi

- Page 287 and 288:

Chapter 10—Evaluation by Geophysi

- Page 289 and 290:

Chapter 10—Evaluation by Geophysi

- Page 291 and 292:

Chapter 10—Evaluation by Geophysi

- Page 293 and 294:

Chapter 10—Evaluation by Geophysi

- Page 295 and 296:

Chapter 10—Evaluation by Geophysi

- Page 297 and 298:

Chapter 10—Evaluation by Geophysi

- Page 299 and 300:

Chapter 11Appropriate Emergency Act

- Page 301 and 302:

Chapter 11—Appropriate Emergency

- Page 303 and 304:

Chapter 11—Appropriate Emergency

- Page 305 and 306:

Chapter 11—Appropriate Emergency

- Page 307 and 308:

Table 11.2.—Potential problems an

- Page 309 and 310:

Chapter 11—Appropriate Emergency

- Page 311 and 312:

Chapter 11—Appropriate Emergency

- Page 313 and 314:

Chapter 11—Appropriate Emergency

- Page 315 and 316:

Chapter 11—Appropriate Emergency

- Page 317 and 318:

Chapter 11—Appropriate Emergency

- Page 319 and 320:

Chapter 11—Appropriate Emergency

- Page 321 and 322:

Chapter 11—Appropriate Emergency

- Page 323 and 324:

Chapter 11—Appropriate Emergency

- Page 325 and 326:

Chapter 11—Appropriate Emergency

- Page 327 and 328:

Chapter 12Renovation of ConduitsThe

- Page 329 and 330:

Chapter 12—Renovation of Conduits

- Page 331 and 332:

Chapter 12—Renovation of Conduits

- Page 333 and 334:

Chapter 12—Renovation of Conduits

- Page 335 and 336:

Chapter 12—Renovation of Conduits

- Page 337 and 338:

Chapter 12—Renovation of Conduits

- Page 339 and 340:

Chapter 12—Renovation of Conduits

- Page 341 and 342:

Chapter 12—Renovation of Conduits

- Page 343 and 344:

Chapter 12—Renovation of Conduits

- Page 345 and 346:

Chapter 12—Renovation of Conduits

- Page 347 and 348:

Chapter 12—Renovation of Conduits

- Page 349 and 350:

Chapter 12—Renovation of Conduits

- Page 351 and 352:

Chapter 12—Renovation of Conduits

- Page 353 and 354:

Chapter 12—Renovation of Conduits

- Page 355 and 356:

Chapter 12—Renovation of Conduits

- Page 357 and 358:

Chapter 12—Renovation of Conduits

- Page 359 and 360:

Chapter 12—Renovation of Conduits

- Page 361 and 362:

Chapter 12—Renovation of Conduits

- Page 363 and 364:

Chapter 12—Renovation of Conduits

- Page 365 and 366:

Chapter 12—Renovation of Conduits

- Page 367 and 368:

Chapter 12—Renovation of Conduits

- Page 369 and 370:

Chapter 13Replacement of ConduitsGe

- Page 371 and 372:

Chapter 13—Replacement of Conduit

- Page 373 and 374:

Chapter 13—Replacement of Conduit

- Page 375 and 376:

Chapter 13—Replacement of Conduit

- Page 377 and 378:

Chapter 13—Replacement of Conduit

- Page 379 and 380:

Chapter 13—Replacement of Conduit

- Page 381 and 382:

Chapter 13—Replacement of Conduit

- Page 383 and 384:

Chapter 14Repair and Abandonment of

- Page 385 and 386:

Chapter 14—Repair and Abandonment

- Page 387 and 388:

Chapter 14—Repair and Abandonment

- Page 389 and 390:

Chapter 14—Repair and Abandonment

- Page 391 and 392:

Chapter 14—Repair and Abandonment

- Page 393 and 394:

Chapter 14—Repair and Abandonment

- Page 395 and 396:

Chapter 14—Repair and Abandonment

- Page 397 and 398:

Chapter 14—Repair and Abandonment

- Page 399 and 400:

Chapter 14—Repair and Abandonment

- Page 401 and 402:

ReferencesThe following references

- Page 403 and 404:

ReferencesBureau of Reclamation, De

- Page 405 and 406:

ReferencesCooper, Chuck, E. Wesley

- Page 407 and 408:

ReferencesJacobsen, S., “Buckling

- Page 409 and 410:

ReferencesNatural Resources Conserv

- Page 411 and 412:

ReferencesU.S. Army Corps of Engine

- Page 413 and 414:

ReferencesWooten, R. Lee, Peter S.

- Page 415 and 416:

Additional ReadingThe following ref

- Page 417 and 418:

Additional ReadingCarter, Brent H.,

- Page 419 and 420:

Additional ReadingJohnson, Brian, J

- Page 421 and 422:

Additional ReadingNatural Resources

- Page 423 and 424:

Additional ReadingU.S. Army Corps o

- Page 425 and 426:

Additional ReadingVan Aller, Hal, R

- Page 427 and 428:

GlossaryThe terms defined in this g

- Page 429 and 430:

Glossary• Backward erosion piping

- Page 431 and 432:

GlossaryCathodic protection system

- Page 433 and 434:

GlossaryConsequences (FEMA, 2004):

- Page 435 and 436:

Glossarymalfunction or abnormality

- Page 437 and 438:

GlossaryDrawdown (FEMA, 2004): The

- Page 439 and 440:

GlossaryFailure mode (FEMA, 2004):

- Page 441 and 442:

GlossaryGate chamber: An outlet wor

- Page 443 and 444:

GlossaryImpervious: Not permeable;

- Page 445 and 446:

GlossaryLeakage (FEMA, 2004): Uncon

- Page 447 and 448:

GlossaryOpen cut: An excavation thr

- Page 449 and 450:

GlossaryPolyvinyl chloride (PVC): A

- Page 451 and 452:

GlossaryResistivity: A measure of t

- Page 453 and 454:

GlossarySettlement (FEMA, 2004): Th

- Page 455 and 456:

GlossaryStandard Proctor compaction

- Page 457 and 458:

GlossaryThermoset (ASTM F 412, 2001

- Page 459 and 460:

GlossaryReferencesAmerican Concrete

- Page 461 and 462:

IndexAAbandonment of conduits, 225,

- Page 463 and 464:

IndexCompaction of backfill, 6, 10,

- Page 465 and 466:

IndexDDamembankment, 113-130, 333-3

- Page 467 and 468:

IndexExisting conduit, 23, 31, 45-5

- Page 469 and 470:

IndexHydraulic fracture, 4-11, 17,

- Page 471 and 472:

IndexMechanical caliper, 246Metal c

- Page 473 and 474:

IndexPressure flow, see Conduit, pr

- Page 475 and 476:

IndexSliplining, 39, 45-47, 51, 164

- Page 477 and 478:

IndexUUltrasonic pulse-echo, 245, 2

- Page 479 and 480:

Appendix AHistory of Antiseep Colla

- Page 481 and 482:

Appendix A—History of Antiseep Co

- Page 483 and 484:

Appendix A—History of Antiseep Co

- Page 485 and 486:

Appendix A—History of Antiseep Co

- Page 487 and 488:

Appendix BCase HistoriesIndexDam Lo

- Page 489 and 490:

Appendix B—Case HistoriesDam Loca

- Page 491 and 492:

Appendix B—Case HistoriesDam Loca

- Page 493 and 494:

Appendix B—Case HistoriesDam Loca

- Page 495 and 496:

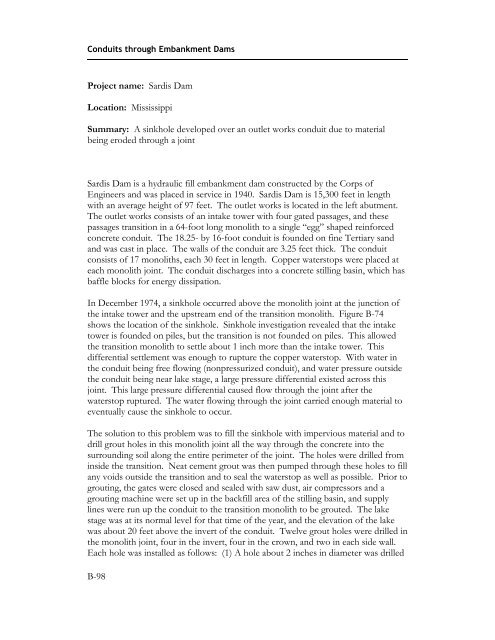

Appendix B—Case HistoriesProject

- Page 497 and 498:

Appendix B—Case HistoriesFigure B

- Page 499 and 500:

Appendix B—Case HistoriesProject

- Page 501 and 502:

Appendix B—Case HistoriesFigure B

- Page 503 and 504:

Appendix B—Case HistoriesFigure B

- Page 505 and 506:

Appendix B—Case Historiesproject,

- Page 507 and 508:

Appendix B—Case Historieswatersto

- Page 509 and 510:

Appendix B—Case HistoriesFigure B

- Page 511 and 512:

Appendix B—Case HistoriesLessons

- Page 513 and 514:

Appendix B—Case HistoriesFigure B

- Page 515 and 516:

Appendix B—Case HistoriesFigure B

- Page 517 and 518:

Appendix B—Case HistoriesFigure B

- Page 519 and 520:

Appendix B—Case HistoriesThe cond

- Page 521 and 522:

Appendix B—Case HistoriesFigure B

- Page 523 and 524:

Appendix B—Case HistoriesFigure B

- Page 525 and 526:

Appendix B—Case Historiesroadway.

- Page 527 and 528:

Appendix B—Case HistoriesFigure B

- Page 529 and 530:

Appendix B—Case Historiesentire c

- Page 531 and 532:

Appendix B—Case HistoriesProject

- Page 533 and 534:

Appendix B—Case HistoriesProject

- Page 535 and 536:

Appendix B—Case HistoriesProject

- Page 537 and 538:

Appendix B—Case Historieshauled i

- Page 539 and 540:

Appendix B—Case HistoriesProject

- Page 541 and 542: Appendix B—Case Historiescoal tar

- Page 543 and 544: Appendix B—Case Historieshistory

- Page 545 and 546: Appendix B—Case HistoriesFigure B

- Page 547 and 548: Appendix B—Case Historiesarea, a

- Page 549 and 550: Appendix B—Case HistoriesFigure B

- Page 551 and 552: Appendix B—Case HistoriesProject

- Page 553 and 554: Appendix B—Case HistoriesLessons

- Page 555 and 556: Appendix B—Case HistoriesFigure B

- Page 557 and 558: Appendix B—Case Historiespipe. Du

- Page 559 and 560: Appendix B—Case Historiesinvert o

- Page 561 and 562: Appendix B—Case HistoriesProject

- Page 563 and 564: Appendix B—Case HistoriesProject

- Page 565 and 566: Appendix B—Case HistoriesFigure B

- Page 567 and 568: Appendix B—Case Historiesdownstre

- Page 569 and 570: Appendix B—Case HistoriesFigure B

- Page 571 and 572: Appendix B—Case HistoriesProject

- Page 573 and 574: Appendix B—Case HistoriesFigure B

- Page 575 and 576: Appendix B—Case HistoriesProject

- Page 577 and 578: Appendix B—Case HistoriesLessons

- Page 579 and 580: Appendix B—Case HistoriesFigure B

- Page 581 and 582: Appendix B—Case HistoriesProject

- Page 583 and 584: Appendix B—Case HistoriesProject

- Page 585 and 586: Appendix B—Case HistoriesProject

- Page 587 and 588: Appendix B—Case HistoriesThe caus

- Page 589 and 590: Appendix B—Case HistoriesFigure B

- Page 591: Appendix B—Case HistoriesFigure B

- Page 595 and 596: Appendix B—Case HistoriesProject

- Page 597 and 598: Appendix B—Case HistoriesProject

- Page 599 and 600: Appendix B—Case HistoriesProject

- Page 601 and 602: Appendix B—Case HistoriesLessons

- Page 603 and 604: Appendix B—Case Historiesof sever

- Page 605 and 606: Appendix B—Case HistoriesLessons

- Page 607 and 608: Appendix B—Case HistoriesThe down

- Page 609 and 610: Appendix B—Case Historieshose and

- Page 611 and 612: Appendix B—Case HistoriesProject

- Page 613 and 614: Appendix B—Case HistoriesADownstr