Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4. Installation<br />

The delivered shipment should include the following (see<br />

section 2.2):<br />

- KESSEL Inspection Chamber delivered in sections<br />

(for assembly on-site)<br />

- Sewage pump(s)<br />

- Electrical Control Unit<br />

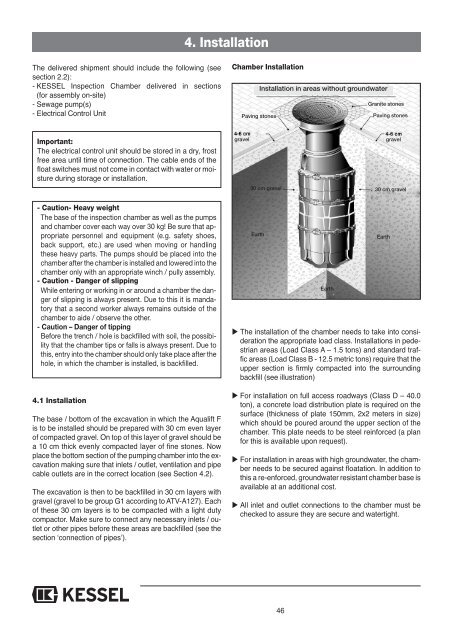

Chamber Installation<br />

Installation in areas without groundwater<br />

Granite stones<br />

Paving stones<br />

Paving stones<br />

Important:<br />

The electrical control unit should be stored in a dry, frost<br />

free area until time of connection. The cable ends of the<br />

float switches must not come in contact with water or moisture<br />

during storage or installation.<br />

gravel<br />

30 cm gravel<br />

gravel<br />

30 cm gravel<br />

- Caution- Heavy weight<br />

The base of the inspection chamber as well as the pumps<br />

and chamber cover each way over 30 kg! Be sure that appropriate<br />

personnel and equipment (e.g. safety shoes,<br />

back support, etc.) are used when moving or handling<br />

these heavy parts. The pumps should be placed into the<br />

chamber after the chamber is installed and lowered into the<br />

chamber only with an appropriate winch / pully assembly.<br />

- Caution - Danger of slipping<br />

While entering or working in or around a chamber the danger<br />

of slipping is always present. Due to this it is mandatory<br />

that a second worker always remains outside of the<br />

chamber to aide / observe the other.<br />

- Caution – Danger of tipping<br />

Before the trench / hole is backfilled with soil, the possibility<br />

that the chamber tips or falls is always present. Due to<br />

this, entry into the chamber should only take place after the<br />

hole, in which the chamber is installed, is backfilled.<br />

4.1 Installation<br />

The base / bottom of the excavation in which the Aqualift F<br />

is to be installed should be prepared with 30 cm even layer<br />

of compacted gravel. On top of this layer of gravel should be<br />

a 10 cm thick evenly compacted layer of fine stones. Now<br />

place the bottom section of the pumping chamber into the excavation<br />

making sure that inlets / outlet, ventilation and pipe<br />

cable outlets are in the correct location (see Section 4.2).<br />

The excavation is then to be backfilled in 30 cm layers with<br />

gravel (gravel to be group G1 according to ATV-A127). Each<br />

of these 30 cm layers is to be compacted with a light duty<br />

compactor. Make sure to connect any necessary inlets / outlet<br />

or other pipes before these areas are backfilled (see the<br />

section ‘connection of pipes’).<br />

Earth<br />

Earth<br />

Earth<br />

The installation of the chamber needs to take into consideration<br />

the appropriate load class. Installations in pedestrian<br />

areas (Load Class A – 1.5 tons) and standard traffic<br />

areas (Load Class B - 12.5 metric tons) require that the<br />

upper section is firmly compacted into the surrounding<br />

backfill (see illustration)<br />

For installation on full access roadways (Class D – 40.0<br />

ton), a concrete load distribution plate is required on the<br />

surface (thickness of plate 150mm, 2x2 meters in size)<br />

which should be poured around the upper section of the<br />

chamber. This plate needs to be steel reinforced (a plan<br />

for this is available upon request).<br />

For installation in areas with high groundwater, the chamber<br />

needs to be secured against floatation. In addition to<br />

this a re-enforced, groundwater resistant chamber base is<br />

available at an additional cost.<br />

All inlet and outlet connections to the chamber must be<br />

checked to assure they are secure and watertight.<br />

46