You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4. Installation<br />

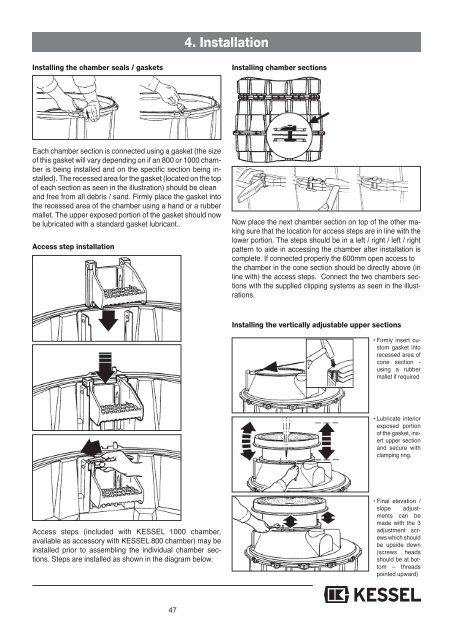

Installing the chamber seals / gaskets<br />

Installing chamber sections<br />

Each chamber section is connected using a gasket (the size<br />

of this gasket will vary depending on if an 800 or 1000 chamber<br />

is being installed and on the specific section being installed).<br />

The recessed area for the gasket (located on the top<br />

of each section as seen in the illustration) should be clean<br />

and free from all debris / sand. Firmly place the gasket into<br />

the recessed area of the chamber using a hand or a rubber<br />

mallet. The upper exposed portion of the gasket should now<br />

be lubricated with a standard gasket lubricant..<br />

Access step installation<br />

Now place the next chamber section on top of the other making<br />

sure that the location for access steps are in line with the<br />

lower portion. The steps should be in a left / right / left / right<br />

pattern to aide in accessing the chamber after installation is<br />

complete. If connected properly the 600mm open access to<br />

the chamber in the cone section should be directly above (in<br />

line with) the access steps. Connect the two chambers sections<br />

with the supplied clipping systems as seen in the illustrations.<br />

Installing the vertically adjustable upper sections<br />

• Firmly insert custom<br />

gasket into<br />

recessed area of<br />

cone section -<br />

using a rubber<br />

mallet if required<br />

• Lubricate interior<br />

exposed portion<br />

of the gasket, insert<br />

upper section<br />

and secure with<br />

clamping ring.<br />

Access steps (included with KESSEL 1000 chamber,<br />

available as accessory with KESSEL 800 chamber) may be<br />

installed prior to assembling the individual chamber sections.<br />

Steps are installed as shown in the diagram below.<br />

• Final elevation /<br />

slope adjustments<br />

can be<br />

made with the 3<br />

adjustment screws<br />

which should<br />

be upside down<br />

(screws heads<br />

should be at bottom<br />

– threads<br />

pointed upward)<br />

47