Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

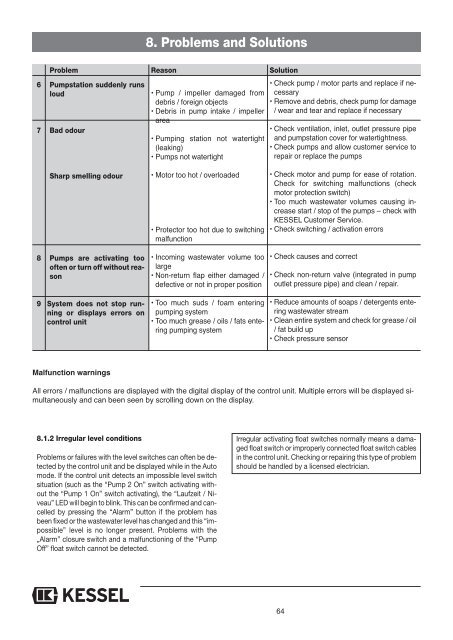

8. Problems and Solutions<br />

Problem Reason Solution<br />

6 Pumpstation suddenly runs<br />

loud<br />

7 Bad odour<br />

• Pump / impeller damaged from<br />

debris / foreign objects<br />

• Debris in pump intake / impeller<br />

area<br />

• Pumping station not watertight<br />

(leaking)<br />

• Pumps not watertight<br />

• Check pump / motor parts and replace if necessary<br />

• Remove and debris, check pump for damage<br />

/ wear and tear and replace if necessary<br />

• Check ventilation, inlet, outlet pressure pipe<br />

and pumpstation cover for watertightness.<br />

• Check pumps and allow customer service to<br />

repair or replace the pumps<br />

Sharp smelling odour<br />

8 Pumps are activating too<br />

often or turn off without reason<br />

• Motor too hot / overloaded<br />

• Protector too hot due to switching<br />

malfunction<br />

• Incoming wastewater volume too<br />

large<br />

• Non-return flap either damaged /<br />

defective or not in proper position<br />

• Check motor and pump for ease of rotation.<br />

Check for switching malfunctions (check<br />

motor protection switch)<br />

• Too much wastewater volumes causing increase<br />

start / stop of the pumps – check with<br />

KESSEL Customer Service.<br />

• Check switching / activation errors<br />

• Check causes and correct<br />

• Check non-return valve (integrated in pump<br />

outlet pressure pipe) and clean / repair.<br />

9 System does not stop running<br />

or displays errors on<br />

control unit<br />

• Too much suds / foam entering<br />

pumping system<br />

• Too much grease / oils / fats entering<br />

pumping system<br />

• Reduce amounts of soaps / detergents entering<br />

wastewater stream<br />

• Clean entire system and check for grease / oil<br />

/ fat build up<br />

• Check pressure sensor<br />

Malfunction warnings<br />

All errors / malfunctions are displayed with the digital display of the control unit. Multiple errors will be displayed simultaneously<br />

and can been seen by scrolling down on the display.<br />

8.1.2 Irregular level conditions<br />

Problems or failures with the level switches can often be detected<br />

by the control unit and be displayed while in the Auto<br />

mode. If the control unit detects an impossible level switch<br />

situation (such as the “Pump 2 On” switch activating without<br />

the “Pump 1 On” switch activating), the “Laufzeit / Niveau”<br />

LED will begin to blink. This can be confirmed and cancelled<br />

by pressing the “Alarm” button if the problem has<br />

been fixed or the wastewater level has changed and this “impossible”<br />

level is no longer present. Problems with the<br />

„Alarm” closure switch and a malfunctioning of the “Pump<br />

Off” float switch cannot be detected.<br />

Irregular activating float switches normally means a damaged<br />

float switch or improperly connected float switch cables<br />

in the control unit. Checking or repairing this type of problem<br />

should be handled by a licensed electrician.<br />

64