Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

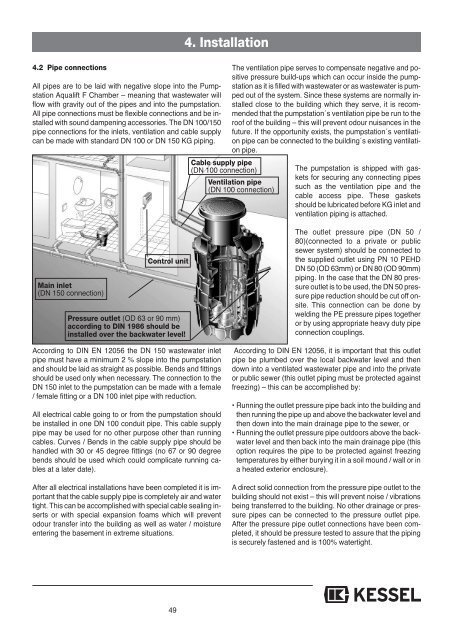

4. Installation<br />

4.2 Pipe connections<br />

All pipes are to be laid with negative slope into the Pumpstation<br />

Aqualift F Chamber – meaning that wastewater will<br />

flow with gravity out of the pipes and into the pumpstation.<br />

All pipe connections must be flexible connections and be installed<br />

with sound dampening accessories. The DN 100/150<br />

pipe connections for the inlets, ventilation and cable supply<br />

can be made with standard DN 100 or DN 150 KG piping.<br />

The ventilation pipe serves to compensate negative and positive<br />

pressure build-ups which can occur inside the pumpstation<br />

as it is filled with wastewater or as wastewater is pumped<br />

out of the system. Since these systems are normally installed<br />

close to the building which they serve, it is recommended<br />

that the pumpstation´s ventilation pipe be run to the<br />

roof of the building – this will prevent odour nuisances in the<br />

future. If the opportunity exists, the pumpstation´s ventilation<br />

pipe can be connected to the building´s existing ventilation<br />

pipe.<br />

Cable supply pipe<br />

(DN 100 connection)<br />

Ventilation pipe<br />

(DN 100 connection)<br />

The pumpstation is shipped with gaskets<br />

for securing any connecting pipes<br />

such as the ventilation pipe and the<br />

cable access pipe. These gaskets<br />

should be lubricated before KG inlet and<br />

ventilation piping is attached.<br />

Main inlet<br />

(DN 150 connection)<br />

Control unit<br />

Pressure outlet (OD 63 or 90 mm)<br />

according to DIN 1986 should be<br />

installed over the backwater level!<br />

According to DIN EN 12056 the DN 150 wastewater inlet<br />

pipe must have a minimum 2 % slope into the pumpstation<br />

and should be laid as straight as possible. Bends and fittings<br />

should be used only when necessary. The connection to the<br />

DN 150 inlet to the pumpstation can be made with a female<br />

/ female fitting or a DN 100 inlet pipe with reduction.<br />

All electrical cable going to or from the pumpstation should<br />

be installed in one DN 100 conduit pipe. This cable supply<br />

pipe may be used for no other purpose other than running<br />

cables. Curves / Bends in the cable supply pipe should be<br />

handled with 30 or 45 degree fittings (no 67 or 90 degree<br />

bends should be used which could complicate running cables<br />

at a later date).<br />

After all electrical installations have been completed it is important<br />

that the cable supply pipe is completely air and water<br />

tight. This can be accomplished with special cable sealing inserts<br />

or with special expansion foams which will prevent<br />

odour transfer into the building as well as water / moisture<br />

entering the basement in extreme situations.<br />

The outlet pressure pipe (DN 50 /<br />

80)(connected to a private or public<br />

sewer system) should be connected to<br />

the supplied outlet using PN 10 PEHD<br />

DN 50 (OD 63mm) or DN 80 (OD 90mm)<br />

piping. In the case that the DN 80 pressure<br />

outlet is to be used, the DN 50 pressure<br />

pipe reduction should be cut off onsite.<br />

This connection can be done by<br />

welding the PE pressure pipes together<br />

or by using appropriate heavy duty pipe<br />

connection couplings.<br />

According to DIN EN 12056, it is important that this outlet<br />

pipe be plumbed over the local backwater level and then<br />

down into a ventilated wastewater pipe and into the private<br />

or public sewer (this outlet piping must be protected against<br />

freezing) – this can be accomplished by:<br />

• Running the outlet pressure pipe back into the building and<br />

then running the pipe up and above the backwater level and<br />

then down into the main drainage pipe to the sewer, or<br />

• Running the outlet pressure pipe outdoors above the backwater<br />

level and then back into the main drainage pipe (this<br />

option requires the pipe to be protected against freezing<br />

temperatures by either burying it in a soil mound / wall or in<br />

a heated exterior enclosure).<br />

A direct solid connection from the pressure pipe outlet to the<br />

building should not exist – this will prevent noise / vibrations<br />

being transferred to the building. No other drainage or pressure<br />

pipes can be connected to the pressure outlet pipe.<br />

After the pressure pipe outlet connections have been completed,<br />

it should be pressure tested to assure that the piping<br />

is securely fastened and is 100% watertight.<br />

49