You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

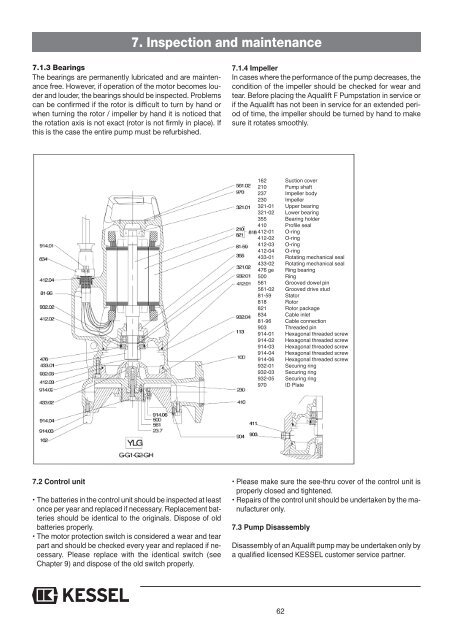

7. Inspection and maintenance<br />

7.1.3 Bearings<br />

The bearings are permanently lubricated and are maintenance<br />

free. However, if operation of the motor becomes louder<br />

and louder, the bearings should be inspected. Problems<br />

can be confirmed if the rotor is difficult to turn by hand or<br />

when turning the rotor / impeller by hand it is noticed that<br />

the rotation axis is not exact (rotor is not firmly in place). If<br />

this is the case the entire pump must be refurbished.<br />

7.1.4 Impeller<br />

In cases where the performance of the pump decreases, the<br />

condition of the impeller should be checked for wear and<br />

tear. Before placing the Aqualift F Pumpstation in service or<br />

if the Aqualift has not been in service for an extended period<br />

of time, the impeller should be turned by hand to make<br />

sure it rotates smoothly.<br />

162 Suction cover<br />

210 Pump shaft<br />

237 Impeller body<br />

230 Impeller<br />

321-01 Upper bearing<br />

321-02 Lower bearing<br />

355 Bearing holder<br />

410 Profile seal<br />

412-01 O-ring<br />

412-02 O-ring<br />

412-03 O-ring<br />

412-04 O-ring<br />

433-01 Rotating mechanical seal<br />

433-02 Rotating mechanical seal<br />

476 ge Ring bearing<br />

500 Ring<br />

561 Grooved dowel pin<br />

561-02 Grooved drive stud<br />

81-59 Stator<br />

818 Rotor<br />

821 Rotor package<br />

834 Cable inlet<br />

81-96 Cable connection<br />

903 Threaded pin<br />

914-01 Hexagonal threaded screw<br />

914-02 Hexagonal threaded screw<br />

914-03 Hexagonal threaded screw<br />

914-04 Hexagonal threaded screw<br />

914-06 Hexagonal threaded screw<br />

932-01 Securing ring<br />

932-03 Securing ring<br />

932-05 Securing ring<br />

970 ID Plate<br />

7.2 Control unit<br />

• The batteries in the control unit should be inspected at least<br />

once per year and replaced if necessary. Replacement batteries<br />

should be identical to the originals. Dispose of old<br />

batteries properly.<br />

• The motor protection switch is considered a wear and tear<br />

part and should be checked every year and replaced if necessary.<br />

Please replace with the identical switch (see<br />

Chapter 9) and dispose of the old switch properly.<br />

• Please make sure the see-thru cover of the control unit is<br />

properly closed and tightened.<br />

• Repairs of the control unit should be undertaken by the manufacturer<br />

only.<br />

7.3 Pump Disassembly<br />

Disassembly of an Aqualift pump may be undertaken only by<br />

a qualified licensed KESSEL customer service partner.<br />

62