THESE UNIQUE El Hassane Kéhien-Piho TOU - Nutridev

THESE UNIQUE El Hassane Kéhien-Piho TOU - Nutridev

THESE UNIQUE El Hassane Kéhien-Piho TOU - Nutridev

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ARTICLE IN PRESS<br />

E.H. Tou et al. / LWT 40 (2007) 1561–1569 1567<br />

for the organoleptic characteristics of the resulting<br />

MG-CMI gruel with possible enhancement of both the<br />

sweet and sour taste. The effect of these changes in<br />

organoleptic characteristics on the acceptability of the<br />

gruel will have to be assessed. As previously observed in<br />

the traditional fermentation process (Tou et al., 2006),<br />

the kinetics pattern indicates the same metabolic dominance<br />

of homofermentative LAB during the fermentation<br />

step (i.e. longer and higher production of lactic acid than of<br />

ethanol).<br />

3.2. Changes in microbial counts during the fermentation<br />

step in MG-T and MG-CMI processing methods<br />

The microbial composition (mesophilic aerobic bacteria<br />

(MAB), yeasts, LAB and (ALAB) of fermented pastes was<br />

analysed during the fermentation step (Table 2).<br />

The number of MAB and LAB increased slowly during<br />

fermentation in both processing methods, whereas yeast<br />

counts were lower and more variable with a decrease at the<br />

end of the fermentation. Similar microbiota characteristics<br />

were reported in fermented pearl millet porridge by Thaoge<br />

et al. (2003). In all processing methods, LAB were the<br />

dominant microflora and their number increased during<br />

fermentation in all samples of MG-T and MG-CMI, to<br />

reach final values of 8.83 and 8.79 log CFU/ml, respectively.<br />

Surprisingly, the lactic microflora counts were<br />

similar in both MG-T and MG-CMI pastes in the early<br />

stage of fermentation despite the fact that inoculation by<br />

backslopping was introduced in the MG-CMI processing<br />

method. This could be due to the fact that backslop<br />

inoculation enabled the microflora in MG-CMI paste to be<br />

restored to the same level as the microflora in the MG-T<br />

paste. It is interesting to note that in the MG-T processing<br />

method, the ALAB/LAB ratio decreased during fermentation,<br />

whereas in the MG-CMI processing method it<br />

remained of the same order of magnitude from the onset<br />

to the end of fermentation. One possible explanation is that<br />

in the MG-CMI process, pre-cooking before fermentation<br />

gelatinizes starch, which is a substrate for ALAB.<br />

3.3. Nutritional value of final gruels<br />

3.3.1. Proximate composition<br />

The proximate composition of MG-T and MG-CMI<br />

gruels was similar (Table 3). As expected, the incorporation<br />

of groundnuts into the pearl millet before fermentation<br />

enables a substantial increase in protein and lipid contents<br />

and DM energy value which meet recent recommendations<br />

for complementary foods (Lutter & Dewey, 2003). These<br />

results are consistent with other studies that have shown<br />

improvement of the nutritional balance of traditional<br />

fermented foods by incorporation of protein-rich materials<br />

such as grain legumes (Sanni et al., 1999; Egounlety, 2002;<br />

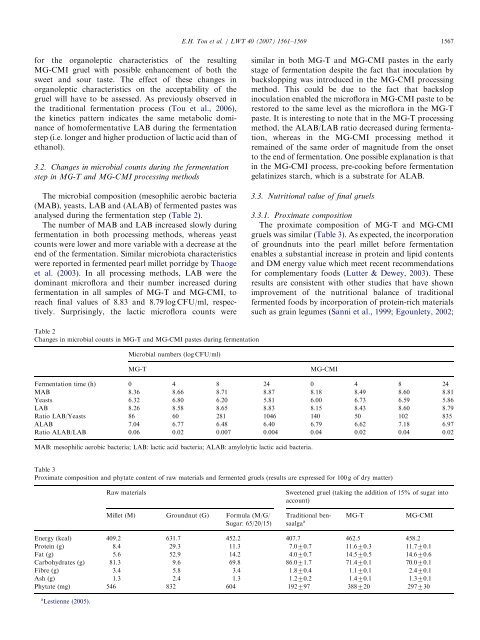

Table 2<br />

Changes in microbial counts in MG-T and MG-CMI pastes during fermentation<br />

Microbial numbers (log CFU/ml)<br />

MG-T<br />

MG-CMI<br />

Fermentation time (h) 0 4 8 24 0 4 8 24<br />

MAB 8.36 8.66 8.71 8.87 8.18 8.49 8.60 8.81<br />

Yeasts 6.32 6.80 6.20 5.81 6.00 6.73 6.59 5.86<br />

LAB 8.26 8.58 8.65 8.83 8.15 8.43 8.60 8.79<br />

Ratio LAB/Yeasts 86 60 281 1046 140 50 102 835<br />

ALAB 7.04 6.77 6.48 6.40 6.79 6.62 7.18 6.97<br />

Ratio ALAB/LAB 0.06 0.02 0.007 0.004 0.04 0.02 0.04 0.02<br />

MAB: mesophilic aerobic bacteria; LAB: lactic acid bacteria; ALAB: amylolytic lactic acid bacteria.<br />

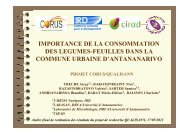

Table 3<br />

Proximate composition and phytate content of raw materials and fermented gruels (results are expressed for 100 g of dry matter)<br />

Raw materials<br />

Millet (M) Groundnut (G) Formula (M/G/<br />

Sugar: 65/20/15)<br />

Sweetened gruel (taking the addition of 15% of sugar into<br />

account)<br />

Traditional bensaalga<br />

MG-T MG-CMI<br />

a<br />

Energy (kcal) 409.2 631.7 452.2 407.7 462.5 458.2<br />

Protein (g) 8.4 29.3 11.3 7.070.7 11.670.3 11.770.1<br />

Fat (g) 5.6 52.9 14.2 4.070.7 14.570.5 14.670.6<br />

Carbohydrates (g) 81.3 9.6 69.8 86.071.7 71.470.1 70.070.1<br />

Fibre (g) 3.4 5.8 3.4 1.870.4 1.170.1 2.470.1<br />

Ash (g) 1.3 2.4 1.3 1.270.2 1.470.1 1.370.1<br />

Phytate (mg) 546 832 604 192797 388720 297730<br />

a Lestienne (2005).