THESE UNIQUE El Hassane Kéhien-Piho TOU - Nutridev

THESE UNIQUE El Hassane Kéhien-Piho TOU - Nutridev

THESE UNIQUE El Hassane Kéhien-Piho TOU - Nutridev

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

54<br />

E.H. Tou et al. / International Journal of Food Microbiology 106 (2006) 52–60<br />

Consistency of gruels was measured with a Bostwick<br />

consistometer (Bookwalter et al., 1968), at 45 -C over a period<br />

of 30 s.<br />

3. Results<br />

3.1. Description of the traditional processing of pearl millet<br />

into ben-saalga<br />

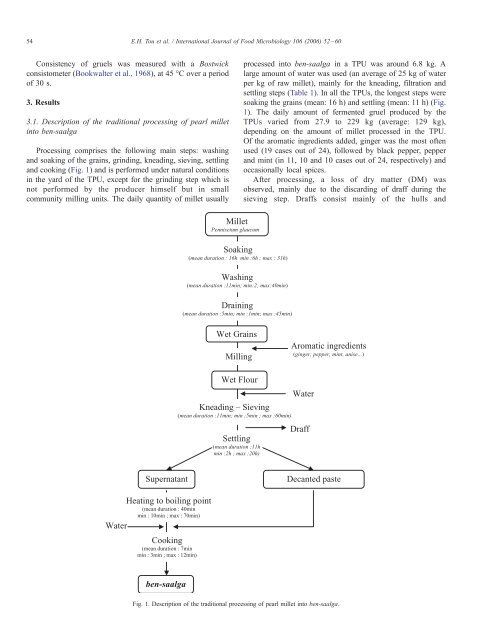

Processing comprises the following main steps: washing<br />

and soaking of the grains, grinding, kneading, sieving, settling<br />

and cooking (Fig. 1) and is performed under natural conditions<br />

in the yard of the TPU, except for the grinding step which is<br />

not performed by the producer himself but in small<br />

community milling units. The daily quantity of millet usually<br />

processed into ben-saalga in a TPU was around 6.8 kg. A<br />

large amount of water was used (an average of 25 kg of water<br />

per kg of raw millet), mainly for the kneading, filtration and<br />

settling steps (Table 1). In all the TPUs, the longest steps were<br />

soaking the grains (mean: 16 h) and settling (mean: 11 h) (Fig.<br />

1). The daily amount of fermented gruel produced by the<br />

TPUs varied from 27.9 to 229 kg (average: 129 kg),<br />

depending on the amount of millet processed in the TPU.<br />

Of the aromatic ingredients added, ginger was the most often<br />

used (19 cases out of 24), followed by black pepper, pepper<br />

and mint (in 11, 10 and 10 cases out of 24, respectively) and<br />

occasionally local spices.<br />

After processing, a loss of dry matter (DM) was<br />

observed, mainly due to the discarding of draff during the<br />

sieving step. Draffs consist mainly of the hulls and<br />

Millet<br />

Pennisetum glaucum<br />

Soaking<br />

(mean duration : 16h min :6h ; max : 31h)<br />

Washing<br />

(mean duration :11min; min:2; max:40min)<br />

Draining<br />

(mean duration :5min; min :1min; max :45min)<br />

Wet Grains<br />

Milling<br />

Aromatic ingredients<br />

(ginger, pepper, mint, anise...)<br />

Wet Flour<br />

Water<br />

Kneading – Sieving<br />

(mean duration :11min; min :5min ; max :60min)<br />

Settling<br />

(mean duration :11h<br />

min :2h ; max :20h)<br />

Draff<br />

Supernatant<br />

Decanted paste<br />

Heating to boiling point<br />

(mean duration : 40min<br />

min : 10min ; max : 70min)<br />

Water<br />

Cooking<br />

(mean duration : 7min<br />

min : 3min ; max : 12min)<br />

ben-saalga<br />

Fig. 1. Description of the traditional processing of pearl millet into ben-saalga.