- Page 2 and 3:

Springer Handbook of Acoustics

- Page 4 and 5:

Springer Handbook of Acoustics Thom

- Page 6 and 7:

Foreword The present handbook cover

- Page 8 and 9:

List of Authors Iskander Akhatov No

- Page 10 and 11:

Philippe Roux Université Joseph Fo

- Page 12 and 13:

XIV Contents 3.7 Attenuation of Sou

- Page 14 and 15:

XVI Contents 10 Concert Hall Acoust

- Page 16 and 17:

XVIII Contents 17.8 Physical Modeli

- Page 18 and 19:

XX Contents 24.5 Free-Field Microph

- Page 20 and 21:

XXII List of Abbreviations K KDP po

- Page 22 and 23:

Introduction 1. Introduction to Aco

- Page 24 and 25:

of noise have been the subject of c

- Page 26 and 27:

in order to understand how objectiv

- Page 28 and 29:

A Brief 2. A Brief History of Acous

- Page 30 and 31:

of 350 m/s for the speed of sound [

- Page 32 and 33:

number and relative strength of its

- Page 34 and 35:

To his contemporaries, Koenig was p

- Page 36 and 37:

Probably the most important use of

- Page 38 and 39:

piezoelectric ceramic compositions

- Page 40 and 41:

surveys together [2.46]. Masking of

- Page 42 and 43:

ther of computer music, since he de

- Page 44 and 45:

Basic 3. Linear Basic Linear Acoust

- Page 46 and 47:

M average molecular weight n unit v

- Page 48 and 49:

a) b) S v.n ∆t ∆S V |v| ∆t n

- Page 50 and 51:

temperature, q =−κ∇T , (3.16)

- Page 52 and 53:

The equivalent density M/V is conse

- Page 54 and 55:

Basic Linear Acoustics 3.3 Equation

- Page 56 and 57:

Because any vector field may be dec

- Page 58 and 59:

The latter and (3.84), in a manner

- Page 60 and 61:

assumed to have no ambient motion,

- Page 62 and 63:

Because the friction associated wit

- Page 64 and 65:

3.5 Waves of Constant Frequency One

- Page 66 and 67:

3.5.4 Time Averages of Products Whe

- Page 68 and 69:

as well as symmetry considerations,

- Page 70 and 71:

The auxiliary internal variables th

- Page 72 and 73:

Then the transient at a distant pos

- Page 74 and 75:

ω ′ = 0, and this is consistent

- Page 76 and 77:

1.0 10 -1 10 -2 10 -3 10 -4 10 -5 A

- Page 78 and 79:

This yields the interpretation that

- Page 80 and 81:

direction of propagation when a pla

- Page 82 and 83:

so the time-averaged incident energ

- Page 84 and 85:

Although the simple result of (3.31

- Page 86 and 87:

ut, also in keeping with the linear

- Page 88 and 89:

equation, the two differential equa

- Page 90 and 91:

Rodrigues relation, one has �1

- Page 92 and 93:

for the derivative.) In the asympto

- Page 94 and 95:

The differential scattering cross s

- Page 96 and 97:

elow) is F(t) = (2c) 1/2 �t −

- Page 98 and 99:

0.5 0 -0.5 -1.0 -1.5 0 Y0(η) (π/2

- Page 100 and 101:

is the Wronskian for the Bessel and

- Page 102 and 103:

The function qS is termed the sourc

- Page 104 and 105:

The appropriate identification for

- Page 106 and 107:

where jℓ is the spherical Bessel

- Page 108 and 109:

this subtlety taken into account, o

- Page 110 and 111:

U(x) Basic Linear Acoustics 3.15 Wa

- Page 112 and 113:

is ordinarily valid. With these ass

- Page 114 and 115:

along rays. These can be regarded a

- Page 116 and 117:

A(x0) x0 A(x) Fig. 3.53 Sketch of a

- Page 118 and 119:

possible, and one where neither the

- Page 120 and 121:

which is independent of the z-coord

- Page 122 and 123:

[3.108], and Carslaw [3.109]. In th

- Page 124 and 125:

where C(X)andS(X) are the Fresnel i

- Page 126 and 127:

Fig. 3.60 Characteristic diffractio

- Page 128 and 129:

of elastic solids, Trans. Camb. Phi

- Page 130 and 131:

3.101 J.B. Keller: Geometrical acou

- Page 132 and 133:

114 Part A Propagation of Sound Par

- Page 134 and 135:

116 Part A Propagation of Sound Par

- Page 136 and 137:

118 Part A Propagation of Sound Par

- Page 138 and 139:

120 Part A Propagation of Sound Par

- Page 140 and 141:

122 Part A Propagation of Sound Par

- Page 142 and 143:

124 Part A Propagation of Sound Par

- Page 144 and 145:

126 Part A Propagation of Sound Par

- Page 146 and 147:

128 Part A Propagation of Sound Par

- Page 148 and 149:

130 Part A Propagation of Sound Par

- Page 150 and 151:

132 Part A Propagation of Sound Par

- Page 152 and 153:

134 Part A Propagation of Sound Par

- Page 154 and 155:

136 Part A Propagation of Sound Par

- Page 156 and 157:

138 Part A Propagation of Sound Par

- Page 158 and 159:

140 Part A Propagation of Sound Par

- Page 160 and 161:

142 Part A Propagation of Sound Par

- Page 162 and 163:

144 Part A Propagation of Sound Par

- Page 164 and 165:

146 Part A Propagation of Sound Par

- Page 166 and 167:

Underwater 5. Underwater Acoustics

- Page 168 and 169:

5.1 Ocean Acoustic Environment The

- Page 170 and 171:

Long-Range Propagation Paths Figure

- Page 172 and 173:

tal direction, there is no loss ass

- Page 174 and 175:

equivalent circuit, as shown in Fig

- Page 176 and 177:

Attenuation á (dB/km) 1000 100 10

- Page 178 and 179:

5.2.5 Ambient Noise There are essen

- Page 180 and 181:

ubble natural acoustic resonance ω

- Page 182 and 183:

a bubbly medium (and for the simple

- Page 184 and 185:

As discussed, because detection inv

- Page 186 and 187:

(1/A)∇ 2 A ≪ K 2 )sothat(5.34)

- Page 188 and 189:

water, where the deep sound channel

- Page 190 and 191:

egion in the form p(r, z) = ψ(r, z

- Page 192 and 193:

5.4.6 Propagation and Transmission

- Page 194 and 195:

tegration interval. The source puls

- Page 196 and 197:

5.6 SONAR Array Processing Signal p

- Page 198 and 199:

former output is: �∞ b(θ,t) =

- Page 200 and 201:

Fig. 5.37 Angle-versus-time represe

- Page 202 and 203:

5.7 Active SONAR Processing Depth M

- Page 204 and 205:

a factor when there is a reverberan

- Page 206 and 207:

depth measurements that correspond

- Page 208 and 209:

along the cross-shelf track taken b

- Page 210 and 211:

time as a result of multiple paths,

- Page 212 and 213:

technique is very sensitive, and ex

- Page 214 and 215:

Fig. 5.57a,b Typical echogram obtai

- Page 216 and 217:

Frequency (Hz) 150 100 50 0 0 a) b)

- Page 218 and 219:

out. These data allow for study of

- Page 220 and 221:

5.59 G. Raleigh, J.M. Cioffi: Spati

- Page 222 and 223:

Physical 6. Physical Acou Acoustics

- Page 224 and 225:

where I is the intensity of the sou

- Page 226 and 227:

Wave velocity The wall exerts a dow

- Page 228 and 229:

destructively interfered with one a

- Page 230 and 231:

or: � � p2 � rms SPL = 10 log

- Page 232 and 233:

6.1.4 Wave Propagation in Solids Si

- Page 234 and 235:

where c is again the wave speed and

- Page 236 and 237:

measured. Some resonances are cause

- Page 238 and 239:

as 50 µmto5µm through one oscilla

- Page 240 and 241:

the number of false positives and m

- Page 242 and 243:

with the small mass), and frequency

- Page 244 and 245:

Laser Lens 1 Circular aperture Fig.

- Page 246 and 247:

Ground ring Insulator Sample Resist

- Page 248 and 249:

Energy ratio 1.0 0.8 0.6 0.4 Calcul

- Page 250 and 251:

terms. In this equation γ is the r

- Page 252 and 253:

directly. The nonlinearity paramete

- Page 254 and 255:

Thermoacoust 7. Thermoacoustics The

- Page 256 and 257:

Table 7.1 The acoustic-electric ana

- Page 258 and 259:

walls of the pores. (Positive G ind

- Page 260 and 261:

a) b) c) C reso d) δtherm e) p 0 U

- Page 262 and 263:

a) b) UA,l c) d) E 0 Q A Q A TA TA

- Page 264 and 265:

tor. This eliminates the need to le

- Page 266 and 267:

to this consumption of acoustic pow

- Page 268 and 269:

The traditional Stirling refrigerat

- Page 270 and 271:

Washington 1986) pp. 550-554, Softw

- Page 272 and 273:

258 Part B Physical and Nonlinear A

- Page 274 and 275:

260 Part B Physical and Nonlinear A

- Page 276 and 277:

262 Part B Physical and Nonlinear A

- Page 278 and 279:

264 Part B Physical and Nonlinear A

- Page 280 and 281:

266 Part B Physical and Nonlinear A

- Page 282 and 283:

268 Part B Physical and Nonlinear A

- Page 284 and 285:

270 Part B Physical and Nonlinear A

- Page 286 and 287:

272 Part B Physical and Nonlinear A

- Page 288 and 289:

274 Part B Physical and Nonlinear A

- Page 290 and 291:

276 Part B Physical and Nonlinear A

- Page 292 and 293:

278 Part B Physical and Nonlinear A

- Page 294 and 295:

280 Part B Physical and Nonlinear A

- Page 296 and 297:

282 Part B Physical and Nonlinear A

- Page 298 and 299:

284 Part B Physical and Nonlinear A

- Page 300 and 301:

286 Part B Physical and Nonlinear A

- Page 302 and 303:

288 Part B Physical and Nonlinear A

- Page 304 and 305:

290 Part B Physical and Nonlinear A

- Page 306 and 307:

292 Part B Physical and Nonlinear A

- Page 308 and 309:

294 Part B Physical and Nonlinear A

- Page 310 and 311:

296 Part B Physical and Nonlinear A

- Page 312 and 313:

Acoustics 9. Acoustics in Halls for

- Page 314 and 315:

parameters, so we can assist in bui

- Page 316 and 317:

weeks or even years is less reliabl

- Page 318 and 319:

9.3.1 Reverberation Time Reverberan

- Page 320 and 321:

selected). A distance different fro

- Page 322 and 323:

ing sound, as will naturally be exp

- Page 324 and 325:

of the sound fields. Consequently,

- Page 326 and 327:

e derived from interrupted noise de

- Page 328 and 329:

Acoustics in Halls for Speech and M

- Page 330 and 331:

espectively, can be calculated from

- Page 332 and 333:

ated by the architects. However, on

- Page 334 and 335:

of C and G. However, as all the ind

- Page 336 and 337:

F b d F n I S Fb Fn S d F n/F b d/d

- Page 338 and 339:

HS S èn ã d0 P0 rn Position of ey

- Page 340 and 341:

Time T (s) 2.5 2 1.5 1 5 10 15 Acou

- Page 342 and 343:

floor can be tilted to reduce volum

- Page 344 and 345:

ÄLcurv (dB) 10 8 6 4 2 0 -2 -4 -6

- Page 346 and 347:

Acoustics in Halls for Speech and M

- Page 348 and 349:

Acoustics in Halls for Speech and M

- Page 350 and 351:

Acoustics in Halls for Speech and M

- Page 352 and 353:

Seating capacity 2662 1 915 + 324 2

- Page 354 and 355:

Acoustics in Halls for Speech and M

- Page 356 and 357:

4 3 2 1 Acoustics in Halls for Spee

- Page 358 and 359:

cially in auditoria with T values l

- Page 360 and 361:

esonance (AR)andmultichannel reverb

- Page 362 and 363:

Concert 10. Concert Hall Acoustics

- Page 364 and 365:

Concert Hall Acoustics Based on Sub

- Page 366 and 367:

0 0 Concert Hall Acoustics Based on

- Page 368 and 369:

mately by Concert Hall Acoustics Ba

- Page 370 and 371:

Concert Hall Acoustics Based on Sub

- Page 372 and 373:

10.1.5 Specialization of Cerebral H

- Page 374 and 375:

The other (n − 1) bits indicated

- Page 376 and 377:

As for the conflicting requirements

- Page 378 and 379:

have mainly been concerned with tem

- Page 380 and 381:

a) c) S S -4.3 -2.8 -2.0 -3.5 -3dB

- Page 382 and 383:

Concert Hall Acoustics Based on Sub

- Page 384 and 385:

Concert Hall Acoustics Based on Sub

- Page 386 and 387:

Concert Hall Acoustics Based on Sub

- Page 388 and 389:

Concert Hall Acoustics Based on Sub

- Page 390 and 391:

Concert Hall Acoustics Based on Sub

- Page 392 and 393:

Concert Hall Acoustics Based on Sub

- Page 394 and 395:

Concert Hall Acoustics Based on Sub

- Page 396 and 397:

a model of the auditory-brain syste

- Page 398 and 399:

Building 11. Building Acou Acoustic

- Page 400 and 401:

Pressure Maximum Minimum 0 D Distan

- Page 402 and 403:

Table 11.1 Absorption coefficients

- Page 404 and 405:

Absorption coefficient α 1 0 Frequ

- Page 406 and 407:

is of key importance in rooms where

- Page 408 and 409:

Table 11.4 Transmission loss and ST

- Page 410 and 411:

TL of wall - (TL of door, window or

- Page 412 and 413:

Table 11.7 Generalized noise reduct

- Page 414 and 415:

Masking sound pressure level (dB) 5

- Page 416 and 417:

As for the room criterion (RC) meth

- Page 418 and 419:

11.5 Noise Control Methods for Buil

- Page 420 and 421:

Neoprene pads (30 durometer) with a

- Page 422 and 423:

Concrete Caulk around perimeter Vib

- Page 424 and 425:

Trim board to conceal gap (fasten o

- Page 426 and 427:

Gypsum board partition (as schedule

- Page 428 and 429:

Double-layer ribbed or waffle neopr

- Page 430 and 431:

11.6 Acoustical Privacy in Building

- Page 432 and 433:

Table 11.9 AI,SIIandPIforopenplanof

- Page 434 and 435:

Electronic sound masking in plenum

- Page 436 and 437:

E 1179 Standard Specification for S

- Page 438 and 439:

430 Part D Hearing and Signal Proce

- Page 440 and 441:

432 Part D Hearing and Signal Proce

- Page 442 and 443:

434 Part D Hearing and Signal Proce

- Page 444 and 445:

436 Part D Hearing and Signal Proce

- Page 446 and 447:

438 Part D Hearing and Signal Proce

- Page 448 and 449:

440 Part D Hearing and Signal Proce

- Page 450 and 451:

442 Part D Hearing and Signal Proce

- Page 452 and 453:

444 Part D Hearing and Signal Proce

- Page 454 and 455:

446 Part D Hearing and Signal Proce

- Page 456 and 457:

448 Part D Hearing and Signal Proce

- Page 458 and 459:

450 Part D Hearing and Signal Proce

- Page 460 and 461:

452 Part D Hearing and Signal Proce

- Page 462 and 463:

454 Part D Hearing and Signal Proce

- Page 464 and 465:

456 Part D Hearing and Signal Proce

- Page 466 and 467:

Psychoacoust 13. Psychoacoustics Ps

- Page 468 and 469:

Absolute threshold (dB SPL) 100 90

- Page 470 and 471:

the signal. By using this off-cente

- Page 472 and 473:

is as a crude indicator of the exci

- Page 474 and 475:

Relative response (dB) 100 90 80 70

- Page 476 and 477:

In a variation of this procedure, t

- Page 478 and 479:

Level of matching noise (dB) 100 90

- Page 480 and 481:

13.4 Temporal Processing in the Aud

- Page 482 and 483:

Most models include an initial stag

- Page 484 and 485:

The components were either uniforml

- Page 486 and 487:

(Frequency DL)/ERBN 0.2 0.1 0.05 0.

- Page 488 and 489:

elaborate place models have been pr

- Page 490 and 491:

13.6 Timbre Perception 13.6.1 Time-

- Page 492 and 493:

the duplex theory of sound localiza

- Page 494 and 495:

harmonic (by shifting the frequency

- Page 496 and 497:

sive. While some studies have been

- Page 498 and 499:

sentences (see Fig. 13.20). They va

- Page 500 and 501:

components is usually only perceive

- Page 502 and 503:

References 13.1 ISO 389-7: Acoustic

- Page 504 and 505:

13.74 D. Ronken: Monaural detection

- Page 506 and 507:

asymmetric function, J. Acoust. Soc

- Page 508 and 509:

13.211 J. Vliegen, A.J. Oxenham: Se

- Page 510 and 511:

504 Part D Hearing and Signal Proce

- Page 512 and 513:

506 Part D Hearing and Signal Proce

- Page 514 and 515:

508 Part D Hearing and Signal Proce

- Page 516 and 517:

510 Part D Hearing and Signal Proce

- Page 518 and 519:

512 Part D Hearing and Signal Proce

- Page 520 and 521:

514 Part D Hearing and Signal Proce

- Page 522 and 523:

516 Part D Hearing and Signal Proce

- Page 524 and 525:

518 Part D Hearing and Signal Proce

- Page 526 and 527:

520 Part D Hearing and Signal Proce

- Page 528 and 529:

522 Part D Hearing and Signal Proce

- Page 530 and 531:

524 Part D Hearing and Signal Proce

- Page 532 and 533:

526 Part D Hearing and Signal Proce

- Page 534 and 535:

528 Part D Hearing and Signal Proce

- Page 536 and 537:

530 Part D Hearing and Signal Proce

- Page 538 and 539:

534 Part E Music, Speech, Electroac

- Page 540 and 541:

536 Part E Music, Speech, Electroac

- Page 542 and 543:

538 Part E Music, Speech, Electroac

- Page 544 and 545:

540 Part E Music, Speech, Electroac

- Page 546 and 547:

542 Part E Music, Speech, Electroac

- Page 548 and 549:

544 Part E Music, Speech, Electroac

- Page 550 and 551:

546 Part E Music, Speech, Electroac

- Page 552 and 553:

548 Part E Music, Speech, Electroac

- Page 554 and 555:

550 Part E Music, Speech, Electroac

- Page 556 and 557:

552 Part E Music, Speech, Electroac

- Page 558 and 559:

554 Part E Music, Speech, Electroac

- Page 560 and 561:

556 Part E Music, Speech, Electroac

- Page 562 and 563:

558 Part E Music, Speech, Electroac

- Page 564 and 565:

560 Part E Music, Speech, Electroac

- Page 566 and 567:

562 Part E Music, Speech, Electroac

- Page 568 and 569:

564 Part E Music, Speech, Electroac

- Page 570 and 571:

566 Part E Music, Speech, Electroac

- Page 572 and 573:

568 Part E Music, Speech, Electroac

- Page 574 and 575:

570 Part E Music, Speech, Electroac

- Page 576 and 577:

572 Part E Music, Speech, Electroac

- Page 578 and 579:

574 Part E Music, Speech, Electroac

- Page 580 and 581:

576 Part E Music, Speech, Electroac

- Page 582 and 583:

578 Part E Music, Speech, Electroac

- Page 584 and 585:

580 Part E Music, Speech, Electroac

- Page 586 and 587:

582 Part E Music, Speech, Electroac

- Page 588 and 589:

584 Part E Music, Speech, Electroac

- Page 590 and 591:

586 Part E Music, Speech, Electroac

- Page 592 and 593:

588 Part E Music, Speech, Electroac

- Page 594 and 595:

590 Part E Music, Speech, Electroac

- Page 596 and 597:

592 Part E Music, Speech, Electroac

- Page 598 and 599:

594 Part E Music, Speech, Electroac

- Page 600 and 601:

596 Part E Music, Speech, Electroac

- Page 602 and 603:

598 Part E Music, Speech, Electroac

- Page 604 and 605:

600 Part E Music, Speech, Electroac

- Page 606 and 607:

602 Part E Music, Speech, Electroac

- Page 608 and 609:

604 Part E Music, Speech, Electroac

- Page 610 and 611:

606 Part E Music, Speech, Electroac

- Page 612 and 613:

608 Part E Music, Speech, Electroac

- Page 614 and 615:

610 Part E Music, Speech, Electroac

- Page 616 and 617:

612 Part E Music, Speech, Electroac

- Page 618 and 619:

614 Part E Music, Speech, Electroac

- Page 620 and 621:

616 Part E Music, Speech, Electroac

- Page 622 and 623:

618 Part E Music, Speech, Electroac

- Page 624 and 625:

620 Part E Music, Speech, Electroac

- Page 626 and 627:

622 Part E Music, Speech, Electroac

- Page 628 and 629:

624 Part E Music, Speech, Electroac

- Page 630 and 631:

626 Part E Music, Speech, Electroac

- Page 632 and 633:

628 Part E Music, Speech, Electroac

- Page 634 and 635:

630 Part E Music, Speech, Electroac

- Page 636 and 637:

632 Part E Music, Speech, Electroac

- Page 638 and 639:

634 Part E Music, Speech, Electroac

- Page 640 and 641:

636 Part E Music, Speech, Electroac

- Page 642 and 643:

638 Part E Music, Speech, Electroac

- Page 644 and 645:

640 Part E Music, Speech, Electroac

- Page 646 and 647:

642 Part E Music, Speech, Electroac

- Page 648 and 649:

644 Part E Music, Speech, Electroac

- Page 650 and 651:

646 Part E Music, Speech, Electroac

- Page 652 and 653:

648 Part E Music, Speech, Electroac

- Page 654 and 655:

650 Part E Music, Speech, Electroac

- Page 656 and 657:

652 Part E Music, Speech, Electroac

- Page 658 and 659:

654 Part E Music, Speech, Electroac

- Page 660 and 661:

656 Part E Music, Speech, Electroac

- Page 662 and 663:

658 Part E Music, Speech, Electroac

- Page 664 and 665:

660 Part E Music, Speech, Electroac

- Page 666 and 667:

662 Part E Music, Speech, Electroac

- Page 668 and 669:

664 Part E Music, Speech, Electroac

- Page 670 and 671:

666 Part E Music, Speech, Electroac

- Page 672 and 673:

The 16. The Human Human Voice in Sp

- Page 674 and 675:

uation, the effect of gravity is in

- Page 676 and 677:

piratory muscles (the internal inte

- Page 678 and 679:

Mean Ps (cm H2O) 50 40 30 20 10 0 D

- Page 680 and 681:

Glottal flow Closed Opening Open Cl

- Page 682 and 683:

Transglottal airflow (l/s) 0.4 0.2

- Page 684 and 685:

Mean spectrum level (dB) -30 -40 -5

- Page 686 and 687:

20 10 0 -10 -20 -30 -40 -50 0 i y u

- Page 688 and 689:

Mean level (dB) 0 -10 -20 -30 -40 1

- Page 690 and 691:

This topic was addressed by Ladefog

- Page 692 and 693:

Fig. 16.29 Acoustic consequences of

- Page 694 and 695:

Bass i e u Alto Tenor o ε œ æ Th

- Page 696 and 697:

100 80 60 40 20 0 -20 100 80 60 40

- Page 698 and 699:

tours for [� ]and[Ù ] sampled at

- Page 700 and 701:

Rapp [16.100] asked three native sp

- Page 702 and 703:

Utterance command T0 T3 Accent comm

- Page 704 and 705:

The # symbol indicates the possibil

- Page 706 and 707:

Second formant frequency (Hz) 2500

- Page 708 and 709:

tional rather than absolute (à la

- Page 710 and 711:

16.7 P. Ladefoged, M.H. Draper, D.

- Page 712 and 713:

esonance imaging: Vowels, J. Acoust

- Page 714 and 715:

16.139 A. Eriksson: Aspects of Swed

- Page 716 and 717:

Computer 17. Computer Mu Music This

- Page 718 and 719:

Quantum step Amplitude Quantization

- Page 720 and 721:

Some might notice that linear inter

- Page 722 and 723:

pers, textbooks, patents, etc. Furt

- Page 724 and 725:

0:00.0 0.5 0 Computer Music 17.3 Ad

- Page 726 and 727:

(0,0) (0,1) (1,1) (0,2) (1,2) (0,3)

- Page 728 and 729:

synthesizing vocoder. The main diff

- Page 730 and 731:

x(n) + z -1 z -1 Scattering junctio

- Page 732 and 733:

230 Hz FOF 1100 Hz FOF 1700 Hz FOF

- Page 734 and 735:

0 y + - Computer Music 17.8 Physica

- Page 736 and 737:

-1 (1-ß )×length Velocity + Veloc

- Page 738 and 739:

0 -30 (dB) -60 0 1.5 3 4.5 (kHz) Fi

- Page 740 and 741:

17.10 Composition The history of co

- Page 742 and 743:

and variance of the features can be

- Page 744 and 745:

17.20 J.L. Kelly Jr., C.C. Lochbaum

- Page 746 and 747:

Audio 18. Audio and Electroacoustic

- Page 748 and 749:

Alexander Graham Bell filed his pat

- Page 750 and 751:

on magnetic stripes. A common arran

- Page 752 and 753:

60 40 20 0 SPL-sound pressure level

- Page 754 and 755:

Interaural intensity difference (dB

- Page 756 and 757:

with equalization, without incurrin

- Page 758 and 759:

Fig. 18.8 Sine wave with crossover

- Page 760 and 761:

18.3.8 Dynamic Range Dynamic range

- Page 762 and 763:

Directly actuated type Diaphragm ty

- Page 764 and 765:

effective pickup pattern of the arr

- Page 766 and 767:

attempts to apply complementary com

- Page 768 and 769:

Most of the issues relating to spea

- Page 770 and 771:

nificant design considerations. At

- Page 772 and 773:

Some appreciation of the performanc

- Page 774 and 775:

pre-digital reverberators were elec

- Page 776 and 777:

and ‘s’ in English text - may b

- Page 778 and 779:

content of rest of the signal spect

- Page 780 and 781:

cross the head, in opposite directi

- Page 782 and 783:

18.2 J. Sterne: The Audible Past (D

- Page 784 and 785:

18.71 T. Sporer: Creating, assessin

- Page 786 and 787:

786 Part F Biological and Medical A

- Page 788 and 789:

788 Part F Biological and Medical A

- Page 790 and 791:

790 Part F Biological and Medical A

- Page 792 and 793:

792 Part F Biological and Medical A

- Page 794 and 795:

794 Part F Biological and Medical A

- Page 796 and 797:

796 Part F Biological and Medical A

- Page 798 and 799:

798 Part F Biological and Medical A

- Page 800 and 801:

800 Part F Biological and Medical A

- Page 802 and 803:

802 Part F Biological and Medical A

- Page 804 and 805:

804 Part F Biological and Medical A

- Page 806 and 807:

806 Part F Biological and Medical A

- Page 808 and 809:

808 Part F Biological and Medical A

- Page 810 and 811:

810 Part F Biological and Medical A

- Page 812 and 813:

812 Part F Biological and Medical A

- Page 814 and 815:

814 Part F Biological and Medical A

- Page 816 and 817:

816 Part F Biological and Medical A

- Page 818 and 819:

818 Part F Biological and Medical A

- Page 820 and 821:

820 Part F Biological and Medical A

- Page 822 and 823:

822 Part F Biological and Medical A

- Page 824 and 825:

824 Part F Biological and Medical A

- Page 826 and 827:

826 Part F Biological and Medical A

- Page 828 and 829:

828 Part F Biological and Medical A

- Page 830 and 831:

830 Part F Biological and Medical A

- Page 832 and 833:

832 Part F Biological and Medical A

- Page 834 and 835:

834 Part F Biological and Medical A

- Page 836 and 837:

836 Part F Biological and Medical A

- Page 838 and 839:

Medical 21. Medical Acous Acoustics

- Page 840 and 841:

21.1 Introduction to Medical Acoust

- Page 842 and 843:

Auscultation location Right & left

- Page 844 and 845:

portance. The Strouhal number has b

- Page 846 and 847:

Fig. 21.3 Phono-cardiograph transdu

- Page 848 and 849:

Amplitude 8 6 4 2 0 -2 -4 -6 Displa

- Page 850 and 851:

λ1 = c1 / fus θ1 λ2 = c2 / fus

- Page 852 and 853:

lood flow can be resolved if the si

- Page 854 and 855:

vided in the image thickness direct

- Page 856 and 857:

not as predicted, because the wave

- Page 858 and 859:

Fig. 21.18a,b Quadrature Doppler de

- Page 860 and 861:

a) b) c) 100 0 V mV 10 0 a = 13 a =

- Page 862 and 863:

Ultrasound contact gel Position enc

- Page 864 and 865:

a) 10 cm b) c) 10 cm Fig. 21.32a-c

- Page 866 and 867:

a) Pin B Pin A Ultrasound line b) M

- Page 868 and 869:

Organ Patient Ultrasound transducer

- Page 870 and 871:

systems cannot tell the difference

- Page 872 and 873:

40 µm can be resolved. For a 10 kH

- Page 874 and 875:

a) b) c) d) Medical Acoustics 21.4

- Page 876 and 877:

Fig. 21.54 Doppler spectral wavefor

- Page 878 and 879:

10 20 30 10 20 30 Pre-exercise B-mo

- Page 880 and 881:

Vibrations in a punctured artery De

- Page 882 and 883:

the veins and diffuse into the inte

- Page 884 and 885:

21.5.3 Agitated Saline and Patent F

- Page 886 and 887:

transported by those cells and/or r

- Page 888 and 889:

1 0.8 0.6 0.4 0.2 0 Relative power

- Page 890 and 891:

High intensity focused ultrasound h

- Page 892 and 893:

a) b) c) Fig. 21.74a-c B-mode imagi

- Page 894 and 895:

provided simple metrics for the lik

- Page 896 and 897:

thickness of the carotid arteries,

- Page 898 and 899:

Structural 22. Structural Acoustics

- Page 900 and 901:

Structural Acoustics and Vibrations

- Page 902 and 903:

Magnitude (arb. units) 1.4 1.2 1.0

- Page 904 and 905:

This does not include the case wher

- Page 906 and 907:

the mass matrix is taken to be cons

- Page 908 and 909:

Magnitude (dB) -10 -30 -50 0 1 2 3

- Page 910 and 911:

where D(ω) = ω 4 − 2iω 3�

- Page 912 and 913:

form y(x, t) = � Φn(x)qn(t) . (2

- Page 914 and 915:

first to solve the wave equation (2

- Page 916 and 917:

5 3 1 -1 -3 -5 0 1 2 3 4 5 6 7 8 9

- Page 918 and 919:

conditions at each end) are necessa

- Page 920 and 921:

from which we can derive through (2

- Page 922 and 923:

In this case, the eigenfrequencies

- Page 924 and 925:

of radiation modes and their link w

- Page 926 and 927:

Finally, the displacement is ˜ξ(x

- Page 928 and 929:

notes the value of this eigenmode a

- Page 930 and 931:

Pm = ˙Q H [Rs + Ra] ˙Q , (22.262)

- Page 932 and 933:

where and Ra = 2ζaω0 M Z(s) = zL

- Page 934 and 935:

Radiated Power. The mean acoustic p

- Page 936 and 937:

(22.318) can be written ξ(x, y, t)

- Page 938 and 939:

Denoting the eigenfrequencies and e

- Page 940 and 941:

Magnitude (arb. units) 3 2 1 0 -1 -

- Page 942 and 943:

for any real symmetric tensor Xij.

- Page 944 and 945:

F(N) 1 0.5 0 -0.5 -1 -1 -0.8 -0.6 -

- Page 946 and 947:

whose solution is θ1 = A cos ωτ.

- Page 948 and 949:

4.5 3.5 2.5 1.5 A 0.5 0 0.5 1.0 1.5

- Page 950 and 951:

Equations (22.423) are usually writ

- Page 952 and 953:

3. As the amplitude reaches the top

- Page 954 and 955:

Shallow Spherical Shells and Plates

- Page 956 and 957:

22.20 L. Cremer, M. Heckl: Structur

- Page 958 and 959:

Noise Noise is discussed in terms o

- Page 960 and 961:

where the overbars represent time a

- Page 962 and 963:

Typical outdoor setting A-weighted

- Page 964 and 965:

90 dB(A)” is widely used, and imp

- Page 966 and 967:

Microphone, amplifier and A/D conve

- Page 968 and 969:

When each segment of the measuremen

- Page 970 and 971:

found from � LW = Lp + 10 log A +

- Page 972 and 973:

surement method is the ultimate use

- Page 974 and 975:

An intensity analyzer is more compl

- Page 976 and 977:

23.2.5 Criteria for Noise Emissions

- Page 978 and 979:

Table 23.5 Table of limit values fr

- Page 980 and 981: a) Air flows freely to rotor Weak t

- Page 982 and 983: Static efficiency normalized to its

- Page 984 and 985: ful applications. Good results are

- Page 986 and 987: Table 23.8 Crossover speeds for var

- Page 988 and 989: Reduction of airplane engine noise

- Page 990 and 991: A variety of materials are used to

- Page 992 and 993: ∆LF (dB) 0 -10 -20 α -30 0.05 0.

- Page 994 and 995: Absorption coefficient 1.0 0.8 0.6

- Page 996 and 997: high enough that there is little so

- Page 998 and 999: 23.4.4 Criteria for Noise Immission

- Page 1000 and 1001: Table 23.10 (cont.) Some features o

- Page 1002 and 1003: Noise 23.4 Noise and the Receiver 1

- Page 1004 and 1005: view of administrative procedures r

- Page 1006 and 1007: provides recommendations for a foll

- Page 1008 and 1009: sound power levels of noise sources

- Page 1010 and 1011: 23.68 ISO: ISO 9296:1988 Acoustics

- Page 1012 and 1013: in impedance tubes - Part 2: Transf

- Page 1014 and 1015: 23.194 Commission of the European C

- Page 1016 and 1017: 1022 Part H Engineering Acoustics P

- Page 1018 and 1019: 1024 Part H Engineering Acoustics P

- Page 1020 and 1021: 1026 Part H Engineering Acoustics P

- Page 1022 and 1023: 1028 Part H Engineering Acoustics P

- Page 1024 and 1025: 1030 Part H Engineering Acoustics P

- Page 1026 and 1027: 1032 Part H Engineering Acoustics P

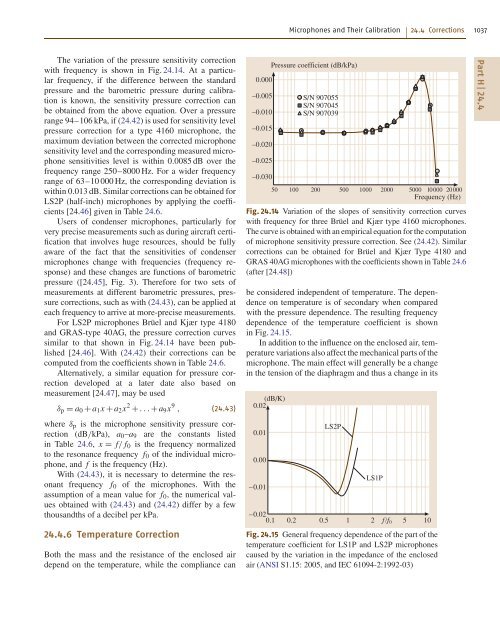

- Page 1028 and 1029: 1034 Part H Engineering Acoustics P

- Page 1032 and 1033: 1038 Part H Engineering Acoustics P

- Page 1034 and 1035: 1040 Part H Engineering Acoustics P

- Page 1036 and 1037: 1042 Part H Engineering Acoustics P

- Page 1038 and 1039: 1044 Part H Engineering Acoustics P

- Page 1040 and 1041: 1046 Part H Engineering Acoustics P

- Page 1042 and 1043: 1048 Part H Engineering Acoustics P

- Page 1044 and 1045: 1050 Part H Engineering Acoustics P

- Page 1046 and 1047: Sound 25. Intens Sound Intensity So

- Page 1048 and 1049: Under such conditions the intensity

- Page 1050 and 1051: a) Pressure and particle velocity 0

- Page 1052 and 1053: τ is a dummy time variable. The ca

- Page 1054 and 1055: Error in intensity (dB) 5 0 -5 -10

- Page 1056 and 1057: 8 7 6 5 4 3 2 1 0 -1 -2 -3 Error du

- Page 1058 and 1059: crophones are calibrated with a pis

- Page 1060 and 1061: Sound power level (dB re 1 pW) 72 7

- Page 1062 and 1063: it is relatively straightforward si

- Page 1064 and 1065: intensity normal to the source. Thi

- Page 1066 and 1067: 25.9 W. Maysenhölder: The reactive

- Page 1068 and 1069: 25.77 ISO: ISO 11205 Acoustics - No

- Page 1070 and 1071: 1078 Part H Engineering Acoustics P

- Page 1072 and 1073: 1080 Part H Engineering Acoustics P

- Page 1074 and 1075: 1082 Part H Engineering Acoustics P

- Page 1076 and 1077: 1084 Part H Engineering Acoustics P

- Page 1078 and 1079: 1086 Part H Engineering Acoustics P

- Page 1080 and 1081:

1088 Part H Engineering Acoustics P

- Page 1082 and 1083:

1090 Part H Engineering Acoustics P

- Page 1084 and 1085:

1092 Part H Engineering Acoustics P

- Page 1086 and 1087:

1094 Part H Engineering Acoustics P

- Page 1088 and 1089:

1096 Part H Engineering Acoustics P

- Page 1090 and 1091:

1098 Part H Engineering Acoustics P

- Page 1092 and 1093:

Optical 27. Optical Methods Metho f

- Page 1094 and 1095:

course also present in ordinary hol

- Page 1096 and 1097:

Optical Methods for Acoustics and V

- Page 1098 and 1099:

Optical Methods for Acoustics and V

- Page 1100 and 1101:

Optical Methods for Acoustics and V

- Page 1102 and 1103:

50 100 150 200 250 300 350 400 450

- Page 1104 and 1105:

a) b) Optical Methods for Acoustics

- Page 1106 and 1107:

nm 1000 0 -1000 150 y (mm) 100 50 O

- Page 1108 and 1109:

Optical Methods for Acoustics and V

- Page 1110 and 1111:

Optical Methods for Acoustics and V

- Page 1112 and 1113:

Laser Optical Methods for Acoustics

- Page 1114 and 1115:

References 27.1 E.F.F. Chladni: Die

- Page 1116 and 1117:

27.75 E.-L.Johansson, L. Benckert,

- Page 1118 and 1119:

1128 Part H Engineering Acoustics P

- Page 1120 and 1121:

1130 Part H Engineering Acoustics P

- Page 1122 and 1123:

1132 Part H Engineering Acoustics P

- Page 1124 and 1125:

1134 Part H Engineering Acoustics P

- Page 1126 and 1127:

1136 Part H Engineering Acoustics P

- Page 1128 and 1129:

1138 Part H Engineering Acoustics P

- Page 1130 and 1131:

About the Authors Iskander Akhatov

- Page 1132 and 1133:

Neville H. Fletcher Chapter F.19 Au

- Page 1134 and 1135:

Brian C. J. Moore Chapter D.13 Univ

- Page 1136 and 1137:

Detailed Contents List of Abbreviat

- Page 1138 and 1139:

3.8.3 Acoustic Power ..............

- Page 1140 and 1141:

4.8.3 Typical Speed of Sound Profil

- Page 1142 and 1143:

7.3 Engines .......................

- Page 1144 and 1145:

10 Concert Hall Acoustics Based on

- Page 1146 and 1147:

13.4 Temporal Processing in the Aud

- Page 1148 and 1149:

15.2.5 String-Bridge-Body Coupling

- Page 1150 and 1151:

19.6 Birds ........................

- Page 1152 and 1153:

22.4.5 Combinations of Elementary S

- Page 1154 and 1155:

24.8 Overall View on Microphone Cal

- Page 1156 and 1157:

Subject Index 3 dB bandwidth 463 A

- Page 1158 and 1159:

British Medical Ultrasound Society

- Page 1160 and 1161:

electric circuit analogues - acoust

- Page 1162 and 1163:

hyperspeech 703 hypospeech 703 I IA

- Page 1164 and 1165:

- participation factors 909 - stiff

- Page 1166 and 1167:

- musical instruments 541 - musical

- Page 1168 and 1169:

- nonlinear vibrations 957 - plate

- Page 1170 and 1171:

subjective preference theory 353 su