- Page 2 and 3: HANDBOOK OF MODERN SENSORS PHYSICS,

- Page 4 and 5: HANDBOOK OF MODERN SENSORS PHYSICS,

- Page 6 and 7: To the memory of my father

- Page 8 and 9: Preface Seven years have passed sin

- Page 10 and 11: Contents Preface ..................

- Page 12 and 13: Contents XI 4.5 Lenses ............

- Page 14 and 15: Contents XIII 7.7.1 Micropower Impu

- Page 16 and 17: Contents XV 15 Radiation Detectors

- Page 18 and 19: Contents XVII Table A.9 Physical Pr

- Page 20 and 21: 1 Data Acquisition “It’s as lar

- Page 22 and 23: 1.1 Sensors, Signals, and Systems 3

- Page 24 and 25: 1.1 Sensors, Signals, and Systems 5

- Page 26 and 27: 1.2 Sensor Classification 7 oscillo

- Page 28 and 29: 1.3 Units of Measurements 9 Table 1

- Page 30 and 31: Table 1.7. SI Basic Units Reference

- Page 32 and 33: 2 Sensor Characteristics “O, what

- Page 34 and 35: 2.2 Span (Full-Scale Input) 15 Fig.

- Page 36 and 37: 2.4 Accuracy 17 2.4 Accuracy Avery

- Page 38 and 39: 2.6 Calibration Error 19 To compute

- Page 40 and 41: 2.8 Nonlinearity 21 Fig. 2.4. Trans

- Page 42 and 43: 2.12 Resolution 23 (A) (B) Fig. 2.7

- Page 44 and 45: 2.16 Dynamic Characteristics 25 2.1

- Page 46 and 47: 2.16 Dynamic Characteristics 27 Sub

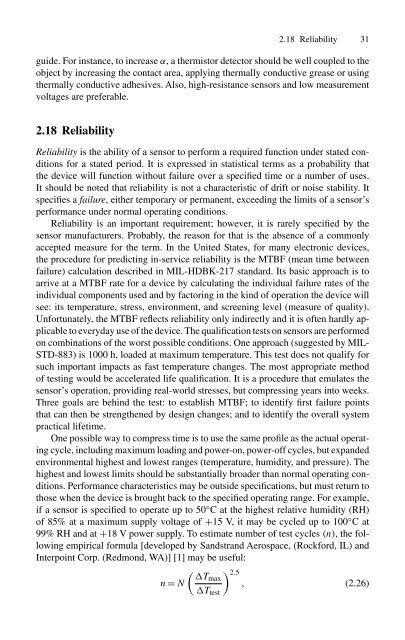

- Page 48 and 49: 2.17 Environmental Factors 29 2.17

- Page 52 and 53: 2.20 Uncertainty 33 • Thermal sho

- Page 54 and 55: Table 2.2. Uncertainty Budget for T

- Page 56 and 57: 3 Physical Principles of Sensing

- Page 58 and 59: 3.1 Electric Charges, Fields, and P

- Page 60 and 61: 3.1 Electric Charges, Fields, and P

- Page 62 and 63: 3.1 Electric Charges, Fields, and P

- Page 64 and 65: 3.2 Capacitance 45 The capacitor ma

- Page 66 and 67: 3.2 Capacitance 47 (A) (B) Fig. 3.6

- Page 68 and 69: 3.2 Capacitance 49 h 0 (A) (B) Fig.

- Page 70 and 71: 3.3 Magnetism 51 N S S N (A) (B) Fi

- Page 72 and 73: 3.3 Magnetism 53 electric charge ca

- Page 74 and 75: 3.3 Magnetism 55 3.3.3 Toroid Anoth

- Page 76 and 77: 3.4 Induction 57 • Changing the o

- Page 78 and 79: 3.5 Resistance 59 Fig. 3.16. Voltag

- Page 80 and 81: 3.5 Resistance 61 For pure resistan

- Page 82 and 83: 3.5 Resistance 63 resistor) and the

- Page 84 and 85: 3.5 Resistance 65 Fig. 3.19. Strain

- Page 86 and 87: 3.6 Piezoelectric Effect 67 (A) (B)

- Page 88 and 89: 3.6 Piezoelectric Effect 69 Another

- Page 90 and 91: 3.6 Piezoelectric Effect 71 Another

- Page 92 and 93: 3.6 Piezoelectric Effect 73 absorpt

- Page 94 and 95: 3.6 Piezoelectric Effect 75 that en

- Page 96 and 97: 3.7 Pyroelectric Effect 77 circuit

- Page 98 and 99: 3.7 Pyroelectric Effect 79 through

- Page 100 and 101:

3.7 Pyroelectric Effect 81 Fig. 3.2

- Page 102 and 103:

3.8 Hall Effect 83 Fig. 3.30. Hall

- Page 104 and 105:

Table 3.2. Typical Characteristics

- Page 106 and 107:

3.9 Seebeck and Peltier Effects 87

- Page 108 and 109:

3.9 Seebeck and Peltier Effects 89

- Page 110 and 111:

3.9 Seebeck and Peltier Effects 91

- Page 112 and 113:

3.10 Sound Waves 93 If we consider

- Page 114 and 115:

3.11 Temperature and Thermal Proper

- Page 116 and 117:

3.11 Temperature and Thermal Proper

- Page 118 and 119:

3.12 Heat Transfer 99 to about 35

- Page 120 and 121:

3.12 Heat Transfer 101 (A) (B) Fig.

- Page 122 and 123:

3.12 Heat Transfer 103 Fig. 3.41. S

- Page 124 and 125:

3.12 Heat Transfer 105 Fig. 3.42. S

- Page 126 and 127:

3.12 Heat Transfer 107 Fig. 3.44. W

- Page 128 and 129:

3.12 Heat Transfer 109 (A) (B) Fig.

- Page 130 and 131:

3.13 Light 111 [38] whose emissivit

- Page 132 and 133:

3.14 Dynamic Models of Sensor Eleme

- Page 134 and 135:

3.14 Dynamic Models of Sensor Eleme

- Page 136 and 137:

3.14 Dynamic Models of Sensor Eleme

- Page 138 and 139:

References 119 specified and three

- Page 140 and 141:

References 121 34. Thomson, W. On t

- Page 142 and 143:

124 4 Optical Components of Sensors

- Page 144 and 145:

126 4 Optical Components of Sensors

- Page 146 and 147:

128 4 Optical Components of Sensors

- Page 148 and 149:

130 4 Optical Components of Sensors

- Page 150 and 151:

132 4 Optical Components of Sensors

- Page 152 and 153:

134 4 Optical Components of Sensors

- Page 154 and 155:

136 4 Optical Components of Sensors

- Page 156 and 157:

138 4 Optical Components of Sensors

- Page 158 and 159:

140 4 Optical Components of Sensors

- Page 160 and 161:

142 4 Optical Components of Sensors

- Page 162 and 163:

144 4 Optical Components of Sensors

- Page 164 and 165:

146 4 Optical Components of Sensors

- Page 166 and 167:

148 4 Optical Components of Sensors

- Page 168 and 169:

150 Optical Components of Sensors 1

- Page 170 and 171:

5 Interface Electronic Circuits 5.1

- Page 172 and 173:

5.1 Input Characteristics of Interf

- Page 174 and 175:

5.1 Input Characteristics of Interf

- Page 176 and 177:

5.2 Amplifiers 157 (A) (B) Fig. 5.5

- Page 178 and 179:

5.2 Amplifiers 159 Fig. 5.7. Voltag

- Page 180 and 181:

5.2 Amplifiers 161 (A) (B) Fig. 5.9

- Page 182 and 183:

5.2 Amplifiers 163 Fig. 5.11. An eq

- Page 184 and 185:

5.3 Excitation Circuits 165 5.3.1 C

- Page 186 and 187:

5.3 Excitation Circuits 167 (A) (B)

- Page 188 and 189:

5.3 Excitation Circuits 169 Fig. 5.

- Page 190 and 191:

5.3 Excitation Circuits 171 atures.

- Page 192 and 193:

5.3 Excitation Circuits 173 (A) (B)

- Page 194 and 195:

5.4 Analog-to-Digital Converters 17

- Page 196 and 197:

Table 5.2. Binary Bit Weights and R

- Page 198 and 199:

5.4 Analog-to-Digital Converters 17

- Page 200 and 201:

5.4 Analog-to-Digital Converters 18

- Page 202 and 203:

5.4 Analog-to-Digital Converters 18

- Page 204 and 205:

5.4 Analog-to-Digital Converters 18

- Page 206 and 207:

5.5 Direct Digitization and Process

- Page 208 and 209:

5.5 Direct Digitization and Process

- Page 210 and 211:

5.6 Ratiometric Circuits 191 (A) (B

- Page 212 and 213:

5.7 Bridge Circuits 193 determine t

- Page 214 and 215:

5.7 Bridge Circuits 195 Fig. 5.38.

- Page 216 and 217:

5.7 Bridge Circuits 197 Fig. 5.39.

- Page 218 and 219:

It can be solved for the temperatur

- Page 220 and 221:

5.8 Data Transmission 201 (A) (B) (

- Page 222 and 223:

5.8 Data Transmission 203 wire meth

- Page 224 and 225:

5.9 Noise in Sensors and Circuits 2

- Page 226 and 227:

5.9 Noise in Sensors and Circuits 2

- Page 228 and 229:

5.9 Noise in Sensors and Circuits 2

- Page 230 and 231:

5.9 Noise in Sensors and Circuits 2

- Page 232 and 233:

5.9 Noise in Sensors and Circuits 2

- Page 234 and 235:

5.9 Noise in Sensors and Circuits 2

- Page 236 and 237:

5.9 Noise in Sensors and Circuits 2

- Page 238 and 239:

5.9 Noise in Sensors and Circuits 2

- Page 240 and 241:

5.9 Noise in Sensors and Circuits 2

- Page 242 and 243:

5.10 Batteries for Low Power Sensor

- Page 244 and 245:

References 225 nickel-metal hydrate

- Page 246 and 247:

6 Occupancy and Motion Detectors Se

- Page 248 and 249:

6.2 Microwave Motion Detectors 229

- Page 250 and 251:

6.2 Microwave Motion Detectors 231

- Page 252 and 253:

6.3 Capacitive Occupancy Detectors

- Page 254 and 255:

6.3 Capacitive Occupancy Detectors

- Page 256 and 257:

6.4 Triboelectric Detectors 237 6.4

- Page 258 and 259:

6.5 Optoelectronic Motion Detectors

- Page 260 and 261:

6.5 Optoelectronic Motion Detectors

- Page 262 and 263:

and the facet pitch is 6.5 Optoelec

- Page 264 and 265:

6.5 Optoelectronic Motion Detectors

- Page 266 and 267:

6.5 Optoelectronic Motion Detectors

- Page 268 and 269:

6.5 Optoelectronic Motion Detectors

- Page 270 and 271:

References 251 Fig. 6.17. Calculate

- Page 272 and 273:

7 Position, Displacement, and Level

- Page 274 and 275:

7.1 Potentiometric Sensors 255 (A)

- Page 276 and 277:

7.2 Gravitational Sensors 257 (A) (

- Page 278 and 279:

7.3 Capacitive Sensors 259 (A) (B)

- Page 280 and 281:

7.3 Capacitive Sensors 261 Fig. 7.7

- Page 282 and 283:

7.4 Inductive and Magnetic Sensors

- Page 284 and 285:

7.4 Inductive and Magnetic Sensors

- Page 286 and 287:

7.4 Inductive and Magnetic Sensors

- Page 288 and 289:

7.4 Inductive and Magnetic Sensors

- Page 290 and 291:

7.4 Inductive and Magnetic Sensors

- Page 292 and 293:

7.4 Inductive and Magnetic Sensors

- Page 294 and 295:

7.5 Optical Sensors 275 Therefore,

- Page 296 and 297:

7.5 Optical Sensors 277 (A) (B) (C)

- Page 298 and 299:

7.5 Optical Sensors 279 (A) (B) Fig

- Page 300 and 301:

7.5 Optical Sensors 281 Fig. 7.32.

- Page 302 and 303:

7.5 Optical Sensors 283 (A) (B) (C)

- Page 304 and 305:

7.5 Optical Sensors 285 is proporti

- Page 306 and 307:

7.6 Ultrasonic Sensors 287 (A) (B)

- Page 308 and 309:

7.7 Radar Sensors 289 (A) (B) Fig.

- Page 310 and 311:

7.7 Radar Sensors 291 (A) (B) Fig.

- Page 312 and 313:

7.8 Thickness and Level Sensors 293

- Page 314 and 315:

7.8 Thickness and Level Sensors 295

- Page 316 and 317:

7.8 Thickness and Level Sensors 297

- Page 318 and 319:

References 299 8. Dakin, J. P., Wad

- Page 320 and 321:

8 Velocity and Acceleration Acceler

- Page 322 and 323:

8.1 Accelerometer Characteristics 3

- Page 324 and 325:

8.2 Capacitive Accelerometers 305 a

- Page 326 and 327:

8.3 Piezoresistive Accelerometers 3

- Page 328 and 329:

8.5 Thermal Accelerometers 309 Fig.

- Page 330 and 331:

8.5 Thermal Accelerometers 311 forc

- Page 332 and 333:

8.6 Gyroscopes 313 8.6 Gyroscopes N

- Page 334 and 335:

8.6 Gyroscopes 315 (A) (B) Fig. 8.1

- Page 336 and 337:

8.6 Gyroscopes 317 Products Company

- Page 338 and 339:

8.7 Piezoelectric Cables 319 (A) (B

- Page 340 and 341:

References 321 (A) (B) Fig. 8.16.Ap

- Page 342 and 343:

9 Force, Strain, and Tactile Sensor

- Page 344 and 345:

9.1 Strain Gauges 325 (A) (B) Fig.

- Page 346 and 347:

9.2 Tactile Sensors 327 9.2 Tactile

- Page 348 and 349:

9.2 Tactile Sensors 329 (A) (B) Fig

- Page 350 and 351:

9.2 Tactile Sensors 331 Fig. 9.7. P

- Page 352 and 353:

9.2 Tactile Sensors 333 Fig. 9.9. T

- Page 354 and 355:

9.3 Piezoelectric Force Sensors 335

- Page 356 and 357:

References 337 14. Karrer, E. and L

- Page 358 and 359:

10 Pressure Sensors “To learn som

- Page 360 and 361:

10.3 Mercury Pressure Sensor 341 1

- Page 362 and 363:

10.4 Bellows, Membranes, and Thin P

- Page 364 and 365:

10.5 Piezoresistive Sensors 345 Fig

- Page 366 and 367:

10.5 Piezoresistive Sensors 347 bri

- Page 368 and 369:

10.6 Capacitive Sensors 349 (A) (B)

- Page 370 and 371:

10.7 VRP Sensors 351 (A) (B) Fig. 1

- Page 372 and 373:

10.8 Optoelectronic Sensors 353 Fig

- Page 374 and 375:

10.9 Vacuum Sensors 355 (A) (B) Fig

- Page 376 and 377:

References 357 (A) (B) (C) Fig. 10.

- Page 378 and 379:

11 Flow Sensors It’s a simple tas

- Page 380 and 381:

11.2 Pressure Gradient Technique 36

- Page 382 and 383:

11.3 Thermal Transport Sensors 363

- Page 384 and 385:

11.3 Thermal Transport Sensors 365

- Page 386 and 387:

11.4 Ultrasonic Sensors 367 A senso

- Page 388 and 389:

11.4 Ultrasonic Sensors 369 Fig. 11

- Page 390 and 391:

induced in the liquid. The magnitud

- Page 392 and 393:

11.6 Microflow Sensors 373 (A) (B)

- Page 394 and 395:

11.7 Breeze Sensor 375 (A) (B) Fig.

- Page 396 and 397:

11.9 Drag Force Flow Sensors 377 Wi

- Page 398 and 399:

References 379 11. Philip-Chandy, R

- Page 400 and 401:

12 Acoustic Sensors “Your ears wi

- Page 402 and 403:

12.3 Fiber-Optic Microphone 383 (A)

- Page 404 and 405:

12.4 Piezoelectric Microphones 385

- Page 406 and 407:

12.5 Electret Microphones 387 Fig.

- Page 408 and 409:

12.6 Solid-State Acoustic Detectors

- Page 410 and 411:

References 391 References 1. Hohm,

- Page 412 and 413:

13 Humidity and Moisture Sensors 13

- Page 414 and 415:

13.1 Concept of Humidity 395 Table

- Page 416 and 417:

13.2 Capacitive Sensors 397 Fig. 13

- Page 418 and 419:

13.3 Electrical Conductivity Sensor

- Page 420 and 421:

13.4 Thermal Conductivity Sensor 40

- Page 422 and 423:

13.6 Oscillating Hygrometer 403 chi

- Page 424 and 425:

References 405 9. Jachowicz, R. S.

- Page 426 and 427:

14 Light Detectors “There is noth

- Page 428 and 429:

14.1 Introduction 409 Table 14.1. B

- Page 430 and 431:

14.2 Photodiodes 411 Maximum revers

- Page 432 and 433:

14.2 Photodiodes 413 when i = 0), w

- Page 434 and 435:

14.2 Photodiodes 415 (A) (B) (C) Fi

- Page 436 and 437:

14.2 Photodiodes 417 Fig. 14.9. Res

- Page 438 and 439:

14.3 Phototransistor 419 Fig. 14.12

- Page 440 and 441:

14.4 Photoresistors 421 (A) (B) Fig

- Page 442 and 443:

14.5 Cooled Detectors 423 (A) (B) F

- Page 444 and 445:

14.6 Thermal Detectors 425 Table 14

- Page 446 and 447:

14.6 Thermal Detectors 427 Fig. 14.

- Page 448 and 449:

Table 14.3. Typical Specifications

- Page 450 and 451:

14.6 Thermal Detectors 431 A dual e

- Page 452 and 453:

14.6 Thermal Detectors 433 Fig. 14.

- Page 454 and 455:

14.6 Thermal Detectors 435 (A) (B)

- Page 456 and 457:

14.6 Thermal Detectors 437 Section

- Page 458 and 459:

14.7 Gas Flame Detectors 439 P = V

- Page 460 and 461:

References 441 housing assures wide

- Page 462 and 463:

15 Radiation Detectors Figure 3.41

- Page 464 and 465:

15.1 Scintillating Detectors 445 Fi

- Page 466 and 467:

15.2 Ionization Detectors 447 emitt

- Page 468 and 469:

15.2 Ionization Detectors 449 Fig.

- Page 470 and 471:

15.2 Ionization Detectors 451 parti

- Page 472 and 473:

15.2 Ionization Detectors 453 There

- Page 474 and 475:

References 455 the pure intrinsic t

- Page 476 and 477:

16 Temperature Sensors When a scien

- Page 478 and 479:

16 Temperature Sensors 459 from whi

- Page 480 and 481:

16.1 Thermoresistive Sensors 461 2.

- Page 482 and 483:

16.1 Thermoresistive Sensors 463 Ta

- Page 484 and 485:

16.1 Thermoresistive Sensors 465 Fi

- Page 486 and 487:

16.1 Thermoresistive Sensors 467 pr

- Page 488 and 489:

16.1 Thermoresistive Sensors 469 Fi

- Page 490 and 491:

16.1 Thermoresistive Sensors 471 Fi

- Page 492 and 493:

16.1 Thermoresistive Sensors 473 Fi

- Page 494 and 495:

16.1 Thermoresistive Sensors 475 (m

- Page 496 and 497:

16.1 Thermoresistive Sensors 477 Fi

- Page 498 and 499:

16.1 Thermoresistive Sensors 479 Fi

- Page 500 and 501:

16.2 Thermoelectric Contact Sensors

- Page 502 and 503:

16.2 Thermoelectric Contact Sensors

- Page 504 and 505:

16.2 Thermoelectric Contact Sensors

- Page 506 and 507:

16.2 Thermoelectric Contact Sensors

- Page 508 and 509:

16.3 Semiconductor P-N Junction Sen

- Page 510 and 511:

16.4 Optical Temperature Sensors 49

- Page 512 and 513:

16.4 Optical Temperature Sensors 49

- Page 514 and 515:

16.5 Acoustic Temperature Sensor 49

- Page 516 and 517:

References 497 plate—the so-calle

- Page 518 and 519:

17 Chemical Sensors 1 Chemical sens

- Page 520 and 521:

17.3 Classification of Chemical-Sen

- Page 522 and 523:

17.4 Direct Sensors 503 17.4 Direct

- Page 524 and 525:

17.4 Direct Sensors 505 voltage e.

- Page 526 and 527:

17.4 Direct Sensors 507 This reacti

- Page 528 and 529:

17.4 Direct Sensors 509 (A) (B) Fig

- Page 530 and 531:

17.4 Direct Sensors 511 µm thick a

- Page 532 and 533:

17.5 Complex Sensors 513 Fig. 17.11

- Page 534 and 535:

17.5 Complex Sensors 515 Fig. 17.12

- Page 536 and 537:

17.5 Complex Sensors 517 frequency

- Page 538 and 539:

Table 17.1. SAW Chemical Sensors 17

- Page 540 and 541:

17.6 Chemical Sensors Versus Instru

- Page 542 and 543:

17.6 Chemical Sensors Versus Instru

- Page 544 and 545:

17.6 Chemical Sensors Versus Instru

- Page 546 and 547:

17.6 Chemical Sensors Versus Instru

- Page 548 and 549:

17.6 Chemical Sensors Versus Instru

- Page 550 and 551:

References 531 13. LaCourse, W.R. P

- Page 552 and 553:

18 Sensor Materials and Technologie

- Page 554 and 555:

18.1 Materials 535 etching is a key

- Page 556 and 557:

18.1 Materials 537 Fig. 18.3. The a

- Page 558 and 559:

18.1 Materials 539 The following is

- Page 560 and 561:

18.1 Materials 541 should be consid

- Page 562 and 563:

18.2 Surface Processing 543 sensor

- Page 564 and 565:

18.2 Surface Processing 545 On a co

- Page 566 and 567:

18.3 Nano-Technology 547 6000-Å la

- Page 568 and 569:

18.3 Nano-Technology 549 exposed to

- Page 570 and 571:

18.3 Nano-Technology 551 Fig. 18.10

- Page 572 and 573:

18.3 Nano-Technology 553 (A) (B) Fi

- Page 574 and 575:

References 555 Fig. 18.17. Bonding

- Page 576 and 577:

Appendix Table A.1. Chemical Symbol

- Page 578 and 579:

Table A.4. SI Conversion Multiples

- Page 580 and 581:

Table A.4 Continued Light cd/in. 2

- Page 582 and 583:

Table A.4 Continued Cup 2.36588 ×

- Page 584 and 585:

Appendix 565 Table A.7. Some Materi

- Page 586 and 587:

Appendix 567 Table A.11. Thermoelec

- Page 588 and 589:

Table A.14. Mechanical Properties o

- Page 590 and 591:

Appendix 571 Table A.18. Typical Em

- Page 592 and 593:

Table A.20. Characteristics of C-Zn

- Page 594 and 595:

Table A.23 Continued Manufacturer P

- Page 596 and 597:

Table A.25. Properties of Glasses S

- Page 598 and 599:

Index α-particles, 443 A/D, 175, 1

- Page 600 and 601:

Index 581 Coulomb’s law, 40 cross

- Page 602 and 603:

Index 583 H 2 O, 108 Hall, 82 Hall

- Page 604 and 605:

Index 585 occupancy sensors, 227 od

- Page 606 and 607:

Index 587 SAW, 75, 388, 404, 496, 5

- Page 608:

Index 589 velocity sensor, 302 vert