Masoneilan SVI II AP Installation and Maintenance ... - GE Energy

Masoneilan SVI II AP Installation and Maintenance ... - GE Energy

Masoneilan SVI II AP Installation and Maintenance ... - GE Energy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>GE</strong> Oil <strong>and</strong> Gas<br />

<strong>SVI</strong> <strong>II</strong> <strong>AP</strong> Instruction Manual<br />

Connecting the Tubing <strong>and</strong> Air Supply<br />

The last step in hardware installation for the <strong>SVI</strong> <strong>II</strong> <strong>AP</strong> is to connect the air supply to the<br />

positioner. This section describes the process for connecting the tubing <strong>and</strong> air supply to<br />

a single <strong>and</strong> double acting positioner.<br />

WARNING<br />

Isolate the valve from the process <strong>and</strong> disconnect air tubing<br />

from the positioner. Disconnect air fully to avoid injury or<br />

process damage.<br />

1. Install the tubing to the air supply port, S(arrow only for High Flow).<br />

2. For a single acting actuator - pipe the outbound air from the output pressure port (I)<br />

to the actuator (arrow only for High Flow).<br />

3. For a double acting actuator - pipe output pressure port one (I) for one side of the<br />

actuator <strong>and</strong> output pressure port two (<strong>II</strong>) for the other side of the actuator<br />

(arrow only for High Flow).<br />

4. Air supply:<br />

Supply pressure for single acting <strong>SVI</strong> <strong>II</strong> <strong>AP</strong> <strong>and</strong> <strong>AP</strong> High Flow:<br />

20 -100 psi (1.4 - 6.9 bar) (138 - 690 kPa)<br />

Supply pressure for double acting <strong>SVI</strong> <strong>II</strong> <strong>AP</strong>:<br />

25 - 150 psi (1.73 - 10.3 bar) (172 - 1030 kPa)<br />

Minimum tubing diameter 1⁄4" (6mm x 4mm)<br />

NOTE<br />

The <strong>SVI</strong> <strong>II</strong> <strong>AP</strong> Digital Valve Positioner is designed to operate<br />

with clean, dry, oil-free, instrument grade air to ANSI-ISA-57.3<br />

1975 (R1981) or ISA-S7.3-1975 (R1981) or with a sweet<br />

natural gas supply (<strong>SVI</strong> <strong>II</strong> <strong>AP</strong> models <strong>SVI</strong> <strong>II</strong> <strong>AP</strong>-2 through <strong>SVI</strong><br />

<strong>II</strong> <strong>AP</strong>-3).<br />

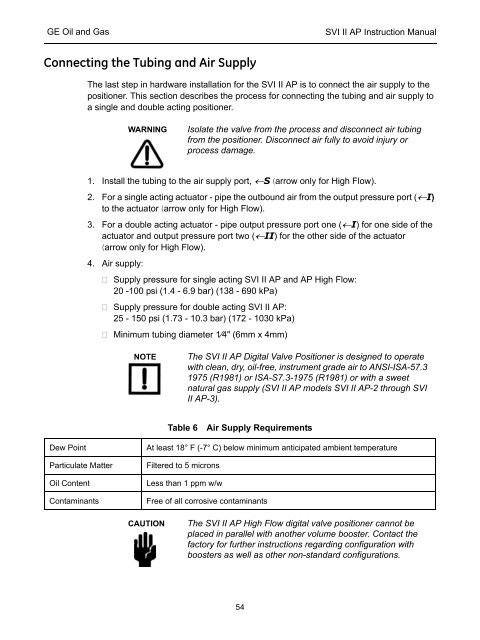

Table 6<br />

Air Supply Requirements<br />

Dew Point<br />

Particulate Matter<br />

Oil Content<br />

Contaminants<br />

At least 18° F (-7° C) below minimum anticipated ambient temperature<br />

Filtered to 5 microns<br />

Less than 1 ppm w/w<br />

Free of all corrosive contaminants<br />

CAUTION<br />

The <strong>SVI</strong> <strong>II</strong> <strong>AP</strong> High Flow digital valve positioner cannot be<br />

placed in parallel with another volume booster. Contact the<br />

factory for further instructions regarding configuration with<br />

boosters as well as other non-st<strong>and</strong>ard configurations.<br />

54