Proceedings of SerbiaTrib '13

Proceedings of SerbiaTrib '13

Proceedings of SerbiaTrib '13

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

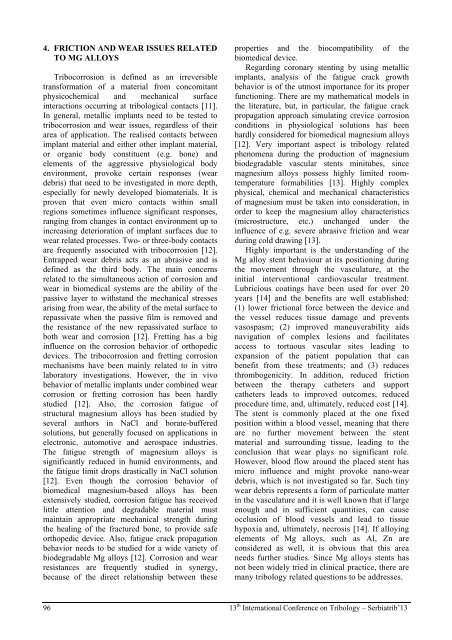

4. FRICTION AND WEAR ISSUES RELATEDTO MG ALLOYSTribocorrosion is defined as an irreversibletransformation <strong>of</strong> a material from concomitantphysicochemical and mechanical surfaceinteractions occurring at tribological contacts [11].In general, metallic implants need to be tested totribocorrosion and wear issues, regardless <strong>of</strong> theirarea <strong>of</strong> application. The realised contacts betweenimplant material and either other implant material,or organic body constituent (e.g. bone) andelements <strong>of</strong> the aggressive physiological bodyenvironment, provoke certain responses (weardebris) that need to be investigated in more depth,especially for newly developed biomaterials. It isproven that even micro contacts within smallregions sometimes influence significant responses,ranging from changes in contact environment up toincreasing deterioration <strong>of</strong> implant surfaces due towear related processes. Two- or three-body contactsare frequently associated with tribocorrosion [12].Entrapped wear debris acts as an abrasive and isdefined as the third body. The main concernsrelated to the simultaneous action <strong>of</strong> corrosion andwear in biomedical systems are the ability <strong>of</strong> thepassive layer to withstand the mechanical stressesarising from wear, the ability <strong>of</strong> the metal surface torepassivate when the passive film is removed andthe resistance <strong>of</strong> the new repassivated surface toboth wear and corrosion [12]. Fretting has a biginfluence on the corrosion behavior <strong>of</strong> orthopedicdevices. The tribocorrosion and fretting corrosionmechanisms have been mainly related to in vitrolaboratory investigations. However, the in vivobehavior <strong>of</strong> metallic implants under combined wearcorrosion or fretting corrosion has been hardlystudied [12]. Also, the corrosion fatigue <strong>of</strong>structural magnesium alloys has been studied byseveral authors in NaCl and borate-bufferedsolutions, but generally focused on applications inelectronic, automotive and aerospace industries.The fatigue strength <strong>of</strong> magnesium alloys issignificantly reduced in humid environments, andthe fatigue limit drops drastically in NaCl solution[12]. Even though the corrosion behavior <strong>of</strong>biomedical magnesium-based alloys has beenextensively studied, corrosion fatigue has receivedlittle attention and degradable material mustmaintain appropriate mechanical strength duringthe healing <strong>of</strong> the fractured bone, to provide safeorthopedic device. Also, fatigue crack propagationbehavior needs to be studied for a wide variety <strong>of</strong>biodegradable Mg alloys [12]. Corrosion and wearresistances are frequently studied in synergy,because <strong>of</strong> the direct relationship between theseproperties and the biocompatibility <strong>of</strong> thebiomedical device.Regarding coronary stenting by using metallicimplants, analysis <strong>of</strong> the fatigue crack growthbehavior is <strong>of</strong> the utmost importance for its properfunctioning. There are my mathematical models inthe literature, but, in particular, the fatigue crackpropagation approach simulating crevice corrosionconditions in physiological solutions has beenhardly considered for biomedical magnesium alloys[12]. Very important aspect is tribology relatedphenomena during the production <strong>of</strong> magnesiumbiodegradable vascular stents minitubes, sincemagnesium alloys possess highly limited roomtemperatureformabilities [13]. Highly complexphysical, chemical and mechanical characteristics<strong>of</strong> magnesium must be taken into consideration, inorder to keep the magnesium alloy characteristics(microstructure, etc.) unchanged under theinfluence <strong>of</strong> e.g. severe abrasive friction and wearduring cold drawing [13].Highly important is the understanding <strong>of</strong> theMg alloy stent behaviour at its positioning duringthe movement through the vasculature, at theinitial interventional cardiovascular treatment.Lubricious coatings have been used for over 20years [14] and the benefits are well established:(1) lower frictional force between the device andthe vessel reduces tissue damage and preventsvasospasm; (2) improved maneuverability aidsnavigation <strong>of</strong> complex lesions and facilitatesaccess to tortuous vascular sites leading toexpansion <strong>of</strong> the patient population that canbenefit from these treatments; and (3) reducesthrombogenicity. In addition, reduced frictionbetween the therapy catheters and supportcatheters leads to improved outcomes, reducedprocedure time, and, ultimately, reduced cost [14].The stent is commonly placed at the one fixedposition within a blood vessel, meaning that thereare no further movement between the stentmaterial and surrounding tissue, leading to theconclusion that wear plays no significant role.However, blood flow around the placed stent hasmicro influence and might provoke nano-weardebris, which is not investigated so far. Such tinywear debris represents a form <strong>of</strong> particulate matterin the vasculature and it is well known that if largeenough and in sufficient quantities, can causeocclusion <strong>of</strong> blood vessels and lead to tissuehypoxia and, ultimately, necrosis [14]. If alloyingelements <strong>of</strong> Mg alloys, such as Al, Zn areconsidered as well, it is obvious that this areaneeds further studies. Since Mg alloys stents hasnot been widely tried in clinical practice, there aremany tribology related questions to be addresses.96 13 th International Conference on Tribology – Serbiatrib’13