Engineering

Engineering

Engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2.5 Management report on on the Group Non-financial performance indicators indicators<br />

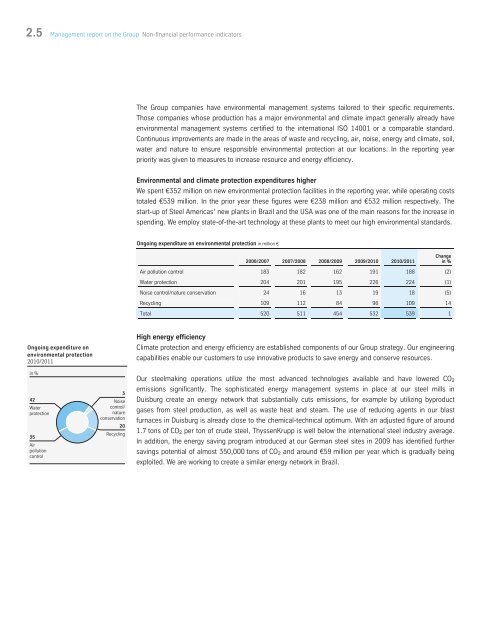

Ongoing expenditure on<br />

environmental protection<br />

2010/2011<br />

in %<br />

42<br />

Water<br />

protection<br />

35<br />

Air<br />

pollution<br />

control<br />

36<br />

3<br />

Noise<br />

control/<br />

nature<br />

conservation<br />

20<br />

Recycling<br />

The Group companies have environmental management systems tailored to their specific requirements.<br />

Those companies whose production has a major environmental and climate impact generally already have<br />

environmental management systems certified to the international ISO 14001 or a comparable standard.<br />

Continuous improvements are made in the areas of waste and recycling, air, noise, energy and climate, soil,<br />

water and nature to ensure responsible environmental protection at our locations. In the reporting year<br />

priority was given to measures to increase resource and energy efficiency.<br />

Environmental and climate protection expenditures higher<br />

We spent €352 million on new environmental protection facilities in the reporting year, while operating costs<br />

totaled €539 million. In the prior year these figures were €238 million and €532 million respectively. The<br />

start-up of Steel Americas’ new plants in Brazil and the USA was one of the main reasons for the increase in<br />

spending. We employ state-of-the-art technology at these plants to meet our high environmental standards.<br />

Ongoing expenditure on environmental protection in million €<br />

2006/2007 2007/2008 2008/2009 2009/2010 2010/2011<br />

100<br />

Change<br />

in %<br />

Air pollution control 183 182 162 191 188 (2)<br />

Water protection 204 201 195 226 224 (1)<br />

Noise control/nature conservation 24 16 13 19 18 (5)<br />

Recycling 109 112 84 96 109 14<br />

Total 520 511 454 532 539 1<br />

High energy efficiency<br />

Climate protection and energy efficiency are established components of our Group strategy. Our engineering<br />

capabilities enable our customers to use innovative products to save energy and conserve resources.<br />

Our steelmaking operations utilize the most advanced technologies available and have lowered CO2<br />

emissions significantly. The sophisticated energy management systems in place at our steel mills in<br />

Duisburg create an energy network that substantially cuts emissions, for example by utilizing byproduct<br />

gases from steel production, as well as waste heat and steam. The use of reducing agents in our blast<br />

furnaces in Duisburg is already close to the chemical-technical optimum. With an adjusted figure of around<br />

1.7 tons of CO2 per ton of crude steel, ThyssenKrupp is well below the international steel industry average.<br />

In addition, the energy saving program introduced at our German steel sites in 2009 has identified further<br />

savings potential of almost 350,000 tons of CO2 and around €59 million per year which is gradually being<br />

exploited. We are working to create a similar energy network in Brazil.