Operating Instruction - Frequency Inverter 230V / 400V ... - opis.cz

Operating Instruction - Frequency Inverter 230V / 400V ... - opis.cz

Operating Instruction - Frequency Inverter 230V / 400V ... - opis.cz

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

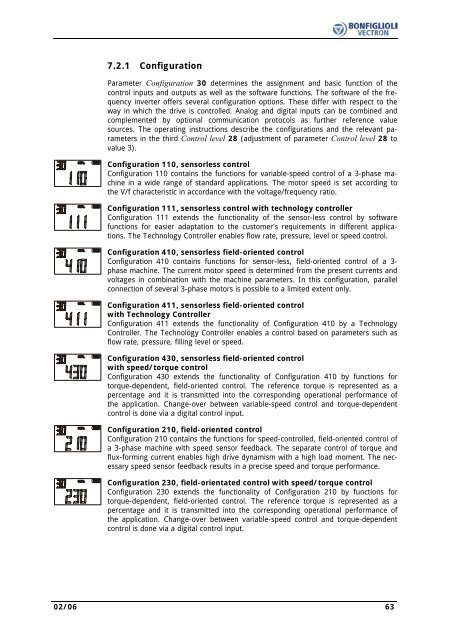

7.2.1 ConfigurationParameter Configuration 30 determines the assignment and basic function of thecontrol inputs and outputs as well as the software functions. The software of the frequencyinverter offers several configuration options. These differ with respect to theway in which the drive is controlled. Analog and digital inputs can be combined andcomplemented by optional communication protocols as further reference valuesources. The operating instructions describe the configurations and the relevant parametersin the third Control level 28 (adjustment of parameter Control level 28 tovalue 3).Configuration 110, sensorless controlConfiguration 110 contains the functions for variable-speed control of a 3-phase machinein a wide range of standard applications. The motor speed is set according tothe V/f characteristic in accordance with the voltage/frequency ratio.Configuration 111, sensorless control with technology controllerConfiguration 111 extends the functionality of the sensor-less control by softwarefunctions for easier adaptation to the customer's requirements in different applications.The Technology Controller enables flow rate, pressure, level or speed control.Configuration 410, sensorless field-oriented controlConfiguration 410 contains functions for sensor-less, field-oriented control of a 3-phase machine. The current motor speed is determined from the present currents andvoltages in combination with the machine parameters. In this configuration, parallelconnection of several 3-phase motors is possible to a limited extent only.Configuration 411, sensorless field-oriented controlwith Technology ControllerConfiguration 411 extends the functionality of Configuration 410 by a TechnologyController. The Technology Controller enables a control based on parameters such asflow rate, pressure, filling level or speed.Configuration 430, sensorless field-oriented controlwith speed/torque controlConfiguration 430 extends the functionality of Configuration 410 by functions fortorque-dependent, field-oriented control. The reference torque is represented as apercentage and it is transmitted into the corresponding operational performance ofthe application. Change-over between variable-speed control and torque-dependentcontrol is done via a digital control input.Configuration 210, field-oriented controlConfiguration 210 contains the functions for speed-controlled, field-oriented control ofa 3-phase machine with speed sensor feedback. The separate control of torque andflux-forming current enables high drive dynamism with a high load moment. The necessaryspeed sensor feedback results in a precise speed and torque performance.Configuration 230, field-orientated control with speed/torque controlConfiguration 230 extends the functionality of Configuration 210 by functions fortorque-dependent, field-oriented control. The reference torque is represented as apercentage and it is transmitted into the corresponding operational performance ofthe application. Change-over between variable-speed control and torque-dependentcontrol is done via a digital control input.02/06 63