Operating Instruction - Frequency Inverter 230V / 400V ... - opis.cz

Operating Instruction - Frequency Inverter 230V / 400V ... - opis.cz

Operating Instruction - Frequency Inverter 230V / 400V ... - opis.cz

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

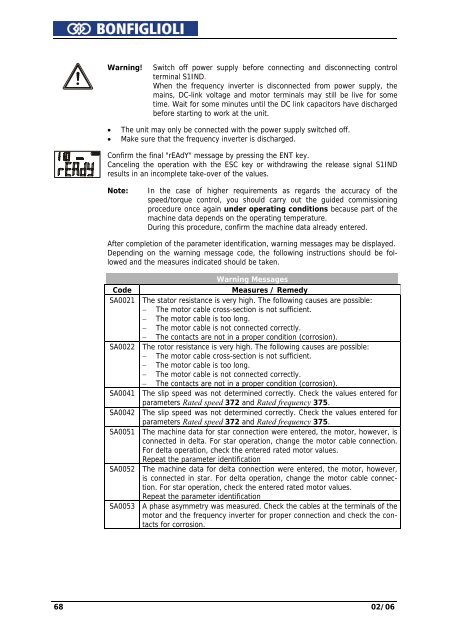

Warning!Switch off power supply before connecting and disconnecting controlterminal S1IND.When the frequency inverter is disconnected from power supply, themains, DC-link voltage and motor terminals may still be live for sometime. Wait for some minutes until the DC link capacitors have dischargedbefore starting to work at the unit.• The unit may only be connected with the power supply switched off.• Make sure that the frequency inverter is discharged.Confirm the final "rEAdY" message by pressing the ENT key.Canceling the operation with the ESC key or withdrawing the release signal S1INDresults in an incomplete take-over of the values.Note:In the case of higher requirements as regards the accuracy of thespeed/torque control, you should carry out the guided commissioningprocedure once again under operating conditions because part of themachine data depends on the operating temperature.During this procedure, confirm the machine data already entered.After completion of the parameter identification, warning messages may be displayed.Depending on the warning message code, the following instructions should be followedand the measures indicated should be taken.Warning MessagesCodeMeasures / RemedySA0021 The stator resistance is very high. The following causes are possible:− The motor cable cross-section is not sufficient.− The motor cable is too long.− The motor cable is not connected correctly.− The contacts are not in a proper condition (corrosion).SA0022 The rotor resistance is very high. The following causes are possible:− The motor cable cross-section is not sufficient.− The motor cable is too long.− The motor cable is not connected correctly.− The contacts are not in a proper condition (corrosion).SA0041 The slip speed was not determined correctly. Check the values entered forparameters Rated speed 372 and Rated frequency 375.SA0042 The slip speed was not determined correctly. Check the values entered forparameters Rated speed 372 and Rated frequency 375.SA0051 The machine data for star connection were entered, the motor, however, isconnected in delta. For star operation, change the motor cable connection.For delta operation, check the entered rated motor values.Repeat the parameter identificationSA0052 The machine data for delta connection were entered, the motor, however,is connected in star. For delta operation, change the motor cable connection.For star operation, check the entered rated motor values.Repeat the parameter identificationSA0053 A phase asymmetry was measured. Check the cables at the terminals of themotor and the frequency inverter for proper connection and check the contactsfor corrosion.68 02/06