Operating Instruction - Frequency Inverter 230V / 400V ... - opis.cz

Operating Instruction - Frequency Inverter 230V / 400V ... - opis.cz

Operating Instruction - Frequency Inverter 230V / 400V ... - opis.cz

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

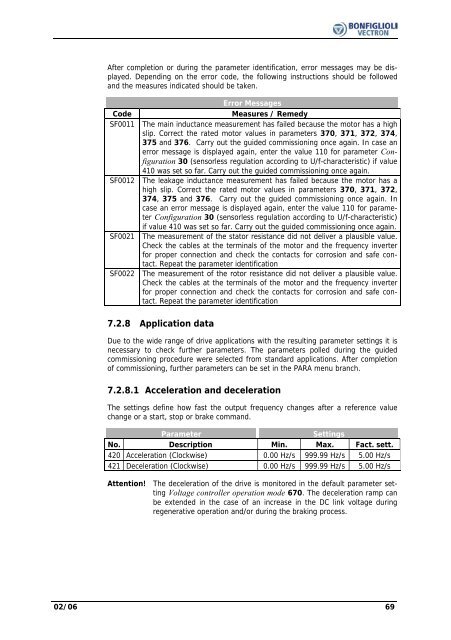

After completion or during the parameter identification, error messages may be displayed.Depending on the error code, the following instructions should be followedand the measures indicated should be taken.Error MessagesCodeMeasures / RemedySF0011 The main inductance measurement has failed because the motor has a highslip. Correct the rated motor values in parameters 370, 371, 372, 374,375 and 376. Carry out the guided commissioning once again. In case anerror message is displayed again, enter the value 110 for parameter Configuration30 (sensorless regulation according to U/f-characteristic) if value410 was set so far. Carry out the guided commissioning once again.SF0012 The leakage inductance measurement has failed because the motor has ahigh slip. Correct the rated motor values in parameters 370, 371, 372,374, 375 and 376. Carry out the guided commissioning once again. Incase an error message is displayed again, enter the value 110 for parameterConfiguration 30 (sensorless regulation according to U/f-characteristic)if value 410 was set so far. Carry out the guided commissioning once again.SF0021 The measurement of the stator resistance did not deliver a plausible value.Check the cables at the terminals of the motor and the frequency inverterfor proper connection and check the contacts for corrosion and safe contact.Repeat the parameter identificationSF0022 The measurement of the rotor resistance did not deliver a plausible value.Check the cables at the terminals of the motor and the frequency inverterfor proper connection and check the contacts for corrosion and safe contact.Repeat the parameter identification7.2.8 Application dataDue to the wide range of drive applications with the resulting parameter settings it isnecessary to check further parameters. The parameters polled during the guidedcommissioning procedure were selected from standard applications. After completionof commissioning, further parameters can be set in the PARA menu branch.7.2.8.1 Acceleration and decelerationThe settings define how fast the output frequency changes after a reference valuechange or a start, stop or brake command.ParameterSettingsNo. Description Min. Max. Fact. sett.420 Acceleration (Clockwise) 0.00 Hz/s 999.99 Hz/s 5.00 Hz/s421 Deceleration (Clockwise) 0.00 Hz/s 999.99 Hz/s 5.00 Hz/sAttention! The deceleration of the drive is monitored in the default parameter settingVoltage controller operation mode 670. The deceleration ramp canbe extended in the case of an increase in the DC link voltage duringregenerative operation and/or during the braking process.02/06 69