Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

• Enabling Integral Torque Limit Operation (L7-06 and L7-07)<br />

In Open Loop Vector control an integral operation can be applied to the torque limit function (P-control is<br />

standard). This improves the torque limit responsiveness and smoothes the torque limit operation. To enable<br />

the integral operation set parameter L7-07 to 1. The integral time constant can be set in parameter L7-06.<br />

•Setting Precautions<br />

• When the output torque reaches the torque limit, control and compensation of the motor speed is disabled<br />

to prevent the output torque from exceeding the torque limit. The torque limit has the priority.<br />

• The torque limit accuracy is ±5% at an output frequency of 10 Hz or above. When output frequency is<br />

lower than 10 Hz, the accuracy is lowered.<br />

Motor Overload Protection<br />

The motor can be protected from overload using the built-in electronic thermal overload relay function.<br />

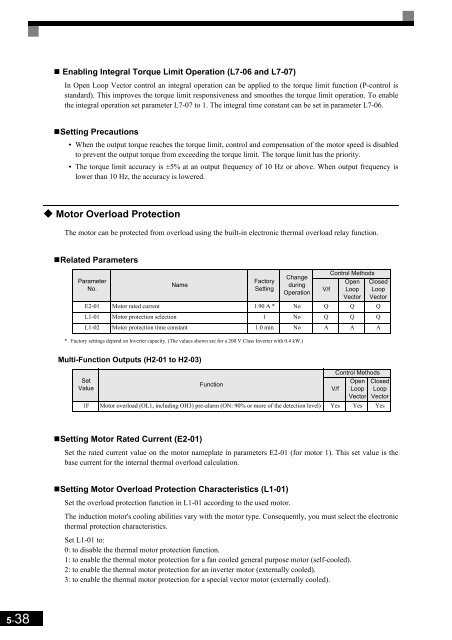

•Related Parameters<br />

Parameter<br />

No.<br />

Name<br />

Factory<br />

Setting<br />

Change<br />

during<br />

Operation<br />

V/f<br />

Control Methods<br />

Open<br />

Loop<br />

Vector<br />

E2-01 Motor rated current 1.90 A * No Q Q Q<br />

L1-01 Motor protection selection 1 No Q Q Q<br />

L1-02 Motor protection time constant 1.0 min No A A A<br />

Closed<br />

Loop<br />

Vector<br />

* Factory settings depend on Inverter capacity. (The values shown are for a 200 V Class Inverter with 0.4 kW.)<br />

Multi-Function Outputs (H2-01 to H2-03)<br />

Set<br />

Value<br />

Function<br />

V/f<br />

Control Methods<br />

Open<br />

Loop<br />

Vector<br />

Closed<br />

Loop<br />

Vector<br />

1F Motor overload (OL1, including OH3) pre-alarm (ON: 90% or more of the detection level) Yes Yes Yes<br />

•Setting Motor Rated Current (E2-01)<br />

Set the rated current value on the motor nameplate in parameters E2-01 (for motor 1). This set value is the<br />

base current for the internal thermal overload calculation.<br />

•Setting Motor Overload Protection Characteristics (L1-01)<br />

Set the overload protection function in L1-01 according to the used motor.<br />

The induction motor's cooling abilities vary with the motor type. Consequently, you must select the electronic<br />

thermal protection characteristics.<br />

Set L1-01 to:<br />

0: to disable the thermal motor protection function.<br />

1: to enable the thermal motor protection for a fan cooled general purpose motor (self-cooled).<br />

2: to enable the thermal motor protection for an inverter motor (externally cooled).<br />

3: to enable the thermal motor protection for a special vector motor (externally cooled).<br />

5-38