- Page 5 and 6:

PREFACEThe Tahoe Regional Planning

- Page 7 and 8:

TABLE OF CONTENTSPREFACE...........

- Page 9:

3.5.5 Stormwater Treatment ........

- Page 12 and 13:

6.3 Projects 1 to 5 Acres and all C

- Page 14 and 15:

8.10.5 Maintenance ................

- Page 16 and 17:

Table 8-4: Federal, State and Regio

- Page 18 and 19:

Figure 4.3-i: Vegetated Swale .....

- Page 20 and 21:

INTRODUCTIONPURPOSE AND USERS OF TH

- Page 22 and 23:

Lake Tahoe’s world renowned blue

- Page 24 and 25:

Urbanization in the Lake Tahoe wate

- Page 26 and 27:

50 percent of the light scattering

- Page 28 and 29:

Figure I-c: Impervious Cover versus

- Page 30 and 31:

Disconnected impervious areasdrain

- Page 32 and 33:

POLLUTANT EFFECT URBAN SOURCES ASSO

- Page 34 and 35:

BEST MANAGEMENT PRACTICESHistorical

- Page 36 and 37:

Table I-2: Differences in BMP Retro

- Page 38 and 39:

CHAPTER 1: URBAN HYDROLOGY1.1 PURPO

- Page 40 and 41:

Figure 1-a: Runoff ProcessesTRPA BM

- Page 42 and 43:

Although many urbanized areas face

- Page 44 and 45:

watersheds to make the necessary es

- Page 46 and 47:

Pollutant load estimates are typica

- Page 48 and 49:

differ from the following recommend

- Page 50 and 51:

Figure 1-b: Hydrologic Processes an

- Page 52 and 53:

1.3.3.2 NRCS BMP CALCULATION SPREAD

- Page 54 and 55:

1.3.3.3 RATIONAL METHODMODEL SUMMAR

- Page 56 and 57:

1.3.3.4 LOAD REDUCTION PLANNING TOO

- Page 58 and 59:

in HMS may be event-based or contin

- Page 60 and 61:

1.3.3.6 POLLUTANT LOAD REDUCTION MO

- Page 62 and 63:

AVAILABILITY AND SUPPORTING DOCUMEN

- Page 64 and 65:

TYPICAL LEVEL OF EFFORTHSPF and LSP

- Page 66 and 67:

few days to a week of time to revie

- Page 68 and 69:

USACE studies recommended use of th

- Page 70 and 71:

during the initial site visit, or c

- Page 72 and 73:

Figure 2-a: Soil Horizons• Depth

- Page 74 and 75:

Evidence of compacted and disturbed

- Page 76 and 77:

UNMAPPED ROCK OUTCROPS, STEEP SLOPE

- Page 78 and 79:

The primary pollutants of concern o

- Page 80 and 81:

On the map use an arrow to delineat

- Page 82 and 83:

2.2.3 ADDITIONAL DATA GATHERINGAfte

- Page 84 and 85:

and allowable uses. Baseline Land C

- Page 86:

topographic survey will be required

- Page 89:

Table 2-3: Basis of Capability Clas

- Page 92 and 93:

Keep your property lean, clean,and

- Page 94 and 95:

treatment. This will reduce the mai

- Page 96 and 97:

ponds, wetlands, lakes, manmade cha

- Page 98 and 99:

2.3.3.2 SOILS HYDROLOGIC REPORTThe

- Page 100 and 101:

CHAPTER 3: PERMANENT BMP PLANNINGAN

- Page 102 and 103:

STORMWATER TREATMENTRepresents BMPs

- Page 104 and 105:

Table 3-1: Waste Management and Mat

- Page 106 and 107:

D. STABILIZE STEEP DISTURBED SLOPES

- Page 108 and 109:

This infiltration trench collects s

- Page 110 and 111:

3.5 PROJECTS 1 TO 5 ACRES AND ALL C

- Page 112 and 113:

This Page Blank.TRPA BMP HandbookCH

- Page 114 and 115:

unnecessary turf areas and replace

- Page 116 and 117:

Table 3-5: Waste Management and Mat

- Page 118 and 119:

3.5.2.3 SOIL STABILIZATIONA. RESTOR

- Page 120 and 121:

Left: Dripline erosion below a deck

- Page 122 and 123:

Pervious concrete parking pad locat

- Page 124 and 125:

3.5.5 STORMWATER TREATMENT3.5.5.1 M

- Page 126 and 127:

3.6.1.1 JURISDICTIONThese projects

- Page 128 and 129:

to perform required inspection and

- Page 130 and 131:

3.8.2.4 SHARED ACCESS AND EASEMENTS

- Page 132 and 133:

3.8.2.8 STREAM ENVIRONMENT ZONES (S

- Page 134 and 135:

Sediment versus erosion:Suspended s

- Page 136 and 137:

CONTENTSCHAPTER 4: BMP TOOLKIT ....

- Page 138 and 139:

CHAPTER 4: BMP TOOLKIT4.1 HYDROLOGI

- Page 140 and 141:

4.1.1.1 PERVIOUS PAVEMENTAlternativ

- Page 142 and 143:

• Tree canopy overhead can decrea

- Page 144 and 145:

ate determined at the time of insta

- Page 146 and 147:

Figure 4.1-a: Pervious ConcreteTRPA

- Page 148 and 149:

4.1.1.2 INFILTRATION BASINAlternati

- Page 150 and 151:

groundwater, depths to restrictive

- Page 152 and 153:

Very few performance monitoring stu

- Page 154 and 155:

INSPECTION AND MAINTENANCE ACTIVITI

- Page 156 and 157:

4.1.1.3 INFILTRATION TRENCHAlternat

- Page 158 and 159:

• Consult the NRCS Tahoe Basin So

- Page 160 and 161:

• Alternative Method: Excavate th

- Page 162 and 163:

Figure 4.1-c: Infiltration TrenchTR

- Page 164 and 165:

Figure 4.1-e: Roof Dripline Planter

- Page 166 and 167:

4.1.1.4 SUBSURFACE INFILTRATION SYS

- Page 168:

percent void space compared to 40 p

- Page 171 and 172:

• Ensure the surrounding surface

- Page 174 and 175:

4.1.1.5 RAIN BARREL AND CISTERNAlte

- Page 176 and 177:

• Position the rain barrel or cis

- Page 178 and 179:

4.1.1.6 RAIN GARDENAlternative Name

- Page 180 and 181:

• To manage high flows, design a

- Page 182 and 183:

4.1.1.7 FILTER STRIPAlternative Nam

- Page 184 and 185:

• The top of the vegetated filter

- Page 186 and 187:

INSPECTION AND MAINTENANCE ACTIVITI

- Page 188 and 189:

Figure 4.1-i: Vegetated Filter Stri

- Page 190 and 191:

LIST OF FIGURESFigure 4.2-a: Slope

- Page 192 and 193:

Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 194 and 195:

• Obtain and use a road abrasive

- Page 196 and 197:

Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 198 and 199:

• Mechanical broom sweepers may a

- Page 200 and 201:

EFFECTIVENESS CONSIDERATIONSA signi

- Page 202 and 203:

for dry basins or infiltration basi

- Page 204 and 205:

• For unpaved snow storage areas

- Page 206 and 207:

Figure 4.2-a: Slope Stabilization A

- Page 208 and 209:

Disadvantages• Not always success

- Page 210 and 211:

• Bind together long live branch

- Page 212 and 213:

Brush Layering and MattingBrush lay

- Page 214 and 215:

Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 216 and 217:

Advantages• Reduces the erosion p

- Page 218 and 219:

Table 4.2-1: Terracing Inspection a

- Page 220 and 221:

Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 222 and 223:

Disadvantages• Can be complicated

- Page 224 and 225:

• Revegetate the backfilled bench

- Page 226 and 227:

Figure 4.2-d: Timber Retaining Wall

- Page 228 and 229:

Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 230 and 231:

Advantages• Versatile and applica

- Page 232 and 233:

Table 4.2-3: Riprap Inspection and

- Page 234 and 235:

Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 236 and 237:

educe the concentration of runoff,

- Page 238 and 239:

Figure 4.2-g: Slope Bottom BenchFig

- Page 240 and 241:

• Contour Furrows - relatively de

- Page 242 and 243:

Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 244 and 245:

APPLICABILITYAll roads, driveways,

- Page 246 and 247:

Stormwater runoff from a paved park

- Page 248 and 249:

Figure 4.2-k: Grading for Sheet Flo

- Page 250 and 251:

INORGANIC MULCH:• Areas where org

- Page 252 and 253:

• Stockpile and use existing orga

- Page 254 and 255:

Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 256 and 257:

The surface under the raised decksh

- Page 258 and 259:

Figure 4.2-l: Rock Armor - Elevated

- Page 260 and 261:

Clustered boulders used for parking

- Page 262 and 263:

Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 264 and 265:

Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 266 and 267:

• Helps to protect wildlife.• H

- Page 268 and 269:

EFFECTIVENESS CONSIDERATIONSA prope

- Page 270 and 271:

Improper storage of hazardous mater

- Page 272 and 273:

• Try to use the entire product b

- Page 274 and 275:

Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 276 and 277:

facilities must be equipped with ap

- Page 278 and 279:

Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 280 and 281:

• Dispose of it properly• Be a

- Page 282 and 283:

Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 284 and 285: Disadvantages• Additional resourc

- Page 286 and 287: • All hay, cubed hay, straw, mulc

- Page 288 and 289: • Sanitary sewer regulations gene

- Page 290 and 291: APPLICABILITYAll vehicles, includin

- Page 292 and 293: • Do not perform other vehicle or

- Page 294 and 295: LIST OF FIGURESFigure 4.3-a: Curb B

- Page 296 and 297: Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 298 and 299: APPLICABILITY• Culverts are appli

- Page 300 and 301: deterioration. The inspection crew

- Page 302 and 303: Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 304 and 305: APPLICABILITY• Curb and gutters a

- Page 306 and 307: INSTALLATION CONSIDERATIONS• Inst

- Page 308 and 309: Figure 4.3-b: Rolled CurbChapter 4:

- Page 310 and 311: Advantages• Prevents the discharg

- Page 312 and 313: Table 4.3-2: Storm Drain Inspection

- Page 314 and 315: Advantages• Prevents scour that m

- Page 316 and 317: Figure 4.3-c: Outlet ProtectionChap

- Page 318 and 319: Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 320 and 321: • The structure can be designed t

- Page 322 and 323: Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 324 and 325: INSTALLATION CONSIDERATIONS• Disc

- Page 326 and 327: Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 328 and 329: Advantages• Assists in the contro

- Page 330 and 331: Figure 4.3-e: Slotted Channel Drain

- Page 332 and 333: Advantages• May be less expensive

- Page 336 and 337: Chapter 4: BMP ToolkitTRPA BMP Hand

- Page 338 and 339: • Prevents property damage, slope

- Page 340 and 341: Figure 4.3-g: Subsurface DrainChapt

- Page 342 and 343: abrasives applied during the winter

- Page 344 and 345: Table 4.3-7: Rock Lined and Vegetat

- Page 346 and 347: Figure 4.3-i: Vegetated SwaleChapte

- Page 348 and 349: Check dams installed in water sprea

- Page 350 and 351: • Design check dams perpendicular

- Page 352 and 353: CONTENTS4.4 Stormwater Treatment ..

- Page 354 and 355: 4.4 STORMWATER TREATMENTThe primary

- Page 356 and 357: 4.4.1.1 WET BASINAlternative Names:

- Page 358 and 359: • Surcharge storage above the wet

- Page 360 and 361: Table 4.4-1: Wet Basin Inspection a

- Page 362 and 363: Figure 4.4-a: Wet Basin (Concept Dr

- Page 364 and 365: 4.4.1.2 BIOSWALEAlternative Names:

- Page 366 and 367: • Consider incorporating trees or

- Page 368 and 369: Figure 4.4-b: Bioswale (Linear Basi

- Page 370 and 371: 4.4.1.3 DRY BASINAlternative Names:

- Page 372 and 373: • Drainage design standards for t

- Page 374 and 375: INSPECTION AND MAINTENANCE ACTIVITI

- Page 376 and 377: Figure 4.4-c: Detention BasinTRPA B

- Page 378 and 379: 4.4.2 FLOW THROUGH TREATMENTFlow-th

- Page 380 and 381: 4.4.2.1 DROP INLET INSERTAlternativ

- Page 382 and 383: INSTALLATION CONSIDERATIONS• Refe

- Page 384 and 385:

4.4.2.2 TRASH RACKAlternate Names:

- Page 386 and 387:

4.4.2.3 BAFFLED VAULTAlternative Na

- Page 388 and 389:

• Ensure that site conditions all

- Page 390 and 391:

4.4.2.4 HYDRODYNAMIC SEPARATORAlter

- Page 392 and 393:

• Most units are designed to be c

- Page 394 and 395:

4.4.2.5 MEDIA FILTERAlternate Names

- Page 396 and 397:

Cartridge Filter• Cartridge filte

- Page 398 and 399:

• Vent the system as for undergro

- Page 400 and 401:

4.4.2.6 SEDIMENT TRAPAlternative Na

- Page 402 and 403:

INSPECTION AND MAINTENANCE• Regul

- Page 404 and 405:

Figure 4.4-e: Sediment TrapTRPA BMP

- Page 406 and 407:

CONTENTS4.5 Temporary BMPs for Cons

- Page 408 and 409:

4.5 TEMPORARY BMPS FOR CONSTRUCTION

- Page 410 and 411:

concrete washouts and stockpiles sh

- Page 412 and 413:

4.5.1.1 CONSTRUCTION PLANNING AND S

- Page 414 and 415:

• Measures to minimize the potent

- Page 416 and 417:

4.5.1.2 CONSTRUCTION BOUNDARY FENCI

- Page 418 and 419:

Figure 4.5-a: Construction Boundary

- Page 420 and 421:

4.5.1.3 DEWATERINGDESCRIPTIONDewate

- Page 422 and 423:

Figure 4.5-b: DewateringTRPA BMP Ha

- Page 424 and 425:

• Use this settled water to fill

- Page 426 and 427:

4.5.1.4 CLEAN WATER DIVERSIONAltern

- Page 428 and 429:

• Avoid disturbing aquatic specie

- Page 430 and 431:

• Pipe slope drain: A rigid pipe,

- Page 432 and 433:

Stream Isolation Techniques:• Tur

- Page 434 and 435:

Figure 4.5-f: Water DiversionTRPA B

- Page 436 and 437:

4.5.1.5 VEGETATION PROTECTIONAltern

- Page 438 and 439:

• Growing Space: Provide spacing

- Page 440 and 441:

Figure 4.5-g: Vegetation Protection

- Page 442 and 443:

4.5.1.6 TEMPORARY SANITATION FACILI

- Page 444 and 445:

4.5.1.7 DUST CONTROLAlternate Names

- Page 446 and 447:

• Blanket with geotextiles or veg

- Page 448 and 449:

4.5.1.8 VEHICLE INGRESS EGRESS MANA

- Page 450 and 451:

• If possible, re-use swept or va

- Page 452 and 453:

4.5.1.9 WINTERIZATIONDESCRIPTIONBet

- Page 454 and 455:

INSPECTION AND MAINTENANCEEnsure th

- Page 456 and 457:

4.5.1.10 CONSTRUCTION STAGINGAltern

- Page 458 and 459:

4.5.1.11 MATERIAL HANDLING STORAGE

- Page 460 and 461:

• Ensure that current Material Sa

- Page 462 and 463:

4.5.1.12 TOPSOIL SALVAGEAlternative

- Page 464 and 465:

• If topsoil will not be used for

- Page 466 and 467:

4.5.1.13 CONCRETE/BENTONITE MANAGEM

- Page 468 and 469:

Figure 4.5-i: Concrete Washout Stat

- Page 470 and 471:

4.5.1.14 STOCKPILE MANAGEMENTAltern

- Page 472 and 473:

Figure 4.5-j: Stockpile ManagementT

- Page 474 and 475:

4.5.2 EROSION AND SEDIMENT CONTROLR

- Page 476 and 477:

4.5.2.1 SWEEPINGDESCRIPTIONDuring c

- Page 478 and 479:

4.5.2.2 DRAIN INLET PROTECTIONAlter

- Page 480 and 481:

inches. Take care to ensure that no

- Page 482 and 483:

Figure 4.5-k: Drain Inlet Protectio

- Page 484 and 485:

4.5.2.3 FIBER ROLLAlternative Names

- Page 486 and 487:

• Adjust spacing of fiber rolls a

- Page 488 and 489:

Figure 4.5-l: Fiber RollsTRPA BMP H

- Page 490 and 491:

4.5.2.4 SILT FENCEAlternative Names

- Page 492 and 493:

• Turn the fabric uphill at the e

- Page 494 and 495:

Figure 4.5-m: Silt FenceTRPA BMP Ha

- Page 496 and 497:

4.5.2.5 EROSION CONTROL BLANKET SYS

- Page 498 and 499:

structures mark the boundaries of t

- Page 500 and 501:

Figure 4.5-p: Anchoring Geotextiles

- Page 502 and 503:

4.5.2.6 HYDROMULCH, TACKIFIER, AND

- Page 504 and 505:

INSPECTION AND MAINTENANCE• Hydro

- Page 506 and 507:

5.2 SOILSoil is a complex living sy

- Page 508 and 509:

Tilling green wood chips intothe so

- Page 510 and 511:

areas such as SEZs and in shorezone

- Page 512 and 513:

Large boulders provide permanent ve

- Page 514 and 515:

To address this TRPA’s Regional P

- Page 516 and 517:

to apply ½ inch of water. Water yo

- Page 518 and 519:

Pesticides can be degraded by sunli

- Page 520 and 521:

5.3.2.5 FIRE DEFENSIBLE SPACEFire d

- Page 522 and 523:

etween them. For example, shrubs wi

- Page 524 and 525:

5.4 PROJECT SCALE REQUIREMENTSSoil

- Page 526 and 527:

5.4.1.5 PROJECT INSTALLATIONA. CONT

- Page 528 and 529:

percent vegetative cover, soil surf

- Page 531 and 532:

TRPA Revegetation Plan TemplateSoil

- Page 533 and 534:

(c) GRADING AND SLOPE SHAPINGDescri

- Page 535 and 536:

TRPA Revegetation Plan ExampleSoil

- Page 537 and 538:

• All machinery must be clean bef

- Page 539 and 540:

Common NameScientific NameScotchbro

- Page 541 and 542:

during dry weather. All debris, roo

- Page 543 and 544:

substantially different that the pe

- Page 545:

TRPA BMP HandbookCHAPTER 5: Soil an

- Page 548 and 549:

Fertilizer Management PlanProject N

- Page 550 and 551:

IV. MONITORINGSurface and groundwat

- Page 552 and 553:

I. PROJECT AND SITE DESCRIPTIONGold

- Page 555:

Table 5-1: Description of Revegetat

- Page 558 and 559:

SITE TYPE RECOMMENDED SPECIES LISTS

- Page 560 and 561:

SITE TYPE RECOMMENDED SPECIES LISTW

- Page 562 and 563:

CHAPTER 5: Soil and Vegetation Mana

- Page 564 and 565:

TRPA APPROVED PLANT SPECIES ATTRIBU

- Page 566 and 567:

TRPA APPROVED PLANT SPECIES ATTRIBU

- Page 568 and 569:

CHAPTER 5: Soil and Vegetation Mana

- Page 570 and 571:

• Section 6.2 describes methods f

- Page 572 and 573:

equirements. At a minimum, training

- Page 574 and 575:

Vactor equipment removes sediment a

- Page 576 and 577:

Industrial Properties, Marinas, and

- Page 578 and 579:

• Rinse the rock with hose water

- Page 580 and 581:

EXAMPLE INSPECTION AND MAINTENANCE

- Page 582 and 583:

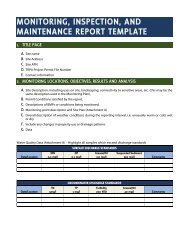

MONITORING PLAN TEMPLATE1. TITLE PA

- Page 584 and 585:

MONITORING, INSPECTION, ANDMAINTENA

- Page 586 and 587:

Sample Site123 Main StreetSouth Lak

- Page 588 and 589:

3. MONITORINGIn 2011, South Lake Ta

- Page 590 and 591:

ATTACHMENT BWATER QUALITY DATA

- Page 592 and 593:

ATTACHMENT DINSPECTION AND MAINTENC

- Page 594 and 595:

• Discharge of stormwater from in

- Page 596 and 597:

PAVING SINGLE FAMILY RESIDENTIAL PR

- Page 598 and 599:

TRPA Shorezone permit (www.trpa.org

- Page 600 and 601:

CHAPTER 8: SHOREZONE PROTECTIVESTRU

- Page 602 and 603:

technical guidance on structural an

- Page 604 and 605:

Pope has developed a shorezone miti

- Page 606 and 607:

ADVANTAGES• Protect parcel develo

- Page 608 and 609:

Table 8-3: Categorical Classificati

- Page 610 and 611:

generate observable changes in the

- Page 612 and 613:

Table 8-5: The General Geomorphic C

- Page 614 and 615:

8.1.8.2 TOLERANCE DISTRICT AND BACK

- Page 616 and 617:

Figure 8-e: Option 2—Backshore De

- Page 618 and 619:

Scenic Resources and project compli

- Page 620 and 621:

8.2 BULKHEADS AND LAKE WALLS8.2.1 O

- Page 622 and 623:

oth the beach immediately fronting

- Page 624 and 625:

Like all BMPs, bulkheads and lake w

- Page 626 and 627:

For a bulkhead located such that th

- Page 628 and 629:

Figure 8-i: Typical Lake Wall (Grav

- Page 630 and 631:

Table 8-9: Advantages and Disadvant

- Page 632 and 633:

maintains its position under wave s

- Page 634 and 635:

8.3.4 INSTALLATIONAs with bulkheads

- Page 636 and 637:

Table 8-11: Advantages and Disadvan

- Page 638 and 639:

V t ≥ 5R c2(Equation 4.1)Where:Vt

- Page 640 and 641:

8.5 BEACH NOURISHMENT AND REPLENISH

- Page 642 and 643:

of not being able to protect the ba

- Page 644 and 645:

• The material must be washed to

- Page 646 and 647:

nourishment will be determined by m

- Page 648 and 649:

Table 8-14: Advantages and Disadvan

- Page 650 and 651:

8.7 BREAKWATERS8.7.1 OVERVIEWBreakw

- Page 652 and 653:

The procedure for determining armor

- Page 654 and 655:

8.8 SHOREZONE VEGETATION8.8.1 OVERV

- Page 656 and 657:

vegetation. Protecting a tree from

- Page 658 and 659:

Overall, dredging can be either a p

- Page 660 and 661:

The Pneuma pump is a piece of dredg

- Page 662 and 663:

nature of the project and the poten

- Page 664 and 665:

8.10 TURBIDITY CURTAINS8.10.1 OVERV

- Page 666 and 667:

weights or connected firmly to sand

- Page 668 and 669:

Figure 8-o: Turbidity Curtain Desig

- Page 670 and 671:

Aquatic invasive species (AIS) also

- Page 672 and 673:

tanks into a sewage retention and/o

- Page 674 and 675:

• A common problem with recreatio

- Page 676 and 677:

8.12 BOAT RAMP CONSTRUCTION AND VEH

- Page 678 and 679:

Table 8-20: Advantages and Disadvan

- Page 680 and 681:

amp at the change of grade. A V-gro

- Page 682 and 683:

Figure 8-p: Boat Ramp DesignTRPA BM

- Page 684 and 685:

Table 8-22: Overview of Geotechnica

- Page 686 and 687:

8.14 SHOREZONE PROTECTIVE STRUCTURE

- Page 688 and 689:

8.14.2 ADDITIONAL CONSIDERATIONS FO

- Page 690 and 691:

some designated boundary or sphere

- Page 692 and 693:

spawning grounds and juvenile nurse

- Page 694 and 695:

Marine Science, School of Geoscienc

- Page 696 and 697:

Osborne, R.H., et. Al. (1985). Sedi

- Page 698 and 699:

8.16 APPENDICES8.16.1 DESIGN CALCUL

- Page 700 and 701:

Figure 8-r defines the primary wave

- Page 702 and 703:

8.16.1.2 WAVE RUN-UP FORMULA FOR BA

- Page 704 and 705:

• Use Equation 16.10 to calculate

- Page 706 and 707:

Figure 8-u: Design Wave CasesTRPA B

- Page 708 and 709:

Figure 8-v: Wave Setup and Run-Up f

- Page 710 and 711:

Alternative methods of wave calcula

- Page 712 and 713:

GLOSSARYAccretionMay be either a na

- Page 714 and 715:

eaches have no berm, others have se

- Page 716 and 717:

DensityMass (in kg) per unit of vol

- Page 718 and 719:

Fire Defensible SpaceRefers to the

- Page 720 and 721:

Common terms related to land covera

- Page 722 and 723:

PermeabilityThe property of a bulk

- Page 724 and 725:

ScourRemoval of underwater material

- Page 726 and 727:

SlopeThe degree of inclination to t

- Page 728 and 729:

Technical Advisory Committee (TAC)C

- Page 730 and 731:

ACRONYMSACES - Automated Coastal En

- Page 732 and 733:

NPS - Nonpoint SourceNRCS - Natural