- Page 1 and 2: �� complete proGram www.bti-Gro

- Page 3 and 4: Sealants and PU foams Workshop chem

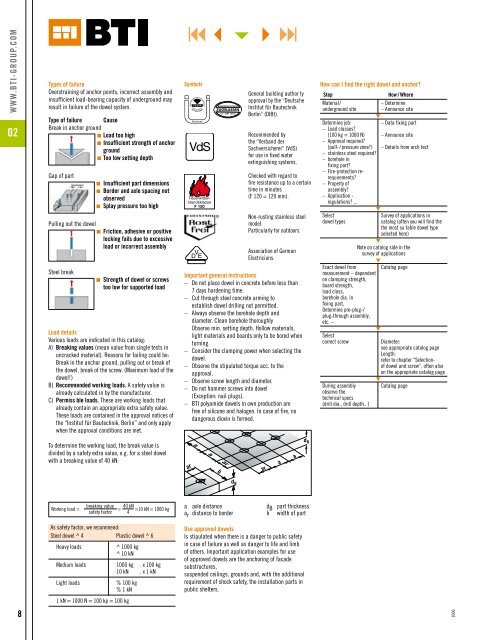

- Page 5 and 6: DOWEL TECHNOLOGY ����� Ny

- Page 7 and 8: 1006 Dowel technology ����

- Page 9 and 10: 1006 Standard fixings 1) For permit

- Page 11: 1006 How dowels work Dowels have th

- Page 15 and 16: 1006 ProCon X plus With flange With

- Page 17 and 18: 1006 ����� Express nail E

- Page 19 and 20: 1006 drill or hammer screw in Atten

- Page 21 and 22: 1006 Mounting pliers, straight Moun

- Page 23 and 24: 1006 LS LD Pull-out value in kN* LP

- Page 25 and 26: 1006 Assembly instruction: Make sur

- Page 27 and 28: 1006 HWP HWP in System-Eurobox 400

- Page 29 and 30: 1006 Z-21.2-2 1 Monitored Fire test

- Page 31 and 32: 1006 Nail plug B-SD…FK Flat flush

- Page 33 and 34: 1006 Flat-round cap for metal sleev

- Page 35 and 36: 1006 A firm anchoring of the insula

- Page 37 and 38: 1006 ����� Insulation uni

- Page 39 and 40: 1006 g With welded ring eye and woo

- Page 41 and 42: 1006 ����� Different fast

- Page 43 and 44: 1006 ����� Multi-Monti as

- Page 45 and 46: 1006 ����� Technical syst

- Page 47 and 48: 1006 Drill the borehole Hammer in t

- Page 49 and 50: 1006 Steel yellow ����� C

- Page 51 and 52: 1006 d a a a r Temperature Hardenin

- Page 53 and 54: 1006 KU- and metal sieve sleeves fo

- Page 55 and 56: 1006 ����� universal bond

- Page 57 and 58: 1006 ����� upat bonding t

- Page 59 and 60: ����� roof ventilation Ad

- Page 61 and 62: 1006 Mounting systems for roofs and

- Page 63 and 64:

1006 Safety features: • complies

- Page 65 and 66:

1006 Technical data Material stretc

- Page 67 and 68:

1006 'a' ����� Valley tro

- Page 69 and 70:

1006 Ridge end cover FES/ FES-Alu g

- Page 71 and 72:

1006 ����� AL-Vario the s

- Page 73 and 74:

1006 � Joint sealing tape � Vap

- Page 75 and 76:

1006 � Clamping felt � Vapor se

- Page 77 and 78:

1006 ����� Roof membranes

- Page 79 and 80:

1006 ����� Roof membrane

- Page 81 and 82:

1006 the professional window instal

- Page 83 and 84:

1006 the adhesive must be applied i

- Page 85 and 86:

1006 Window with internal rabbet Se

- Page 87 and 88:

1006 ����� Multi primer u

- Page 89 and 90:

1006 4W-toptec 45/11.5 plus Blade m

- Page 91 and 92:

1006 ����� Additional mat

- Page 93 and 94:

1006 The details specified in this

- Page 95 and 96:

1006 ����� Wood connector

- Page 97 and 98:

1006 BFA 300 x 2.0 �����

- Page 99 and 100:

1006 ����� bracket connec

- Page 101 and 102:

1006 Type D Drill template Type D 0

- Page 103 and 104:

Standard roof hook Flex roof hook 1

- Page 105 and 106:

1006 S O L A R M O u n t i n g �

- Page 107 and 108:

1006 S O L A R M O u n t i n g �

- Page 109 and 110:

1006 S O L A R M O u n t i n g �

- Page 111 and 112:

����� Drill and chiseling

- Page 113 and 114:

1006 Drilling, sawing, grinding, cu

- Page 115 and 116:

1006 Drilling, sawing, grinding, cu

- Page 117 and 118:

1006 SDS plus Item Unit dia. Workin

- Page 119 and 120:

1006 Improved design! SDS max �

- Page 121 and 122:

1006 SDS max chisel bit Bullpoint b

- Page 123 and 124:

1006 SDS plus only to be bored when

- Page 125 and 126:

1006 � � � � � � �

- Page 127 and 128:

1006 ����� DDS Extraction

- Page 129 and 130:

1006 Note: Your bTI sales engineer

- Page 131 and 132:

1006 ����� Drill stands 2

- Page 133 and 134:

1006 ����� Spot-drill ass

- Page 135 and 136:

1006 SW adapter SW point on m16 poi

- Page 137 and 138:

1006 Item Unit dia. Working Total n

- Page 139 and 140:

1006 Centering cylinder, especially

- Page 141 and 142:

1006 Tool steel sharpened Arbor-mou

- Page 143 and 144:

1006 only to be bored when turning,

- Page 145 and 146:

1006 L 1 L 2 Item Unit dia. L1 L2 n

- Page 147 and 148:

1006 L 1 L 2 Item Unit dia. L1 L2 n

- Page 149 and 150:

1006 one-sided, DIN 1897 double-sid

- Page 151 and 152:

1006 Usage instructions for bTI thr

- Page 153 and 154:

1006 ����� Threaded cutte

- Page 155 and 156:

1006 Type PG Item no.: 425044 Item

- Page 157 and 158:

1006 ����� Conical and de

- Page 159 and 160:

1006 ����� Plate holes as

- Page 161 and 162:

1006 Shaft and label color metal Wo

- Page 163 and 164:

1006 overview of jigsaw blades meta

- Page 165 and 166:

1006 Item No. Wood basicCut m 3.0/7

- Page 167 and 168:

1006 Item No. Wood SolidCut W 4.0/7

- Page 169 and 170:

1006 overview of reciprocating saw

- Page 171 and 172:

1006 Item No. metal LonglifeCut m 1

- Page 173 and 174:

1006 Item No. ����� Unit

- Page 175 and 176:

1006 In chapter Suitable saws 09 b

- Page 177 and 178:

1006 material Saw hard metal cylind

- Page 179 and 180:

1006 ����� Cylindrical sa

- Page 181 and 182:

1006 ••• very good cutting re

- Page 183 and 184:

1006 ����� master-Cut cir

- Page 185 and 186:

1006 ����� Uni-Cut circul

- Page 187 and 188:

1006 ����� Hard metal rev

- Page 189 and 190:

1006 For supporting disk straight r

- Page 191 and 192:

1006 ����� Sand paper rol

- Page 193 and 194:

1006 For use in the following machi

- Page 195 and 196:

1006 For use in the following machi

- Page 197 and 198:

1006 For use in the following machi

- Page 199 and 200:

1006 For use in the following machi

- Page 201 and 202:

1006 ����� Sanding belt F

- Page 203 and 204:

1006 ����� one-sided parq

- Page 205 and 206:

1006 ����� Parquet pad Fo

- Page 207 and 208:

1006 For use in the following machi

- Page 209 and 210:

1006 ����� Sanding mat, r

- Page 211 and 212:

1006 ����� Cutting off an

- Page 213 and 214:

1006 ����� Cutting wheel

- Page 215 and 216:

1006 ����� bSX TurboCut m

- Page 217 and 218:

1006 ����� basic brick Ra

- Page 219 and 220:

1006 overview of diamond cutting wh

- Page 221 and 222:

1006 ����� DTS Coolmax Hi

- Page 223 and 224:

1006 ����� DTS Coolmax Sp

- Page 225 and 226:

1006 ����� DTS Window Spe

- Page 227 and 228:

1006 ����� DTS Asphalt We

- Page 229 and 230:

1006 ����� Diamond cup wh

- Page 231 and 232:

����� For woodworking: Co

- Page 233 and 234:

1006 Screwing and fastening technol

- Page 235 and 236:

1006 A Cover cap for various applic

- Page 237 and 238:

1006 Page 287 Steel nail Countersun

- Page 239 and 240:

1006 g 12 mm cap-dia. g Ridge dia.

- Page 241 and 242:

1006 g 15 mm cap dia. g For screw w

- Page 243 and 244:

1006 ����� Water slot cap

- Page 245 and 246:

1006 ����� Winbag Simple

- Page 247 and 248:

1006 ����� toptec ® dist

- Page 249 and 250:

1006 Blade dimensions: Screw with i

- Page 251 and 252:

1006 Ideal for narrow notches and s

- Page 253 and 254:

1006 TX 25 Milling ribs ® Using th

- Page 255 and 256:

1006 blue galvanized blue galvanize

- Page 257 and 258:

1006 "Topcoat" coating 7,0 4,2 7,0

- Page 259 and 260:

1006 Examples of application: singl

- Page 261 and 262:

1006 Rolling shutter guideways Wind

- Page 263 and 264:

1006 Bit, TX Z-9.1-600 DoTec, Seko,

- Page 265 and 266:

1006 Countersunk head Raised counte

- Page 267 and 268:

1006 Bit, Pozidriv PZ 2 PZ 3 Counte

- Page 269 and 270:

1006 Bit, TX TX 25 TX 25 Countersun

- Page 271 and 272:

1006 Bit, Pozidriv PZ 1 PZ 2 PZ 2 P

- Page 273 and 274:

1006 quick and easy screwing along

- Page 275 and 276:

1006 Force 60% higher torque travel

- Page 277 and 278:

1006 ����� Terra-Vent-Sys

- Page 279 and 280:

1006 Multipurpose screw Electrical

- Page 281 and 282:

1006 Baufix dry wall screw SBS Made

- Page 283 and 284:

1006 Wood screw DIN 7995 Raised cou

- Page 285 and 286:

1006 in chapter Set screw 07 B Turn

- Page 287 and 288:

1006 ����� Bonding screw

- Page 289 and 290:

1006 Angular hook WH-LS with longit

- Page 291 and 292:

1006 smooth steel nail steel nail w

- Page 293 and 294:

1006 ����� Technical data

- Page 295 and 296:

1006 Center for staples and nails O

- Page 297 and 298:

1006 Cramp, type A, rustproof Test

- Page 299 and 300:

1006 HAUBOLD / KIHLBERG Cl. type Rb

- Page 301 and 302:

1006 HAUBOLD / KIHLBERG Cl. type kl

- Page 303 and 304:

����� For metalworking: D

- Page 305 and 306:

1006 Screwing and Fastening Technol

- Page 307 and 308:

1006 Page 331 Lock Washer former DI

- Page 309 and 310:

1006 ����� Plumber's scre

- Page 311 and 312:

1006 Stainless steel A2 polished Di

- Page 313 and 314:

1006 former DIN 7981 galvanized ste

- Page 315 and 316:

1006 ����� Diameter drill

- Page 317 and 318:

1006 ����� 4. Assortment/

- Page 319 and 320:

1006 ����� Drilling screw

- Page 321 and 322:

1006 Blade dimensions: screw with i

- Page 323 and 324:

1006 former DIN 965 galvanized stee

- Page 325 and 326:

1006 including the nut DIN 603 galv

- Page 327 and 328:

1006 DIN 912 galvanized steel, grad

- Page 329 and 330:

1006 former DIN 931 galvanized stee

- Page 331 and 332:

1006 Hexagonal head screw Former DI

- Page 333 and 334:

1006 former DIN 125 brass polished

- Page 335 and 336:

1006 Hinge hook ring Former DIN 127

- Page 337 and 338:

1006 Blind rivet Flat round head: g

- Page 339 and 340:

1006 Flat round head Rivet shaft: C

- Page 341 and 342:

1006 ����� Cupular blind

- Page 343 and 344:

1006 ����� Multi-range ri

- Page 345 and 346:

1006 ����� Hand riveting

- Page 347 and 348:

1006 � � � ����� Ri

- Page 349 and 350:

����� Fastening and conne

- Page 351 and 352:

1006 Electrical installation techno

- Page 353 and 354:

1006 Electrical installation techno

- Page 355 and 356:

1006 Blade dimensions Combination T

- Page 357 and 358:

1006 Steel, hardened, galvanized wi

- Page 359 and 360:

1006 � � ����� nylon

- Page 361 and 362:

1006 Multiple line diameters can be

- Page 363 and 364:

1006 Elastic clip head with large c

- Page 365 and 366:

1006 round clip bns-r gray clip mad

- Page 367 and 368:

1006 ����� nail washer Fo

- Page 369 and 370:

1006 ����� Parallel insta

- Page 371 and 372:

1006 hwP item unit number Pieces 00

- Page 373 and 374:

1006 ����� tunnel gland 9

- Page 375 and 376:

1006 Screw on angle adapter Work in

- Page 377 and 378:

1006 Wire-end ferrules on both side

- Page 379 and 380:

1006 � � � ����� ca

- Page 381 and 382:

1006 ����� screw-type cab

- Page 383 and 384:

1006 Recommended by the Fire Depart

- Page 385 and 386:

1006 CEE plug 16 A/32 A, 400 V, 5-p

- Page 387 and 388:

1006 ����� two-circuit sw

- Page 389 and 390:

1006 ����� grounding cont

- Page 391 and 392:

1006 ����� grounding cont

- Page 393 and 394:

1006 ����� Double rocker

- Page 395 and 396:

1006 ����� Decor color fr

- Page 397 and 398:

1006 ����� Electronic shu

- Page 399 and 400:

1006 ______ W ______ _ h _ Interior

- Page 401 and 402:

1006 Interior corner BGK Exterior c

- Page 403 and 404:

1006 ����� insulated tube

- Page 405 and 406:

1006 ����� cable pull fis

- Page 407 and 408:

1006 3 contact points 1.5 mm² 20 A

- Page 409 and 410:

1006 Rolls 10 m/5 m in length �

- Page 411 and 412:

1006 ����� copper ground

- Page 413 and 414:

1006 ����� wire end ferru

- Page 415 and 416:

1006 Female disconnects for cable c

- Page 417 and 418:

1006 item unit Designation number P

- Page 419 and 420:

1006 ����� cable pliers g

- Page 421 and 422:

1006 ����� cable shears V

- Page 423 and 424:

1006 ����� Electrical ins

- Page 425 and 426:

1006 Chisel-shaped 2.2 Chisel-shape

- Page 427 and 428:

����� Insulation Fastenin

- Page 429 and 430:

1006 Sanitation, heating, air condi

- Page 431 and 432:

1006 Sanitation, heating, air condi

- Page 433 and 434:

1006 Single-family house Heating Sa

- Page 435 and 436:

1006 ����� isovlies DN/is

- Page 437 and 438:

1006 At an elbow, adhesive tape is

- Page 439 and 440:

1006 Fire classificat on acc to DIN

- Page 441 and 442:

1006 ����� Item Unit Insu

- Page 443 and 444:

1006 ����� isoflex isofle

- Page 445 and 446:

1006 ����� Solar connecti

- Page 447 and 448:

1006 ����� isopren Solar

- Page 449 and 450:

1006 ����� Required thick

- Page 451 and 452:

1006 isopren 50 SV, 50 % EnEV �

- Page 453 and 454:

1006 ����� isowoll in rol

- Page 455 and 456:

1006 isopur 100 KU, plastic, 100 %

- Page 457 and 458:

1006 Miter meter Item Unit Designat

- Page 459 and 460:

1006 Pure aluminum tape A2 GGE B1 B

- Page 461 and 462:

1006 Vario-Sol PyroTape is laid in

- Page 463 and 464:

1006 ����� Fire-protectio

- Page 465 and 466:

1006 3 4 1 2 ����� Joint

- Page 467 and 468:

1006 ����� Double-screw c

- Page 469 and 470:

1006 ����� Double-screw c

- Page 471 and 472:

1006 � � ����� Perfor

- Page 473 and 474:

1006 Profi Standard Attention: Only

- Page 475 and 476:

1006 Toppro load tables If the rail

- Page 477 and 478:

1006 Load values for Toppro rail co

- Page 479 and 480:

1006 ����� For assembling

- Page 481 and 482:

1006 1) not suitable for stepped th

- Page 483 and 484:

1006 K.+J. Lueg OHG Institut für M

- Page 485 and 486:

1006 dia. 4 mm dia. 10/15 ���

- Page 487 and 488:

1006 13 26 80 117,5 100 150 24 13 3

- Page 489 and 490:

1006 Each set contains two of the s

- Page 491 and 492:

1006 Corresponds to DIN 1988 Final

- Page 493 and 494:

1006 ����� Bath installat

- Page 495 and 496:

1006 Empty nameplate, fluted: g The

- Page 497 and 498:

1006 Selection of profile rails A s

- Page 499 and 500:

1006 Pipe - dimensions, weights, fi

- Page 501 and 502:

1006 ����� Standard conne

- Page 503 and 504:

1006 ����� with noise-ins

- Page 505 and 506:

1006 ����� Stex quick ass

- Page 507 and 508:

1006 ����� Stex universal

- Page 509 and 510:

1006 ����� U-shackle SX 3

- Page 511 and 512:

1006 ����� C-profile, per

- Page 513 and 514:

1006 Fz Fz Fx Fx ����� St

- Page 515 and 516:

1006 F ����� Angle mount

- Page 517 and 518:

1006 ����� Joint support

- Page 519 and 520:

1006 Spacing bracket E25 Wall brack

- Page 521 and 522:

1006 Attention: Assembly clips for

- Page 523 and 524:

1006 Attention: Assembly clips for

- Page 525 and 526:

1006 A Fixed point Type clip type A

- Page 527 and 528:

1006 ����� Slider GL 37 F

- Page 529 and 530:

1006 ����� Ventilation pi

- Page 531 and 532:

1006 ����� Cold shrink ri

- Page 533 and 534:

1006 ����� Single-handed

- Page 535 and 536:

1006 ����� Hemp coil/hemp

- Page 537 and 538:

1006 ����� Electrical scr

- Page 539 and 540:

1006 g Adjustable in 7 positions (1

- Page 541 and 542:

1006 Extremely stable, robust lifti

- Page 543 and 544:

1006 020983 ����� Gas rad

- Page 545 and 546:

1006 ����� Propane high-p

- Page 547 and 548:

1006 Flat electrodes for universal

- Page 549 and 550:

����� Sealants and PU foa

- Page 551 and 552:

1006 Chemical technical products

- Page 553 and 554:

1006 Adhesives No. Powermont 140 1

- Page 555 and 556:

1006 * Definitions in accordance wi

- Page 557 and 558:

1006 BONDING + SEALING ����

- Page 559 and 560:

1006 BONDING + SEALING ����

- Page 561 and 562:

1006 BONDING + SEALING ����

- Page 563 and 564:

1006 BONDING + SEALING ����

- Page 565 and 566:

1006 BONDING + SEALING ����

- Page 567 and 568:

1006 BONDING + SEALING The details

- Page 569 and 570:

1006 BONDING + SEALING ����

- Page 571 and 572:

1006 CARE + CLEANING ����

- Page 573 and 574:

1006 BONDING + SEALING ����

- Page 575 and 576:

1006 BONDING + SEALING Ring nut C N

- Page 577 and 578:

1006 BONDING + SEALING siliconized

- Page 579 and 580:

1006 BONDING + SEALING Table to est

- Page 581 and 582:

1006 BONDING + SEALING Windows with

- Page 583 and 584:

1006 BONDING + SEALING Depiction of

- Page 585 and 586:

1006 BONDING + SEALING 1 2 1 = seal

- Page 587 and 588:

1006 BONDING + SEALING Verified by

- Page 589 and 590:

1006 � � BONDING + SEALING �

- Page 591 and 592:

1006 BONDING + SEALING ����

- Page 593 and 594:

1006 BONDING + SEALING ����

- Page 595 and 596:

1006 BONDING + SEALING ����

- Page 597 and 598:

1006 BONDING + SEALING ����

- Page 599 and 600:

1006 BONDING + SEALING ����

- Page 601 and 602:

1006 BONDING + SEALING ����

- Page 603 and 604:

1006 BONDING + SEALING ����

- Page 605 and 606:

1006 LUBRICATING + PROTECTING �

- Page 607 and 608:

1006 LUBRICATING + PROTECTING �

- Page 609 and 610:

1006 LUBRICATING + PROTECTING Dvgw*

- Page 611 and 612:

1006 LUBRICATING + PROTECTING Dvgw-

- Page 613 and 614:

1006 PRIMING + PAINTING � ��

- Page 615 and 616:

1006 CARE + CLEANING ����

- Page 617 and 618:

1006 CARE + CLEANING ����

- Page 619 and 620:

1006 CARE + CLEANING ����

- Page 621 and 622:

1006 FIRE PROTECTION ����

- Page 623 and 624:

1006 FIRE PROTECTION ����

- Page 625 and 626:

1006 FIRE PROTECTION ����

- Page 627 and 628:

TOOLS ����� Hand and scre

- Page 629 and 630:

1006 Tools ����� Table of

- Page 631 and 632:

1006 Longitudinal slot 1/4" Phillip

- Page 633 and 634:

1006 Phillips recessed head 1/4" No

- Page 635 and 636:

1006 Diamond coating (DC): For more

- Page 637 and 638:

1006 Pozidriv recessed head Torx (T

- Page 639 and 640:

1006 Yellow slider = Peak PZ Gray s

- Page 641 and 642:

1006 ����� item unit Desi

- Page 643 and 644:

1006 Laser e ����� Screwd

- Page 645 and 646:

1006 Tested Safety �����

- Page 647 and 648:

1006 Tested Safety �����

- Page 649 and 650:

1006 � � � � ����

- Page 651 and 652:

1006 5 mm 6 mm 7 - 8 mm 9 mm 3 - 5

- Page 653 and 654:

1006 A/f A/f 1/2" 3/8" ����

- Page 655 and 656:

1006 ����� Double open-en

- Page 657 and 658:

1006 ����� ring ratchet w

- Page 659 and 660:

1006 For prefiling (rough machining

- Page 661 and 662:

1006 ����� rali ® plane

- Page 663 and 664:

1006 Note: All saws are delivered i

- Page 665 and 666:

1006 Rapid 19 Rapid 11 Rapid 54 Rap

- Page 667 and 668:

1006 ����� Head compressi

- Page 669 and 670:

1006 ����� Coil nailer 7F

- Page 671 and 672:

1006 ����� Compressor Shu

- Page 673 and 674:

1006 ����� Lubricator For

- Page 675 and 676:

1006 Compressed air hose drum 20 m

- Page 677 and 678:

1006 Coupling with external thread

- Page 679 and 680:

1006 ����� ball peen hamm

- Page 681 and 682:

1006 ����� Flat chisel g

- Page 683 and 684:

1006 ����� universal plie

- Page 685 and 686:

1006 ����� Carpenter's pi

- Page 687 and 688:

1006 ����� workshop sciss

- Page 689 and 690:

1006 For figure cuts (also small ra

- Page 691 and 692:

1006 Trapezoid blade 1991 Snap-off

- Page 693 and 694:

1006 ����� Standard spatu

- Page 695 and 696:

1006 ����� Parat tool kit

- Page 697 and 698:

1006 ����� Fix grip quick

- Page 699 and 700:

1006 ����� All-steel scre

- Page 701 and 702:

1006 � � � ����� Cl

- Page 703 and 704:

1006 ����� round loop gS

- Page 705 and 706:

1006 Light metal water level Alumin

- Page 707 and 708:

1006 ����� Steel tape mea

- Page 709 and 710:

1006 � � ����� Plumb-

- Page 711 and 712:

1006 ����� Square for loc

- Page 713 and 714:

1006 ����� winkelfix goni

- Page 715 and 716:

1006 ����� infrared therm

- Page 717 and 718:

1006 ����� Laser Liner pl

- Page 719 and 720:

1006 ����� rotation laser

- Page 721 and 722:

1006 ����� wall holder Fo

- Page 723 and 724:

����� SYSTRA, SAFETY AT W

- Page 725 and 726:

1006 ����� Product lines,

- Page 727 and 728:

1006 ����� The SYSTRA Mod

- Page 729 and 730:

1006 ����� SYSTRA Modul 1

- Page 731 and 732:

1006 ����� SYSTRA Modul 1

- Page 733 and 734:

1006 ����� SYSTRA Modul 1

- Page 735 and 736:

1006 ����� SYSTRA Modul 1

- Page 737 and 738:

1006 ����� SYSTRA Modul 1

- Page 739 and 740:

1006 ����� SYSTRA Modul 1

- Page 741 and 742:

1006 ����� SYSTRA Modul 2

- Page 743 and 744:

1006 ����� SYSTRA Modul 1

- Page 745 and 746:

1006 ����� SYSTRA Modul m

- Page 747 and 748:

1006 ����� Die SYSTRA Mod

- Page 749 and 750:

1006 SYSTRA Modul 4 + toolbag set w

- Page 751 and 752:

1006 Front Back Front Back Front Ba

- Page 753 and 754:

1006 Front Back Front Back Front Ba

- Page 755 and 756:

1006 ����� ����

- Page 757 and 758:

1006 ����� ����

- Page 759 and 760:

1006 ����� ����

- Page 761 and 762:

1006 Front Back Front Back Front Ba

- Page 763 and 764:

1006 SYSTRA Modul mini accessories

- Page 765 and 766:

1006 ����� ����

- Page 767 and 768:

1006 Ball-bearing supported Full ex

- Page 769 and 770:

1006 ����� Insulated shel

- Page 771 and 772:

1006 1006 24 LP hooks short and lon

- Page 773 and 774:

1006 Assembly strip EL3B (with boxe

- Page 775 and 776:

1006 ����� Safe-Tex Prote

- Page 777 and 778:

1006 Skin-friendliness Dermatologic

- Page 779 and 780:

1006 ����� Fine dust mask

- Page 781 and 782:

1006 Work glove glove standard g In

- Page 783 and 784:

1006 Definition of terms Sternal ca

- Page 785 and 786:

1006 � � � � � � �

- Page 787 and 788:

1006 ����� Halogen portab

- Page 789 and 790:

1006 ����� Work light coo

- Page 791 and 792:

1006 Fig. SV 6-16/16 ����

- Page 793 and 794:

F3 WorkWear, ppe ����� F3

- Page 795 and 796:

1006 F3 Workwear, personal protecti

- Page 797 and 798:

1006 You will find additional color

- Page 799 and 800:

1006 We offer an individual labelin

- Page 801 and 802:

1006 ����� ����

- Page 803 and 804:

1006 ����� ����

- Page 805 and 806:

POWER TOOLS ����� Cordles

- Page 807 and 808:

1006 Power tools ����� Ta

- Page 809 and 810:

1006 ����� Cordless screw

- Page 811 and 812:

1006 ����� Cordless impac

- Page 813 and 814:

1006 ����� Cordless jig s

- Page 815 and 816:

1006 ����� Hammer drill B

- Page 817 and 818:

1006 ����� Hammer drill a

- Page 819 and 820:

1006 ����� Drill BTi-Bm 5

- Page 821 and 822:

1006 ����� Diamond core d

- Page 823 and 824:

1006 ����� One-hand angle

- Page 825 and 826:

1006 Overrun brake stops in 2.5 sec

- Page 827 and 828:

1006 ����� Jig saw BTi-ST

- Page 829 and 830:

1006 ����� Planer BTi-H 8

- Page 831 and 832:

1006 ����� Orbital sander

- Page 833 and 834:

1006 ����� Random orbital

- Page 835 and 836:

1006 Attention: Please be careful w

- Page 837 and 838:

1006 Suitable for BTi and makita co

- Page 839 and 840:

VEHICLE FLEET ����� Care

- Page 841 and 842:

1006 Vehicle fleet �����

- Page 843 and 844:

1006 DEKrA-approved �����

- Page 845 and 846:

1006 ����� orange Magic C

- Page 847 and 848:

1006 ����� Stainless stee

- Page 849 and 850:

100 ����� Cleaning cloth

- Page 851 and 852:

1006 ����� Silicone spray

- Page 853 and 854:

1006 ����� Hand lever gre

- Page 855 and 856:

1006 ����� Screw lock Ana

- Page 857 and 858:

1006 ����� pu constructio

- Page 859 and 860:

1006 ����� Zinc spray lig

- Page 861 and 862:

1006 ring ends for cable sections f

- Page 863 and 864:

1006 ����� SYSTrA Modul 1

- Page 865 and 866:

1006 ����� Nylon cable co

- Page 867 and 868:

1006 ����� Marker tag For

- Page 869 and 870:

1006 Rolls 10 m/5 m long ���

- Page 871 and 872:

1006 ����� bit selection

- Page 873 and 874:

1006 ����� Cross handle s

- Page 875 and 876:

1006 ����� Compressor Shu

- Page 877 and 878:

1006 ����� rubber hammer

- Page 879 and 880:

1006 g 7 adjustable settings (10" a

- Page 881 and 882:

1006 ����� one-hand wrenc

- Page 883 and 884:

1006 ����� Contractors bu

- Page 885 and 886:

1006 Index 1K and 2K polyurethane i

- Page 887 and 888:

1006 Cleaning products 772 Clear Vi

- Page 889 and 890:

1006 Diamond sharpening stick 226 D

- Page 891 and 892:

1006 Grip hack saw 659 Ground termi

- Page 893 and 894:

1006 Joint sealing tape VF 300 577

- Page 895 and 896:

1006 Parquet pad 201 Parquet sandin

- Page 897 and 898:

1006 S Saddle flange SX 35 / 35 503

- Page 899 and 900:

1006 Support 150 / 80 / 8 45 as con

- Page 901 and 902:

1006 Thread cutting die 148 Thread

- Page 903 and 904:

1006 ����� 899

- Page 905 and 906:

1006 1006 voices upon receipt and a

- Page 907:

1006 Information ��� In the c