- Page 1:

Salmonella enterica - biofilm forma

- Page 4 and 5:

Table of Contents Page Number 1.16.

- Page 6 and 7:

Table of Contents Page Number 4.1.2

- Page 8 and 9:

Table of Contents Page Number 6.8.4

- Page 10 and 11:

List of Abbreviations Table Page Nu

- Page 12 and 13:

List of Abbreviations List of Abbre

- Page 14 and 15: Summary of Content Summary of Conte

- Page 16 and 17: “To show your true ability is alw

- Page 18 and 19: Acknowledgements ever met, Fiona th

- Page 20 and 21: Acknowledgements This Ph.D. thesis

- Page 22 and 23: Chapter 1 1.1. Salmonella Salmonell

- Page 24 and 25: Chapter 1 may impose enormous costs

- Page 26 and 27: Chapter 1 cracks or penetration of

- Page 28 and 29: Chapter 1 detected by agglutination

- Page 30 and 31: Chapter 1 become colonized with >10

- Page 32 and 33: Chapter 1 antigens [z27],[z45] [1].

- Page 34 and 35: Chapter 1 S. Agona has also been im

- Page 36 and 37: Chapter 1 isolated from undercooked

- Page 38 and 39: Chapter 1 The S. Typhimurium strain

- Page 40 and 41: Chapter 1 ecosystem with the use of

- Page 42 and 43: Chapter 1 [82]. Previous research h

- Page 44 and 45: Chapter 1 to genes involved in flag

- Page 46 and 47: Chapter 1 observation has also been

- Page 48 and 49: Chapter 1 [119] and flow cell react

- Page 50 and 51: Chapter 1 based disinfectant) the s

- Page 52 and 53: Chapter 1 formation of two strains

- Page 54 and 55: Chapter 1 shield the S. Agona cells

- Page 56 and 57: Chapter 1 Key Objectives of this st

- Page 58 and 59: Chapter 2 2. Abstract Food-borne pa

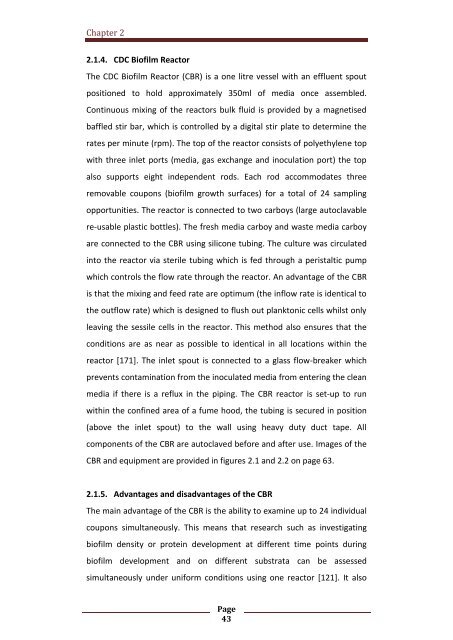

- Page 60 and 61: Chapter 2 indicated that there may

- Page 62 and 63: Chapter 2 taken from industrial set

- Page 66 and 67: Chapter 2 can be performed without

- Page 68 and 69: Chapter 2 To summarise, previous au

- Page 70 and 71: Chapter 2 2.3. Methods for examinin

- Page 72 and 73: Chapter 2 and the biofilm formed th

- Page 74 and 75: Chapter 2 2.4. Statistical Analysis

- Page 76 and 77: Chapter 2 Table 2.1: Strain charact

- Page 78 and 79: Chapter 2 XII. The gas port and med

- Page 80 and 81: Chapter 2 II. Primary fixative cons

- Page 82 and 83: Chapter 2 IX. Once the conditions w

- Page 84 and 85: Chapter 2 Figure 2.1: Image of CBR

- Page 86 and 87: Chapter 2 2.6. Results 2.6.1. Asses

- Page 88 and 89: Chapter 2 2.6.3. SEM Analysis of su

- Page 90 and 91: Chapter 2 Figure 2.6: Complete remo

- Page 92 and 93: Chapter 2 2.6.5. Mean log 10 densit

- Page 94 and 95: Chapter 2 2.6.6. Mean log 10 densit

- Page 96 and 97: Chapter 2 Table 2.5: Mean log 10 de

- Page 98 and 99: Chapter 2 The results displayed in

- Page 100 and 101: Chapter 2 Table 2.7: Difference bet

- Page 102 and 103: Chapter 2 Table 2.8: The mean log 1

- Page 104 and 105: Chapter 2 Figure 2.7: Graph of the

- Page 106 and 107: Chapter 2 also used “high” soni

- Page 108 and 109: Chapter 2 2.8. Summary All 13 strai

- Page 110 and 111: Chapter 3 3. Abstract It has been e

- Page 112 and 113: Chapter 3 classified as persistent

- Page 114 and 115:

Chapter 3 was plated onto TSA for e

- Page 116 and 117:

Chapter 3 Figure 3.1: The mean log

- Page 118 and 119:

Chapter 3 Figure 3.3: SEM image of

- Page 120 and 121:

Chapter 3 Table 3.2: Difference bet

- Page 122 and 123:

Chapter 3 3.4.3. Intra-serovar vari

- Page 124 and 125:

Chapter 3 3.4.4. Strain variation i

- Page 126 and 127:

Chapter 3 3.4.5. The density of bio

- Page 128 and 129:

Chapter 3 3.5. Discussion As illust

- Page 130 and 131:

Chapter 3 As discussed in section 3

- Page 132 and 133:

Chapter 3 increased biofilm appeare

- Page 134 and 135:

Chapter 4 Examining the efficacy of

- Page 136 and 137:

Chapter 4 through laboratory based

- Page 138 and 139:

Chapter 4 acid and quaternary ammon

- Page 140 and 141:

Chapter 4 the surface the temperatu

- Page 142 and 143:

Chapter 4 availability of multiple

- Page 144 and 145:

Chapter 4 peracetic acid (100, 200,

- Page 146 and 147:

Chapter 4 As discussed previously,

- Page 148 and 149:

Chapter 4 Dey/Engley (Difco) neutra

- Page 150 and 151:

Chapter 4 sterilisation was achieve

- Page 152 and 153:

Chapter 4 IX. Aliquots of 100µl of

- Page 154 and 155:

Chapter 4 XV. XVI. XVII. XVIII. XIX

- Page 156 and 157:

Chapter 4 4.3. Results 4.3.1. Suspe

- Page 158 and 159:

Chapter 4 Table 4.3: Mean log 10 de

- Page 160 and 161:

Chapter 4 Benzalkonium chloride was

- Page 162 and 163:

Chapter 4 4.4. Discussion Suspensio

- Page 164 and 165:

Chapter 4 effective at eliminating

- Page 166 and 167:

Chapter 4 Surprisingly, Nguyen et a

- Page 168 and 169:

Chapter 4 though a contact time of

- Page 170 and 171:

Chapter 4 provide a more standardis

- Page 172 and 173:

Chapter 4 hours instead of the stan

- Page 174 and 175:

Chapter 5 5. Abstract Examining bio

- Page 176 and 177:

Chapter 5 dry and rough (bdar) morp

- Page 178 and 179:

Chapter 5 absence of curli and cell

- Page 180 and 181:

Chapter 5 studies such as the micro

- Page 182 and 183:

Chapter 5 discussed in chapter 4. T

- Page 184 and 185:

Chapter 5 5.2. Methods 5.2.1. Colon

- Page 186 and 187:

Chapter 5 XIII. XIV. XV. XVI. XVII.

- Page 188 and 189:

Chapter 5 XVI. XVII. XVIII. XIX. XX

- Page 190 and 191:

Chapter 5 5.3.2. Repeatability of m

- Page 192 and 193:

Chapter 5 Figure 5.2: Stained biofi

- Page 194 and 195:

Chapter 5 was formed at room temper

- Page 196 and 197:

Chapter 5 Table 5.3: The density of

- Page 198 and 199:

Chapter 5 5.3.4. The density of bio

- Page 200 and 201:

Chapter 5 Table 5.6: The difference

- Page 202 and 203:

Chapter 5 Table 5.7: The difference

- Page 204 and 205:

Chapter 5 Table 5.8: Summary of ass

- Page 206 and 207:

Chapter 5 interpretation therefore

- Page 208 and 209:

Chapter 5 measures of S. enterica b

- Page 210 and 211:

Chapter 5 cells peaks [165, 191]. D

- Page 212 and 213:

Chapter 5 5.5. Limitations of the s

- Page 214 and 215:

Chapter 6 Discussion of S. enterica

- Page 216 and 217:

Chapter 6 However, a number of auth

- Page 218 and 219:

Chapter 6 It is of interest to exam

- Page 220 and 221:

Chapter 6 were similar at 48 hours.

- Page 222 and 223:

Chapter 6 attributable to a small n

- Page 224 and 225:

Chapter 6 chosen as an appropriate

- Page 226 and 227:

Chapter 6 undetermined. However, th

- Page 228 and 229:

Chapter 6 reason for this may be du

- Page 230 and 231:

Chapter 6 Moreover, based on the re

- Page 232 and 233:

Chapter 6 responsible for increased

- Page 234 and 235:

Chapter 6 not fully capture the ran

- Page 236 and 237:

Chapter 6 However, the extent of bi

- Page 238 and 239:

Chapter 6 6.10. Conclusions and rec

- Page 240 and 241:

Chapter 6 studies may solve some of

- Page 242 and 243:

Bibliography Bibliography Page 221

- Page 244 and 245:

Bibliography 12. T. Takata, J.L., H

- Page 246 and 247:

Bibliography 29. Barker, J., M. Nae

- Page 248 and 249:

Bibliography 47. Threlfall, E.J., H

- Page 250 and 251:

Bibliography 65. CDC. Investigation

- Page 252 and 253:

Bibliography 83. Ledeboer, N., Frye

- Page 254 and 255:

Bibliography 100. Chia, T., Goulter

- Page 256 and 257:

Bibliography 117. Buckingham-Meyer,

- Page 258 and 259:

Bibliography 133. European Committe

- Page 260 and 261:

Bibliography Supernatant of a Hafni

- Page 262 and 263:

Bibliography 165. Díez-García, M.

- Page 264 and 265:

Bibliography cultivation of Staphyl

- Page 266 and 267:

Bibliography Compounds. 2012. Appli

- Page 268 and 269:

Bibliography 215. Buck, et al., A q

- Page 270 and 271:

Bibliography Canadian Journal of Ps

- Page 272 and 273:

Appendix 1 Appendix 1— List of Re

- Page 274 and 275:

Appendix 1 Appendix 1 - List of Equ

- Page 276 and 277:

Appendix 2 Colour index High outlie

- Page 278 and 279:

Appendix 2 Colour index High outlie

- Page 280 and 281:

Appendix 2 Colour index High outlie

- Page 282 and 283:

Appendix 2 Colour index High outlie

- Page 284 and 285:

Appendix 2 Colour index High outlie

- Page 286 and 287:

Appendix 3 Appendix 3-Figure 2: PFG

- Page 288 and 289:

Appendix 4 Poster Presentation Envi