- Page 1 and 2:

A PHYSICAL IMPLEMENTATION WITH CUST

- Page 3 and 4:

A PHYSICAL IMPLEMENTATION WITH CUST

- Page 5 and 6:

4.0 ASIC DESIGN FLOW ..............

- Page 7 and 8:

6.5.5 Characterization Results for

- Page 9 and 10:

LIST OF TABLES Table 5-1: ALU Modul

- Page 11 and 12:

LIST OF FIGURES Figure 1-1: SuperCI

- Page 13 and 14:

Figure 5-20: BIGFABRIC Logical Diag

- Page 15 and 16:

Figure 7-4: EEPROM Erase Physical O

- Page 17 and 18:

ACKNOWLEDGEMENTS “Many, O Jehovah

- Page 19 and 20:

1.0 INTRODUCTION Technological adva

- Page 21 and 22:

Property) block. The physical desig

- Page 23 and 24:

the thesis proposes a power gated m

- Page 25 and 26:

2.0 SUPERCISC RECONFIGURABLE HARDWA

- Page 27 and 28:

The specifications of the hardware

- Page 29 and 30:

INP2 selects from ALU1, ALU2, ALU3

- Page 31 and 32:

3.0 POWER ESTIMATION The need for e

- Page 33 and 34:

3.1.1 Static Power Consumption Stat

- Page 35 and 36:

Internal Power Internal Power is th

- Page 37 and 38:

Switching activity Generation Switc

- Page 39 and 40:

Figure 3-4: Leakage Power definitio

- Page 41 and 42:

The entire array contains informati

- Page 43 and 44:

3.3.2 Calculation of Fall Power Fig

- Page 45 and 46:

Figure 3-10: Off-state leakage Powe

- Page 47 and 48:

Figure 4-1 : Typical ASIC Design Fl

- Page 49 and 50:

Figure 4-2: ASIC Physical Design Fl

- Page 51 and 52:

4.1.2 Powerplanning Power planning

- Page 53 and 54:

created in the design. Routing feed

- Page 55 and 56:

4.1.7 Routing Once the standard cel

- Page 57 and 58:

Table 5-1: ALU Module Specification

- Page 59 and 60:

Table 5-2 shows the important speci

- Page 61 and 62:

the basic parameters are specified,

- Page 63 and 64:

direction have to be aligned on the

- Page 65 and 66:

ALU Stripe Pin Assignment The “ib

- Page 67 and 68:

5.2.1 MUX Module Specifications As

- Page 69 and 70:

Figure 5-12: MUX Stripe Logical Dia

- Page 71 and 72:

MUX initialization routine The MUX

- Page 73 and 74: Table 5-10: MUX Stripe Pin Placemen

- Page 75 and 76: Figure 5-15: FINALMUX Module Logica

- Page 77 and 78: Table 5-12: Final MUX Stripe Specif

- Page 79 and 80: pins in the FINALMUX stripe is plac

- Page 81 and 82: larger system. Figure 5-22 shows th

- Page 83 and 84: Figure 5-20: BIGFABRIC Logical Diag

- Page 85 and 86: Figure 5-22: Place and Routed BIGFA

- Page 87 and 88: BIGFABRIC Stripe Pin Assignment As

- Page 89 and 90: The SPEF file can be generated usin

- Page 91 and 92: 5.5.1 Power Results for ADPCM Encod

- Page 93 and 94: 5.5.3 Power Results for IDCT Row Be

- Page 95 and 96: 5.5.5 Power Results for Sobel Bench

- Page 97 and 98: 6.0 DELAY ELEMENTS FOR LOW POWER FA

- Page 99 and 100: Transmission gate with Schmitt Trig

- Page 101 and 102: PMOS transistors have their gate in

- Page 103 and 104: output normally. The signal integri

- Page 105 and 106: m-Transistor Cascaded Inverter This

- Page 107 and 108: 6.2 LOW POWER FABRIC USING DELAY EL

- Page 109 and 110: The use of delay elements in the ha

- Page 111 and 112: 6.3.2 Dynamic Triggering Scheme A d

- Page 113 and 114: Figure 6-16 shows the shunt current

- Page 115 and 116: td1 is the delay in discharging nod

- Page 117 and 118: δt is the regeneration time of the

- Page 119 and 120: transistors, they are active low si

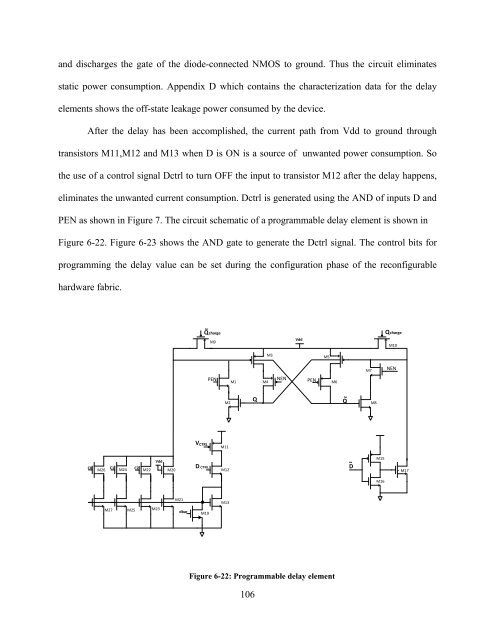

- Page 121 and 122: delay elements are enabled on a log

- Page 123: charge sharing happens between the

- Page 127 and 128: uffer with a drive capacity of 640f

- Page 129 and 130: Cell Rise Delay The Cell Rise Delay

- Page 131 and 132: Fall Transition Time The time taken

- Page 133 and 134: 6.5.6 Characterization Results for

- Page 135 and 136: 7.0 EEPROM CIRCUIT DESIGN EEPROM (E

- Page 137 and 138: 7.1.1 Erase Operation Figure 7-3: I

- Page 139 and 140: 7.1.2 Write Operation Figure 7-6: I

- Page 141 and 142: Figure 7-9: IV Characteristics of a

- Page 143 and 144: The current source IFN, resistor RT

- Page 145 and 146: Figure 7-11: HSPICE Description of

- Page 147 and 148: 7.2.1 Ramp Generator The ramp gener

- Page 149 and 150: 7.2.4 Column Latch for Bitlines inp

- Page 151 and 152: 7.2.5 Power Multiplexer Figure 7-16

- Page 153 and 154: The inverter pair connected to the

- Page 155 and 156: 7.2.7 Memory Bank Architecture Figu

- Page 157 and 158: 7.2.8 Memory Bank Simulation Figure

- Page 159 and 160: (Vpp) and a normal voltage (Vdd), t

- Page 161 and 162: 8.1.2 Dynamic Decoder The address d

- Page 163 and 164: 8.3 POWER-ON RESET One problem with

- Page 165 and 166: Figure 8-6 shows the modified charg

- Page 167 and 168: To study the impact of the power co

- Page 169 and 170: 9.0 CONCLUSION For this thesis, I h

- Page 171 and 172: definitions, metal layer resistance

- Page 173 and 174: APPENDIX B element standard cell ch

- Page 175 and 176:

$k=-1; $j=-1; $i=-1; foreach $ load

- Page 177 and 178:

$FALL_START_8 = $OFFSET8 + $ONTIME;

- Page 179 and 180:

if ($#rise_power_6 == -1) { # $modi

- Page 181 and 182:

$modified_spice_array[$i] = $temp2;

- Page 183 and 184:

@fall_power_9 = grep(/fall_power9/,

- Page 185 and 186:

print MEASHANDLE $_; print ENERGYHA

- Page 187 and 188:

} print MEASHANDLE " "; print ENERG

- Page 189 and 190:

set VAL [expr "$NUMBER_OF_MODULES_P

- Page 191 and 192:

set DIE_WIDTH_STRIPE [expr {($MODUL

- Page 193 and 194:

#*************************PLACING i

- Page 195 and 196:

preassignPin stripe $PIN_NAME -loc

- Page 197 and 198:

set X_LOC [expr {($X _LOC -( 31*$OU

- Page 199 and 200:

#Module related details set NUMBER_

- Page 201 and 202:

set X_LOC 0 set Y_LOC 41.2 for {set

- Page 203 and 204:

Table D 1 (Continued) 506.232fF 0.0

- Page 205 and 206:

121.344fF 0.076ns 0.4634 0.2277 570

- Page 207 and 208:

Table D 5 (Continued) 9.48 0. 516 0

- Page 209 and 210:

Table D 7: Characterization data fo

- Page 211 and 212:

Transi tion Table D 9: Characteriza

- Page 213 and 214:

[13] M.F. Aburdene, J. Zheng, and R