- Page 1 and 2:

INCH-POUNDDOE STANDARDDOE-STD-1 090

- Page 3:

DISCLAIMERPortions of this document

- Page 7 and 8:

DOE-STD-I090-96 (Rev-I)7.5.6 Attach

- Page 9 and 10:

DOE-STD-I090-96 (Rev-I)9.2.6.3 Hydr

- Page 11 and 12:

DOE-STD-1090-96 (Rev-l)11.2.3.1 6 x

- Page 13 and 14:

DOE-STD-1090-96 (Rev-l)13.4.5 Disco

- Page 15 and 16:

DOE-STD-I090-96 (Rev-I)15.4.2 Mobil

- Page 18 and 19:

DOE-STD-I090-96 (Rev-I)History and

- Page 20 and 21:

DOE-STD-I090-96 (Rev-I)Acknowledgme

- Page 22 and 23:

DOE-STD-I090-96 (Rev-I)Introduction

- Page 24 and 25:

DOE-STD-I090-96 (Rev-I)CHAPTER 1TER

- Page 26 and 27:

DOE-STD-I090-96 (Rev-I)CLOSING LINE

- Page 28 and 29:

DOE-STD-I090-96 (Rev-I)END CONTROL:

- Page 30 and 31:

LIFT, PREENGINEERED PRODUCTION:Repe

- Page 32 and 33:

QUALIFIED ENGINEER/QUALIFIEDENGINEE

- Page 35 and 36:

DOE-STD-I090-96 (Rev-I)INTENTIONALL

- Page 37 and 38:

-----------------------------------

- Page 39 and 40:

DOE-STD-I090-96 (Rev-I)2.2 CRITICAL

- Page 41 and 42:

DOE-STD-1090-96 (Rev-1)INTENTIONALL

- Page 43 and 44:

DOE-STD-I090-96 (Rev-I)3.2 OPERATIO

- Page 45 and 46:

DOE-STD-I090-96 (Rev-I)2. Perform a

- Page 47 and 48:

DOE-STD-I090-96 (Rev-I)3.4.4 Approv

- Page 49 and 50:

DOE-STD-I090-96 (Rev-I)3.6 TRAINING

- Page 51 and 52:

DOE-STD-I090-96 (Rev-I)INTENTIONALL

- Page 53 and 54:

DOE-STD-I090-96 (Rev-I)that create

- Page 55 and 56:

4.3 OVERHEAD CRANESDOE-STD-I090-96

- Page 57 and 58:

DOE-STD-I090-96 (Rev-I)lNTENTIONAIL

- Page 59 and 60:

DOE-STD-I090-96 (Rev-I)INTENTIONALL

- Page 61 and 62:

DOE-STD-I090-96 (Rev-I)5.2 HOSTILE

- Page 63 and 64:

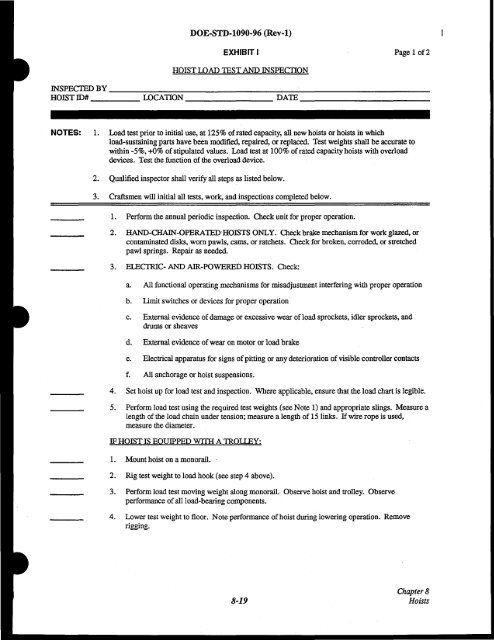

DOE-STD-1090-96 (Rev-l)EXHIBIT IHOS

- Page 65 and 66:

DOE-STD-I090-96 (Rev-I)INTENTIONALL

- Page 67 and 68:

6.2 QUALIFICATIONDOE-STD-I090-96 (R

- Page 69 and 70:

6.2.5Operators of ForkliftTrucksa.

- Page 71 and 72: DOE-STD-I090-96 (Rev-I)6.3 TRAINING

- Page 73 and 74: DOE-STD-1090-96 (Rev-l)24. Records

- Page 75 and 76: 6.4 REQUALIFICATIONDOE-STD-I090-96

- Page 77 and 78: -----------------------------------

- Page 79 and 80: -----------------------------------

- Page 81 and 82: DOE-STD-I090-96 (Rev-!)Gantry Crane

- Page 83 and 84: DOE-STD-I090-96 (Rev-I)Crane bridge

- Page 85 and 86: DOE-STD-I090-96 (Rev-I)7.2 INSPECTI

- Page 87 and 88: DOE-STD-I090-96 (Rev-I)h. Chain-dri

- Page 89 and 90: DOE-STD-I090-96 (Rev-I)trouble pers

- Page 91 and 92: DOE-STD-I090-96 (Rev-I)7.4 MAINTENA

- Page 93 and 94: DOE-STD-I090-96 (Rev-I)HOIST. With

- Page 95 and 96: DOE-STD-I090-96 (Rev-I)g. Do not lo

- Page 97 and 98: DOE-STD-1090-96 (Rev-l). IN1ENTIONA

- Page 99 and 100: DOE-STD-1090-96 (Rev-l)EXHIBIT I (c

- Page 101 and 102: DOE-STD-I090-96 (Rev-I)EXHIBIT I (c

- Page 103 and 104: DOE-STD-I090-96 (Rev-I)8.3 TESTING

- Page 105 and 106: DOE-STD-I090-96 (Rev-I)Figure 8-3.

- Page 107 and 108: DOE-STD-I090-96 (Rev-I)8.1.1Operato

- Page 109 and 110: DOE-STD-I090-96 (Rev-I)operating co

- Page 111 and 112: DOE-STD-I090-96 (Rev-I)8.2 INSPECTI

- Page 113 and 114: DOE-STD-I090-96 (Rev-I)2. A number

- Page 115 and 116: DOE-STD-!090-96 (Rev-!)iv.Inspect f

- Page 117 and 118: DOE-STD-I090-96 (Rev-I)8.4 MAINTENA

- Page 119 and 120: DOE-STD-I090-96 (Rev-I)d. Do not op

- Page 121: DOE-STD-I090-96 (Rev-I)Exhibit I is

- Page 125 and 126: DOE-STD-I090-96 (Rev-I)9.5.29.5.39.

- Page 127 and 128: DOE-STD-I090-96 (Rev-I)Table 9-1. S

- Page 129 and 130: DOE-STD-1090-96 (Rev-1)r-1r.ilE3...

- Page 131 and 132: DOE-STD-I090-96 (Rev-I)9.2 INSPECTI

- Page 133 and 134: DOE-STD-I090-96 (Rev-I)d. Evidence

- Page 135 and 136: DOE-STD-I090-96 (Rev-I)before retur

- Page 137 and 138: DOE-STD-I090-96 (Rev-I)9.4 MAINTENA

- Page 139 and 140: DOE-STD-I090-96 (Rev-!)t. Lock carr

- Page 141 and 142: DOE-STD-I090-96 (Rev-I)Figure 9-2.

- Page 143 and 144: DOE-STD-1090-96 (Rev-1)c. Durable s

- Page 145 and 146: DOE-STD-I090-96 (Rev-I)1. Cranel10a

- Page 147 and 148: DOE-STD-I090-96 (Rev-I)IIIIIIIIIIII

- Page 149 and 150: DOE·STD·I090·96 (Rev-I)HOIST. Wi

- Page 151 and 152: DOE-STD-I090-96 (Rev-I)RETRACT 800M

- Page 153 and 154: DOE-STD-I090-96 (Rev-I)Exhibit I is

- Page 155 and 156: DOE-STD-I090-96 (Rev-I)EXHIBIT I (c

- Page 157 and 158: DOE-STD-I090-96 (Rev-I)EXHIBIT I (c

- Page 159 and 160: DOE-STD-1090-96 (Rev-1)10.5.5 Movin

- Page 161 and 162: DOE-STD-I090-96 (Rev-I)10.1.6 Modif

- Page 163 and 164: DOE-STD-I090-96 (Rev-I)1. Class I-l

- Page 165 and 166: DOE-STD-I090-96 (Rev-I)CAUTIONONLY

- Page 167 and 168: -- ----------------------------10.4

- Page 169 and 170: DOE-STD-1090-96 (Rev-l)20. To avoid

- Page 171 and 172: DOE-STD-1090-96 (Rev-1)RAISE THE TI

- Page 173 and 174:

-- -----------DOE-STD-I090-96 (Rev-

- Page 175 and 176:

DOE-STD-I090-96 (Rev-I)EXHIBIT I (c

- Page 177 and 178:

DOE-STD-I090-96 (Rev-I)INTENTIONALL

- Page 179 and 180:

DOE-STD-1090-96 (Rev-l)Table 11-1.

- Page 181 and 182:

DOE-STD-I090-96 (Rev-I)11.2 WIRE RO

- Page 183 and 184:

-~ --~---------------------------DO

- Page 185 and 186:

DOE-STD-I090-96 (Rev-I)11.3 SLINGS1

- Page 187 and 188:

DOE-STD-1090-96 (Rev-1)11.3.1.3 Des

- Page 189 and 190:

DOE-STD-I090-96 (Rev-I)Table 11-4.

- Page 191 and 192:

DOE-STD-I090-96 (Rev-I)Table 11-6.

- Page 193 and 194:

DOE-STD-1090-96 (Rev-l)Table 11-8.

- Page 195 and 196:

DOE-STD-I090-96 (Rev-I)Angle of cho

- Page 197 and 198:

DOE-STD-I090-96 (Rev-I)temperatures

- Page 199 and 200:

DOE-STD-I090-96 (Rev-!)7. Locate sl

- Page 201 and 202:

-------------------DOE-STD-I090-96

- Page 203 and 204:

-_.._-----~------------DOE-STD-I090

- Page 205 and 206:

DOE-STD-I090-96 (Rev-I)Table 11-13.

- Page 207 and 208:

DOE·STD·I090·96 (Rev-I)q. Never

- Page 209 and 210:

DOE-STD-I090-96 (Rev-I)j. Despite t

- Page 211 and 212:

DOE-STD-I090-96 (Rev-I)Table 11-14.

- Page 213 and 214:

DOE·STD·1090-96 (Rev-1)certificat

- Page 215 and 216:

DOE-STD-I090-96 (Rev-I)Exhibits I t

- Page 217 and 218:

DOE-STD-1090-96 (Rev-l)lNTENTIONALL

- Page 219 and 220:

------DOE-STD-I090-96 (Rev-I)EXHIBI

- Page 221 and 222:

DOE-STD-I090-96 (Rev-I)INTENTIONALL

- Page 223 and 224:

DOE-STD-1090-96 (Rev-l)INTENTIONALL

- Page 225 and 226:

-----------------------------------

- Page 227 and 228:

DOE-STD-I090-96 (Rev-I)Good and Bad

- Page 229 and 230:

12.2 RIGGING HOOKSDOE-STD-I090-96 (

- Page 231 and 232:

DOE-STD-I090-96 (Rev-I)2. Heavy ser

- Page 233 and 234:

DOE-STD-I090-96 (Rev-I)Typical shac

- Page 235 and 236:

DOE-STD-I090-96 (Rev-I)• Shoulder

- Page 237 and 238:

12.5 TURNBUCKLESDOE-STD-I090-96 (Re

- Page 239 and 240:

12.6 LINKS AND RINGSDOE-STD-I090-96

- Page 241 and 242:

DOE-STD-I090-96 (Rev-I)12.7 METAL-P

- Page 243 and 244:

DOE-STD-I090-96 (Rev-I)Exhibit I is

- Page 245 and 246:

---------------------------DOE-STD-

- Page 247 and 248:

DOE-STD-I090-96 (Rev-I)INTENTIONALL

- Page 249 and 250:

DOE-STD-1090-96 (Rev-l)13.2 INSPECT

- Page 251 and 252:

DOE-STD-I090-96 (Rev-I)13.3 TESTING

- Page 253 and 254:

DOE-STD-1090-96 (Rev-l)13.4 NONDEST

- Page 255 and 256:

-------------------------------~--1

- Page 257 and 258:

-----------------------------------

- Page 259 and 260:

DOE-STD-1090-96 (Rev-1)14.4.4.3 Per

- Page 261 and 262:

DOE-STD-I090-96 (Rev-I)14.2 STRUCTU

- Page 263 and 264:

.----------------------------------

- Page 265 and 266:

DOE-STD-I090-96 (Rev-I)14.2.7 Maint

- Page 267 and 268:

DOE-STD-I090-96 (Rev-!)Four-pad pow

- Page 269 and 270:

DOE-STD-I090-96 (Rev-I)14.3.5 Testi

- Page 271 and 272:

DOE-STD-I090-96 (Rev-I)14.4 MAGNETS

- Page 273 and 274:

DOE-STD-I090-96 (Rev-I)1. External

- Page 275 and 276:

DOE-STD-I090-96 (Rev-I)instructed b

- Page 277 and 278:

- ---------------------------------

- Page 279 and 280:

DOE-STD-I090-96 (Rev-I)6. Charging

- Page 281 and 282:

DOE-STD-!090-96 (Rev-!)EXHIBIT IPag

- Page 283 and 284:

-------------------~---------------

- Page 285 and 286:

DOE·STD·I090-96 (Rev-I)15.2 DEFIN

- Page 287 and 288:

General note for Figures 15-5 throu

- Page 289 and 290:

DOE-STD-I090-96 (Rev-I)LIFT, ORDINA

- Page 291 and 292:

DOE-STD-1090~96 (Rev-l)Consideratio

- Page 293 and 294:

DOE-STD-I090-96 (Rev-I)15.4.2.4 Fre

- Page 295 and 296:

DOE-STD-I090-96 (Rev-I)4. Corroded

- Page 297 and 298:

DOE-STD-I090-96 (Rev-I)attention to

- Page 299 and 300:

DOE-STD-I090-96 (Rev-I)b. Test load

- Page 301 and 302:

DOE-STD-!090-96 (Rev-!)regardless Q

- Page 303 and 304:

DOE-STD-1090-96 (Rev-1)EMERGENCY ST

- Page 305 and 306:

DOE-STD-I090-96 (Rev-I)so by an app

- Page 307 and 308:

DOE-STD-I090-96 (Rev-I)Figure 15-13

- Page 309 and 310:

DOE-STD-I090-96 (Rev-I)Figure 15-14

- Page 311 and 312:

DOE-STD-I090-96 (Rev-I)Figure 15-15

- Page 313 and 314:

DOE-STD-I090-96 (Rev-I)include the

- Page 315 and 316:

DOE-STD-1090-96 (Rev-l)the platform

- Page 317 and 318:

DOE-STD-I090-96 (Rev-I)h. Report an

- Page 319 and 320:

DOE-STD-!090-96 (Rev-!)fRAISE THE T

- Page 321 and 322:

DOE-STD-I090-96 (Rev-I)h. Provide 4

- Page 323 and 324:

DOE-STD-1090-96 (Rev-l)ASME B56.7,

- Page 325 and 326:

DOE-STD-I090-96 (Rev-I)INTENTIONALL