DOE-STD-1090-96, DOE Standard Hoisting and Rigging Manual ...

DOE-STD-1090-96, DOE Standard Hoisting and Rigging Manual ...

DOE-STD-1090-96, DOE Standard Hoisting and Rigging Manual ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

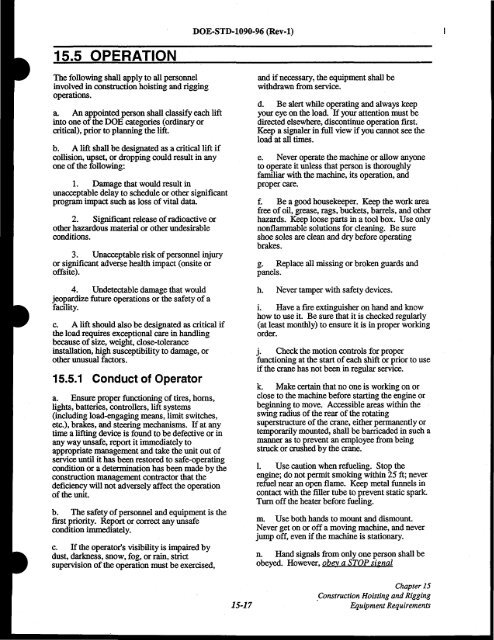

<strong>DOE</strong>-<strong>STD</strong>-I090-<strong>96</strong> (Rev-I)15.5 OPERATIONThe following shall apply to all personnelinvolved in construction hoisting <strong>and</strong> riggingoperations.a. An appointed person shall classify each liftinto oneofthe <strong>DOE</strong> categories (ordinary orcritical), prior to planning the lift.b. A lift shall be designated as a critical lift ifcollision, upset, or dropping could result in anyone ofthe following:1. Damage that would result inunacceptable delay to schedule or other significantprogram impact such as loss ofvital data.2. Significant release ofradioactive orother hazardous material or other undesirableconditions.3. Unacceptable risk ofpersonnel injuryor significant adverse health impact (onsite oroffsite).4. Undetectable damage that wouldjeopardize future operations or the safety of afacility.c. A lift should also be designated as critical ifthe load requires exceptional care in h<strong>and</strong>lingbecause ofsize, weight, close-toleranceinstallation, high susceptibility to damage, orother unusual factors.15.5.1 Conduct of Operatora. Ensure proper functioning oftires, horns,lights, batteries, controllers, lift systems(including load-engaging means, limit switches,etc.), brakes, <strong>and</strong> steering mechanisms. Ifat anytime a lifting device is found to be defective or inany way unsafe, report it immediately toappropriate management <strong>and</strong> take the unit out ofservice until it has been restored to safe-operatingcondition or a determination has been made by theconstruction management contractor that thedeficiency will not adversely affect the operationofthe unit.b. The safety ofpersonnel <strong>and</strong> equipment is thefirst priority. Report or correct any unsafecondition immediately.c. Ifthe operator's visibility is impaired bydust, darlmess, snow, fog, or rain, strictsupervision ofthe operation must be exercised,<strong>and</strong> ifnecessary, the equipment shall bewithdrawn from service.d. Be alert while operating <strong>and</strong> always keepyour eye on the load. Ifyour attention must bedirected elsewhere, discontinue operation first.Keep a signaler in full view ifyou cannot see theload at all times.e. Never operate the machine or allow anyoneto operate it unless that person is thoroughlyfamiliar with the machine, its operation, <strong>and</strong>proper care.f. Be a good housekeeper. Keep the work areafree ofoil, grease, rags, buckets, barrels, <strong>and</strong> otherhazards. Keep loose parts in a tool box. Use onlynonflammable solutions for cleaning. Be sureshoe soles are clean <strong>and</strong> dry before operatingbrakes.g. Replace all missing or broken guards <strong>and</strong>panels.h. Never tamper with safety devices.i. Have a fire extinguisher on h<strong>and</strong> <strong>and</strong> knowhow to use it. Be sure that it is checked regularly(at least monthly) to ensure it is in proper workingorder.j. Check the motion controls for properfunctioning at the start ofeach ~hift or prior to useifthe crane has not been in regular service.Ie. Make certain that no one is working on orclose to the machine before starting the engine orbeginning to move. Accessible areas within theswing radius ofthe rear ofthe rotatingsuperstructure of the crane, either permanently ortemporarily mounted, shall be barricaded in such amanner as to prevent an employee from beingstruck or crushed by the crane.l. Use caution when refueling. Stop theengine; do not permit smoking within 25 ft; neverrefuel near an open flame. Keep metal funnels incontact with the filler tube to prevent static spark.Turn offthe heater before fueling.m. Use both h<strong>and</strong>s to mount <strong>and</strong> dismount.Never get on or offa moving machine, <strong>and</strong> neverjump off, even ifthe machine is stationary.n. H<strong>and</strong> signals from only one person shall beobeyed. However, obey a STOP signal15-17Chapter 15.Construction <strong>Hoisting</strong> <strong>and</strong> <strong>Rigging</strong>Equipment Requirements