DOE-STD-1090-96, DOE Standard Hoisting and Rigging Manual ...

DOE-STD-1090-96, DOE Standard Hoisting and Rigging Manual ...

DOE-STD-1090-96, DOE Standard Hoisting and Rigging Manual ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

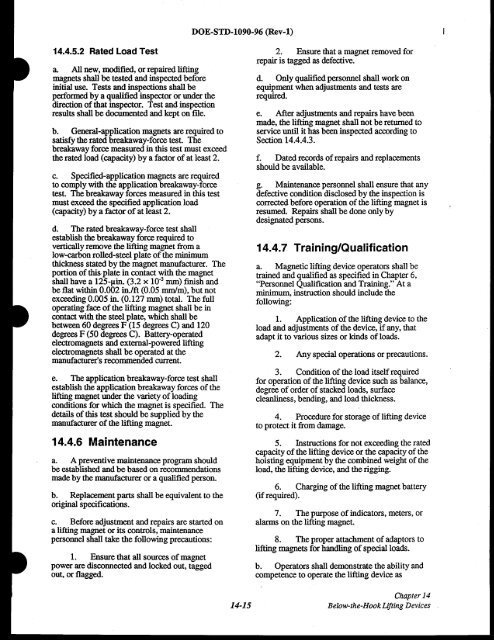

<strong>DOE</strong>-<strong>STD</strong>-I090-<strong>96</strong> (Rev-!)14.4.5.2 Rated Load Testa. All new, modified, orrepaired liftingmagnets shall be tested <strong>and</strong> inspected beforeinitial use. Tests <strong>and</strong> inspections shall beperformed by a qualified inspector or under thedirection ofthat inspector. Test <strong>and</strong> inspectionresults shall be documented <strong>and</strong> kept on file.b. General-application magnets are required tosatisfy the rated breakaway-force test. Thebreakaway force measured in this test must exceedthe rated load (capacity) by a factor ofat least 2.c. Specified-application magnets are requiredto comply with the application breakaway-forcetest The breakaway forces measured in this testmust exceed the specified application load(capacity) by a factor of at least 2.d. The rated breakaway-force test shallestablish the breakaway force required tovertically remove the lifting magnet from alow-carbon rolled-steel plate ofthe minimumthickness stated by the magnet manufacturer. Theportion of this- plate in contact with the magnetshall have a 125-flin. (3.2 x 10- 3 mm) finish <strong>and</strong>be flat within 0.002 in.lft (0.05 mm1m), but notexceeding 0.005 in. (0.127 mm) total. The fulloperating face ofthe lifting magnet shall be incontact with the steel plate, which shall bebetween 60 degrees F (15 degrees C) <strong>and</strong> 120degrees F (50 degrees C). Battery-operatedelectromagnets <strong>and</strong> external-powered liftingelectromagnets shall be operated at themanufacturer's recommended current.e. The application breakaway-force test shallestablish the application breakaway forces of thelifting magnet under the variety ofloadingconditions for which the magnet is specified. Thedetails ofthis test should be supplied by themanufacturer ofthe lifting magnet.14.4.6 Maintenancea. A preventive maintenance program shouldbe established <strong>and</strong> be based on recommendationsmade by the manufacturer or a qualified person.b. Replacement parts shall be equivalent to theoriginal specifications.c. Before adjustment <strong>and</strong> repairs are started ona lifting magnet or its controls, maintenancepersonnel shall take the following precautions:1. Ensure that all sources ofmagnetpower are disconnected <strong>and</strong> locked out, taggedout, or flagged.2. Ensure that a magnet removed forrepair is tagged as defective.d. Only qualified personnel shall work onequipment when adjustments <strong>and</strong> tests arerequired.e. Mer adjustments <strong>and</strong> repairs have beenmade, the lifting magnet shall not bereturned toservice until it has been inspected according toSection 14.4.4.3.f. Dated records ofrepairs <strong>and</strong> replacementsshould be available.g. Maintenance personnel shall ensure that anydefective condition disclosed by the inspection iscorrected before operation ofthe lifting magnet isresumed. Repairs shall be done only bydesignated persons.14.4.7 Training/Qualificationa. Magnetic lifting device operators shall betrained <strong>and</strong> qualified as specified in Chapter 6,"Personnel Qualification <strong>and</strong> Training." At aminimum, instruction should include thefollowing:1. Application ofthe lifting device to theload <strong>and</strong> adjustments ofthe device, ifany, thatadapt it to various sizes or kinds ofloads.2. Any special operations or precautions.3. Condition ofthe load itselfrequiredfor operation of the lifting device such as balance,degree of order ofstacked loads, surfacecleanliness, bending, <strong>and</strong> load thickness.4. Procedure for storage oflifting deviceto protect it from damage.5. Instructions for not exceeding the ratedcapacity ofthe lifting device or the capacity of thehoisting equipment by the combined weight oftheload, the lifting device, <strong>and</strong> the rigging.6. Charging ofthe lifting magnet battery(ifrequired).7. The purpose ofindicators, meters, oralarms on the lifting magnet.8. The proper attachment of adaptors tolifting magnets for h<strong>and</strong>ling ofspecial loads.b. Operators shall demonstrate the ability <strong>and</strong>competence to operate the lifting device as14-15Chapter 14Below-tile-HookLifting Devices