DOE-STD-1090-96, DOE Standard Hoisting and Rigging Manual ...

DOE-STD-1090-96, DOE Standard Hoisting and Rigging Manual ...

DOE-STD-1090-96, DOE Standard Hoisting and Rigging Manual ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

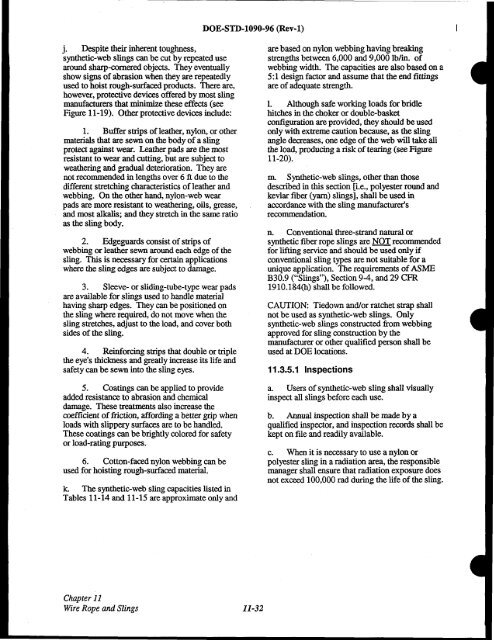

<strong>DOE</strong>-<strong>STD</strong>-I090-<strong>96</strong> (Rev-I)j. Despite their inherent toughness,synthetic-web slings canbe cut byrepeated usearound sharp-cornered objects. They eventuallyshow signs of abrasion when they are repeatedlyused to hoist rough-surfaced products. There are,however, protective devices offered by most slingmanufacturers that minimize these effects (seeFigure 11-19). Other protective devices include:1. Buffer strips ofleather, nylon, or othermaterials that are sewn on the body ofa slingprotect against wear. Leather pads are the mostresistant to wear <strong>and</strong> cutting, but are subject toweathering <strong>and</strong> gradual deterioration. They arenot recommended in lengths over 6 ft due to thedifferent stretching characteristics ofleather <strong>and</strong>webbing. On the other h<strong>and</strong>, nylon-web wearpads are more resistant to weathering, oils, grease,<strong>and</strong> most alkalis; <strong>and</strong> they stretch in the same ratioas the sling body.2. Edgeguards consist ofstrips ofwebbing or leather sewn around each edge ofthesling. This is necessary for certain applicationswhere the sling edges are subject to damage.3. Sleeve- or sliding-tube-type wear padsare available for slings used to h<strong>and</strong>le materialhaving sharp edges. They can be positioned onthe sling where required, do not move when thesling stretches, adjust to the load, <strong>and</strong> cover bothsides ofthe sling.4. Reinforcing strips that double or triplethe eye's thickness <strong>and</strong> greatly increase its life <strong>and</strong>safety can be sewn into the sling eyes.5. Coatings can be applied to provideadded resistance to abrasion <strong>and</strong> chemicaldamage. These treatments also increase thecoefficient offriction, affording a better grip whenloads with slippery surfaces are to beh<strong>and</strong>led.These coatings can bebrightly colored for safetyor load-rating purposes.6. Cotton-faced nylon webbing can beused for hoisting rough-surfaced material.k. The synthetic-web sling capacities listed inTables 11-14 <strong>and</strong> 11-15 are approximate only <strong>and</strong>are based on nylon webbing having breakingstrengths between 6,000 <strong>and</strong> 9,000 lb/in. ofwebbing width. The capacities are also based on a5:1 design factor <strong>and</strong> assume that the end fittingsare of adequate strength.1. Although safe working loads for bridlehitches in the choker or double-basketconfiguration are provided, they should be usedonly with extreme caution because, as the slingangle decreases, one edge ofthe web will take allthe load, producing a risk oftearing (see Figure11-20).m. Synthetic-web slings, other than thosedescribed in this section [Le., polyester round <strong>and</strong>kevlar fiber (yam) slings], shall be used inaccordance with the sling manufacturer'srecommendation.n. Conventional three-str<strong>and</strong> natural orsynthetic fiber rope slings are NOT recommendedfor lifting service <strong>and</strong> should be used only ifconventional sling types are not suitable for aunique application. The requirements ofASMEB30.9 ("Slings"), Section 9-4, <strong>and</strong> 29 CFR191O.184(h) shall be followed.CAUTION: Tiedown <strong>and</strong>/or ratchet strap shallnot be used as synthetic-web slings. Onlysynthetic-web slings constructed from webbingapproved for sling construction by themanufacturer or other qualified person shall beused at <strong>DOE</strong> locations.11.3.5.1 Inspectionsa. Users ofsynthetic-web sling shall visuallyinspect all slings before each use.b. Annual inspection shall be made by aqualified inspector, <strong>and</strong> inspection records shall bekept on file <strong>and</strong> readily available.c. When it is necessary to use a nylon orpolyester sling in a radiation area, the responsiblemanager shall ensure that radiation exposure doesnot exceed 100,000 rad during the life ofthe sling.Chapter 11Wire Rope <strong>and</strong> Slings 11-32