DOE-STD-1090-96, DOE Standard Hoisting and Rigging Manual ...

DOE-STD-1090-96, DOE Standard Hoisting and Rigging Manual ...

DOE-STD-1090-96, DOE Standard Hoisting and Rigging Manual ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

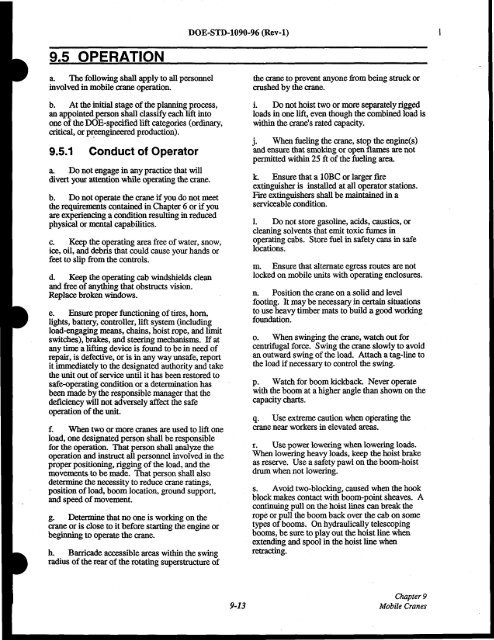

<strong>DOE</strong>-<strong>STD</strong>-<strong>1090</strong>-<strong>96</strong> (Rev-l)9.5 OPERATIONa. The following shall apply to all personnelinvolved in mobile crane operation.b. At the initial stage ofthe planning process,an appointed person shall classify each lift intoone of the <strong>DOE</strong>-specified lift categories (ordinary,critical, orpreengineered production).9.5.1Conduct of Operatora. Do not engage in any practice that willdivert your attention while operating the crane.b. Do not operate the craneifyou do not meetthe requirements contained in Chapter 6 orifyouare experiencing a condition resulting in reducedphysical or mental capabilities.c. Keep the operating area free ofwater, snow,ice, oil, <strong>and</strong> debris that could cause your h<strong>and</strong>s orfeet to slip from the controls.d. Keep the operating cab windshields clean<strong>and</strong> free ofanything that obstructs vision.Replace broken windows.e. Ensure proper functioning oftires, horn,lights, battery, controller, lift system (includingload-engaging means, chains, hoist rope, <strong>and</strong> limitswitches), brakes, <strong>and</strong> steering mechanisms. Ifatany time a lifting device is found to be in need ofrepair, is defective, or is in any way unsafe, reportit immediately to the designated authority <strong>and</strong> takethe unit out ofservice until it has been restored tosafe-operating condition or a determination hasbeen made by the responsible manager that thedeficiency will not adversely affect the safeoperation ofthe unit.f. When two or more cranes are used to lift oneload, one designated person shall be responsiblefor the operation. That person shall analyze theoperation <strong>and</strong> instruct all personnel involved in theproper positioning, rigging ofthe load, <strong>and</strong> themovements to be made. That person shall alsodetermine the necessity to reduce crane ratings,position ofload, boom location, ground support,<strong>and</strong> speed ofmovement.g. Determine that no one is working on thecrane or is close to it before starting the engine orbeginning to operate the crane.h. Barricade accessible areas within the swingradius ofthe rear ofthe rotating superstructure ofthe crane to prevent anyone from being struck orcrushed by the crane.i. Do not hoist two or more separately riggedloads in one lift, even though the combined load iswithin the crane's rated capacity.j. When fueling the crane, stop the engine(s)<strong>and</strong> ensure that smoking or open flames are notpennitted within 25 it of the fueling area.k Ensure that a 10BC or larger fireextinguisher is installed at all operator stations.Fire extinguishers shall be maintained in aserviceable condition.l. Do not store gasoline, acids, caustics, orcleaning solvents that emit toxic fumes inoperating cabs. Store fuel in safety cans in safelocations.In. Ensure that alternate egress routes are notlocked on mobile units with operating enclosures.n. Position the crane on a solid <strong>and</strong> levelfooting. It may benecessary in certain situationsto use heavy timber mats to build a good workingfoundation.o. When swiIiging the crane, watch out forcentrifugal force. Swing the crane slowly to avoidan outward swing ofthe load. Attach a tag-line tothe load ifnecessary to control the swing.p. Watch for boom kickback· Never operatewith the boom at a higher angle than shown on thecapacity charts.q. Use extreme caution when operating thecrane near workers in elevated areas.r. Use power lowering when lowering loads.When lowering heavy loads, keep the hoist brakeas reserve. Use a safety pawl on the boom-hoistdrum when not lowering.s. Avoid two-blocking, caused when the hookblock makes contact with boom-point sheaves. Acontinuing pull on the hoist lines can break therope or pull the boom back over the cab on sometypes ofbooms. On hydraulically telescopingbooms, be sure to play out the hoistline whenextending <strong>and</strong> spool in the hoist line whenretracting.9-13Chapter 9Mobile Cranes