DOE-STD-1090-96, DOE Standard Hoisting and Rigging Manual ...

DOE-STD-1090-96, DOE Standard Hoisting and Rigging Manual ...

DOE-STD-1090-96, DOE Standard Hoisting and Rigging Manual ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

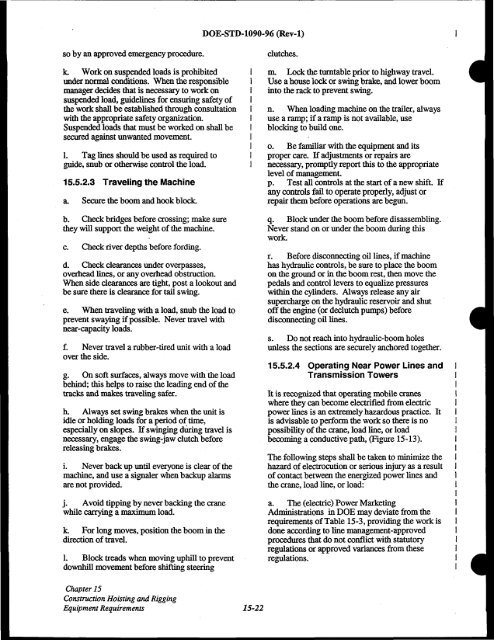

<strong>DOE</strong>-<strong>STD</strong>-I090-<strong>96</strong> (Rev-I)so by an approved emergency procedure.k. Work on suspended loads is prohibitedunder normal conditions. When the responsiblemanager decides that is necessary to work onsuspended load, guidelines for ensuring safety ofthe work shall be established through consultationwith the appropriate safety organization.Suspended loads that must be worked on shall besecured against unwanted movement.1. Tag lines should be used as required toguide, snub or otherwise control the load.15.5.2.3 Traveling the Machinea. Secure the boom <strong>and</strong> hookblock.b. Check bridges before crossing; make surethey will support the weight ofthe machine.c. Check river depths before fording.d. Check clearances under overpasses,overhead lines, or any overhead obstruction.When side clearances are tight, post a lookout <strong>and</strong>be sure there is clearance for tail swing.e. When traveling with a load, snub the load toprevent swaying ifpossible. Never travel withnear-capacity loads.f. Never travel a rubber-tired unit with a loadover the side.g. On soft surfaces, always move with the loadbehind; this helps to raise the leading end ofthetracks <strong>and</strong> makes traveling safer.h. Always set swing brakes when the unit isidle or holding loads for a period oftime,especially on slopes. Ifswinging dUring travel isnecessary, engage the swing-jaw clutch beforereleasing brakes.i. Never back up until everyone is clear ofthemachine, <strong>and</strong> use a signaler when backup alarmsare not provided.j. Avoid tipping bynever backing the cranewhile carrying a maximum load.k. For long moves, position the boom in thedirection oftravel.1. Block treads when moving uphill to preventdownhill movement before shifting steeringclutches.m. Lock the turntable prior to highway travel.Use a house lock or swing brake, <strong>and</strong> lower boominto the rack to prevent swing.n. When loading machine on the trailer, alwaysuse a ramp; ifa ramp is not available, useblocking to build one.o. Be familiar with the equipment <strong>and</strong> itsproper care. Ifadjustments or repairs arenecessary, promptly report this to the appropriatelevel ofmanagement.p. Test all controls at the start of a new shift. Ifany controls fail to operate properly, adjust orrepair them before operations are begun.q. Block under the boom before disassembling.Never st<strong>and</strong> on or under the boom during thiswork.r. Before disconnecting oil lines, ifmachinehas hydraulic controls, be sure to place the boomon the ground or in the boom rest, then move thepedals <strong>and</strong> control levers to equalize pressureswithin the cylinders. Always release any airsupercharge on the hydraulic reservoir <strong>and</strong> shutoffthe engine (or declutch pumps) beforedisconnecting oil lines.s. Do not reach into hydraulic-boom holesunless the sections are securely anchored together.15.5.2.4 Operating Near Power Lines <strong>and</strong>Transmission TowersIt is recognized that operating mobile craneswhere they can become electrified from electricpower lines is an extremely hazardous practice. Itis advisable to perform the work so there is nopossibility ofthe crane, load line, or loadbecoming a conductive path, (Figure 15-13).The following steps shall be taken to minimize thehazard ofelectrocution or serious injury as a resultofcontact between the energized power lines <strong>and</strong>the crane, load line, or load:a. The (electric) Power MarketingAdministrations in<strong>DOE</strong> may deviate from therequirements ofTable 15-3, providing the work isdone according to line management-approvedprocedures that do not conflict with statutoryregulations or approved variances from theseregulations.Chapter 15Construction <strong>Hoisting</strong> <strong>and</strong> <strong>Rigging</strong>Equipment Requirements 15-22