PROJECT MANUAL Specifications Seafood Removal Walmart Store No 1186 Liberty TX

Specs - Home

Specs - Home

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

equirement as directed by Wal-Mart Construction Manager to verify compliance. Provide test report to<br />

Wal-Mart Construction Manager.<br />

2. Conduct Concrete strength tests:<br />

a. During the initial 24 hours (plus or minus 8 hours) after molding, the temperature immediately<br />

adjacent to the specimens shall be maintained in the range of 60 to 80 degrees F. Control loss of<br />

moisture from the specimens by shielding from the direct rays of the sun and from radiant heating<br />

devices.<br />

b. Specimens transported prior to 48 hours after molding shall not be demolded, but shall continue<br />

initial curing at 60 to 80 degrees F until time for transporting.<br />

c. Specimens transported after 48 hours age shall be demolded in 24 hours (plus or minus 8 hours).<br />

Curing shall then be continued but in saturated limewater at 73 degrees (plus or minus 3 degrees F)<br />

until the time of transporting.<br />

d. During transportation, protect the specimens with suitable cushioning material to prevent damage<br />

from jarring. During cold weather, protect specimens from freezing with suitable insulation material.<br />

Transportation time shall not exceed four hours.<br />

e. Date test cylinders and number consecutively. Give each cylinder of each set an identifying letter<br />

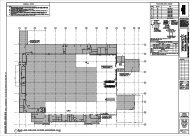

(i.e. A, B, C, D). Prepare a sketch of the building plan for each test set identifying location of placed<br />

concrete.<br />

f. Test one cylinder (A) at 7 days for information. If the compressive strength of the concrete sample is<br />

equal to or above the 28 day specified strength, test another cylinder (B) at 7 days. The average of<br />

the breaks shall constitute the compressive strength of the concrete sample.<br />

g. Test two cylinders (C and D) at 28 days and the average of the breaks shall constitute the<br />

compressive strength of the concrete sample.<br />

3. In addition to required information noted previously in this Section, record the following information on<br />

concrete compression reports:<br />

a. Test cylinder number and letter.<br />

b. Specific foundations or structures covered by this test.<br />

c. Proportions of concrete mix or mix identification.<br />

d. Measure uncapped concrete cylinder weight.<br />

e. Specified compressive strength.<br />

f. Tested compressive strength.<br />

g. Concrete plastic unit weight.<br />

h. Name of technician securing samples.<br />

i. Curing conditions for concrete strength test specimens (field and laboratory).<br />

j. Date strength specimens transported to laboratory.<br />

k. Age of strength specimens when tested.<br />

l. Type of fracture during test.<br />

m. Curing condition for concrete strength test specimens (field and laboratory)<br />

D. Field Testing<br />

1. Perform tests noted in Table A, at defined intervals, and provide test reports with location of each<br />

placement represented to the building official and to the Wal-Mart Construction Manager.<br />

2. If any test required in Table A fails, repeat failed test for each following truck until compliance is met.<br />

3. Test concrete temperature hourly when air temperature is 40 F and below or 80 F and above.<br />

4. CTL shall notify Contractor to reject concrete if air content is over 3%.<br />

5. When pumping concrete, take samples for tests at point of delivery from pumping line in addition to first<br />

slump test noted above for concrete with water-reducer.<br />

6. Stockpile Sieve Analysis: Immediately before first concrete production and later as directed by Wal-Mart<br />

Construction Manager, obtain samples at concrete plant of aggregate size groups used in pertinent mix to<br />

verify mix design submittals. Samples shall be obtained from bins as close as possible in time and space to<br />

their introduction into mixer. Concrete supplier and aggregate producer shall have representatives available<br />

to assist testing agency in obtaining representative samples. Perform sieve analysis on each aggregate size<br />

group, using sieve sizes specified herein. Provide following test data: percent passing each sieve,<br />

cumulative percent retained on each sieve, percent retained on each sieve, fineness modulus, and combined<br />

03312-23<br />

<strong>Walmart</strong> #<strong>1186</strong> – <strong>Liberty</strong>, <strong>TX</strong> 04/20/11<br />

CMA/10118.034