PROJECT MANUAL Specifications Seafood Removal Walmart Store No 1186 Liberty TX

Specs - Home

Specs - Home

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1. Use of 60-grit metal bonded diamond heads is allowed for removal of heavy mastic only and must be approved<br />

in writing by the <strong>Walmart</strong> Construction Manager and <strong>Walmart</strong> Concrete Consultant.<br />

2. Do not expose concrete coarse aggregate.<br />

3. Clean slab with auto scrubber.<br />

B. Polish slab with 150-grit metal bonded diamond heads.<br />

C. Apply un-tinted (colorless) densifier per manufacturer’s written instructions.<br />

1. Apply one coat with specified sprayer and tip, at a rate recommended by manufacturer.<br />

2. Apply to one panel at a time, without pause or interruption, using circular motion and sweeping application.<br />

3. Draw densifier out across slab with fine bristle smooth surface shop broom.<br />

4. Allow densifier to dry approximately 1 hour.<br />

D. Burnish with diamond impregnated or natural hair burnishing pads, removing all densifier residue.<br />

E. Mix concrete silicate colorant and densifier at a dilution of 12 ounces colorant per gallon of densifier. Vary dilution<br />

rate as required to match existing adjacent slab concrete panels.<br />

F. Apply tinted densifier per manufacturer’s written instructions as required to eliminate or minimize appearance of<br />

pattern of removed plank flooring.<br />

1. Apply one coat with specified sprayer and tip, at a rate recommended by manufacturer.<br />

2. Apply to one panel at a time, without pause or interruption, using circular motion and sweeping application.<br />

3. Draw densifier out across slab with fine bristle smooth surface shop broom.<br />

4. Allow densifier to dry approximately 1 hour.<br />

G. Burnish with diamond impregnated or natural hair burnishing pads, removing all densifier residue.<br />

H. Obtain approval of <strong>Walmart</strong> Concrete Consultant prior to proceeding to stain guard application.<br />

3.4 PROTECTIVE SURFACE TREATMENT (STAIN GUARD) APPLICATION<br />

A. Area to be treated: Subsequent to densifier application, apply protective surface treatment over surfaces to which<br />

densifier has been applied and has dried.<br />

B. Use proper Personal Protective Equipment (PPE) when applying lithium stain guard and/or burnishing.<br />

C. Application:<br />

1. Apply in accordance with manufacturer’s published instructions.<br />

2. Apply first coat at the rate of 2,000-2,500 sq. ft. per gallon, per manufacturer’s recommendation (DO NOT<br />

OVER APPLY).<br />

3. Use applicator pad, pre-wetted with stain guard, to pull material out to create a thin film prior to drying.<br />

4. Remove product completely from areas of over application, as evidenced by surface streaking, and replace<br />

with unused stain guard.<br />

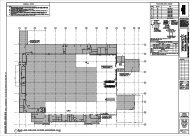

5. Apply second coat of stain guard at all high traffic areas identified on the drawings at the rate of 2,500 sq.<br />

ft. per gallon.<br />

D. High speed burnish:<br />

1. After each application of stain guard is dry, burnish surface.<br />

2. Burnish at a slow movement pace using high speed machine with 800 grit diamond impregnated or hog’s<br />

hair burnishing pads.<br />

3. Burnish with several passes. Make each progressive pass at 90 degrees from previous pass.<br />

4. Burnishing, pad type, and pace of forward movement shall combine to develop a minimum floor surface<br />

temperature of 91-degrees F directly below the burnishing pad as continuously measured by the operator<br />

during installation.<br />

03367-8<br />

<strong>Walmart</strong> #<strong>1186</strong> – <strong>Liberty</strong>, <strong>TX</strong> 04/2<br />

CMA/10118.034