PROJECT MANUAL Specifications Seafood Removal Walmart Store No 1186 Liberty TX

Specs - Home

Specs - Home

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1. Pentra-Guard (HP) by Convergent Concrete Technologies.<br />

2. Consolideck LS Guard by Prosoco.<br />

3. SS Duraguard by Seal Source.<br />

B. Lithium Stain Guard Application Material:<br />

1. Manufacturer approved sprayer and sprayer tip for application of lithium stain guard.<br />

2. Manufacturer approved pads for application of lithium stain guard.<br />

a. Professional Mighty Mop 077 by Quickie.<br />

b. 24” Microfiber Wet Room Pad by Rubbermaid.<br />

c. Other pads as approved by manufacturer of protective surface treatment.<br />

C. Sprayer: Manufacturer approved high volume, low pressure sprayer and sprayer tip.<br />

2.9 JOINT FILLER<br />

1. Polyurea joint filler as specified in Section 03905.<br />

2. Color: Match polished slab surface. Dry sample shall be approved by Wal-Mart Construction Manager.<br />

PART 3 - EXECUTION<br />

3.1 EXAMINATION<br />

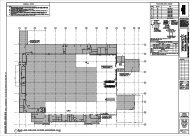

A. Examine concrete slab in the presence of the certified applicator and Wal-Mart Construction Manager. Identify all<br />

joint filler replacement and repairs required for existing slab defects on Floor Burnishing Plan.<br />

3.2 PREPARATION<br />

A. Remove existing resilient plank flooring where shown on Drawings.<br />

B. Remove joint filler from existing slab joints in areas receiving work specified herein and install polyurea joint filler<br />

as specified in section 03905.<br />

C. Repair slab defects in areas receiving work specified herein in accordance with section 03905.<br />

D. Adjust existing plumbing cleanouts in area to be treated.<br />

1. If existing cleanout has height adjustment threads, core drill slab, centering bit on cleanout, to a depth allowing<br />

activation of the threads without damaging fixture or plumbing. Limit over-coring to provide maximum<br />

½” joint between cleanout and existing concrete and fill with polyurea joint filler.<br />

2. If existing cleanout lacks height adjustment threads, core drill slab, centering bit on cleanout, 2-inches outside<br />

perimeter of cleanout to a depth allowing lowering of the cleanout. Pack joint with non-shrink grout to<br />

1” below finish floor and fill remainder of joint with polyurea joint filler.<br />

E. Cleaning:<br />

1. Remove curing, sealing and coating agents, oil, breaking compound residue, wax, and grease by mechanically<br />

scraping off heavy deposits.<br />

2. Remove mildew by scrubbing with solution of trisodium phosphate and bleach. Rinse with clean water.<br />

3. Thoroughly rinse area to be treated with clean water to remove all soap residue and contaminants. Squeegee<br />

dry.<br />

F. Protect adjacent surfaces as required to prevent damage by products and procedures specified herein.<br />

3.3 APPLICATION OF DENSIFIER<br />

A. Grind slab with 80-grit metal bonded diamond heads<br />

03367-7<br />

<strong>Walmart</strong> #<strong>1186</strong> – <strong>Liberty</strong>, <strong>TX</strong> 04/2<br />

CMA/10118.034